Fixed multi-head thickness determining machine

A fixed, multi-head technology, used in machine tools, stone processing equipment, grinders and other directions suitable for grinding workpiece planes, can solve the problems of small cutting area of the fixed thickness plate, unstable thickness setting mechanism, inconvenient use, etc., to achieve cutting The effect of stable process, low labor intensity and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to better understand the technical solutions of the present invention, the embodiments provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

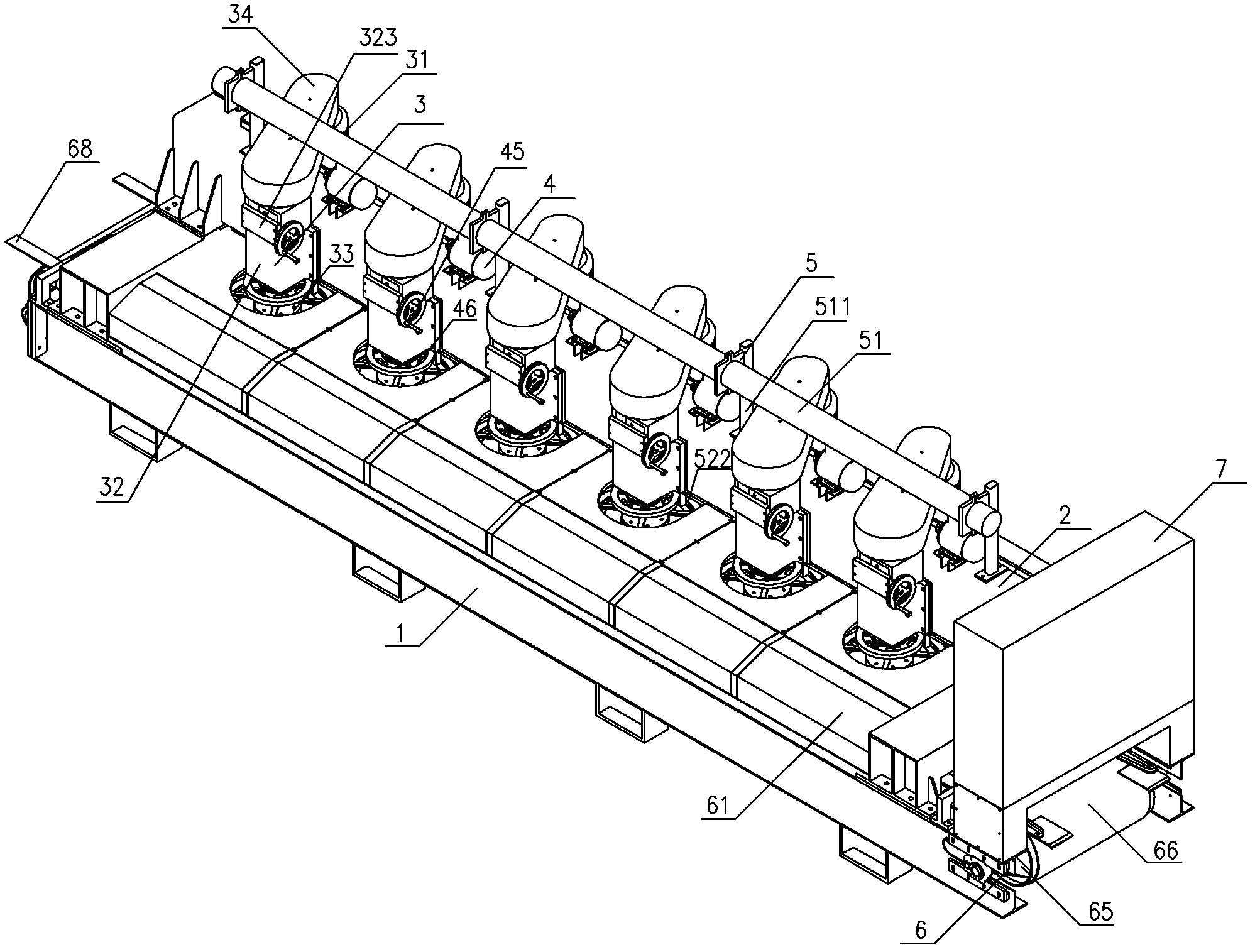

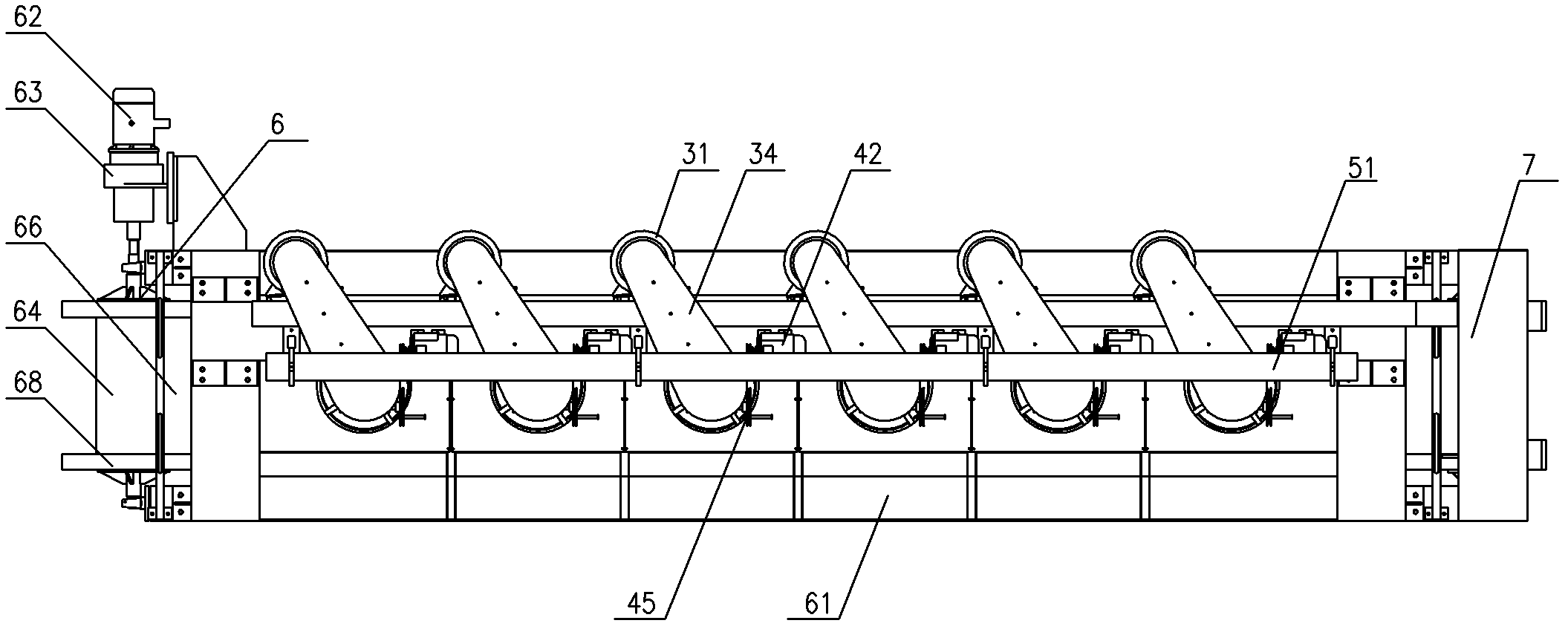

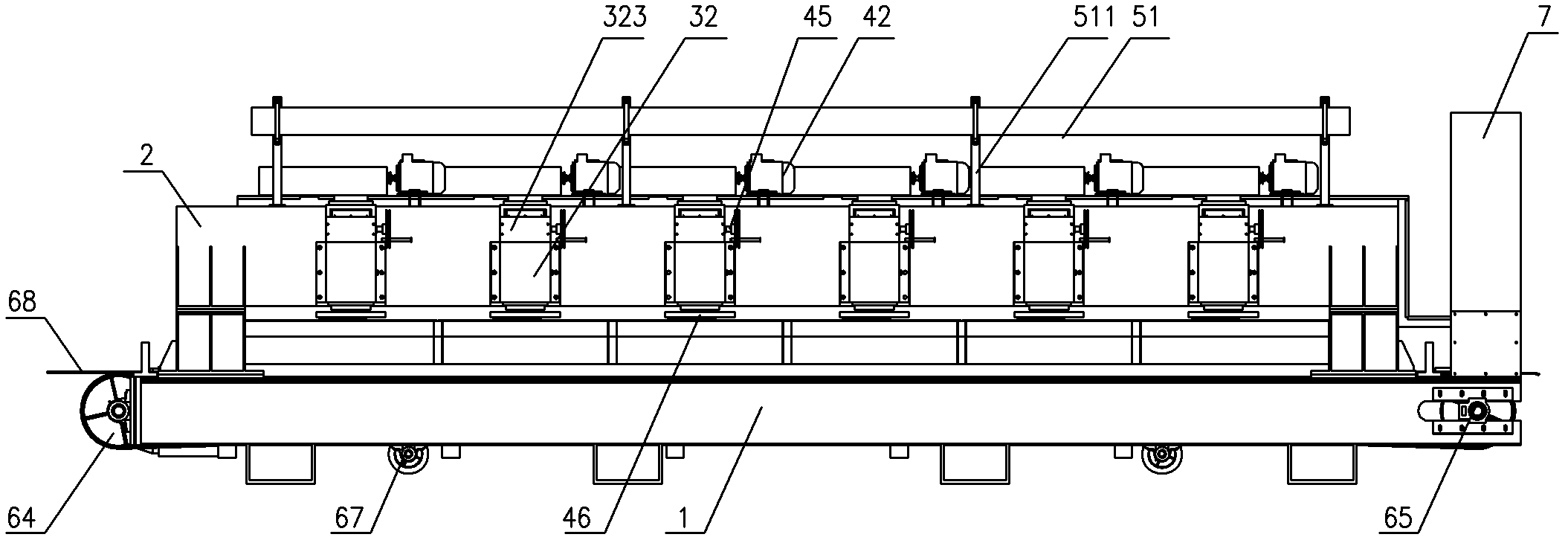

[0022] refer to Figure 1 to Figure 5 As shown, the fixed multi-head thickness calibrating machine includes: frame 1, beam 2, thickness calibrating mechanism 3, lifting mechanism 4, automatic water supply system 5, transmission mechanism 6 and electric control box 7;

[0023] The beam 2 is erected horizontally above the frame 1;

[0024] The thickness-fixing mechanism 3 has six groups and is fixedly arranged on the beam 2, including a thickness-fixing motor 31, a spindle box 32, a milling disc 33 and a belt shield 34, and the upper end of the main shaft 321 in the spindle box 32 is provided with a main shaft pulley 322, The lower end is connected with the milling disc 33, the spindle box 32 is provided with a scale 323 for displaying the height of the main sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com