Fluoro-ethylene polymer (FPE) membrane for solar battery rear panel and preparation method thereof

A solar cell and backplane technology, applied in the field of solar cells, can solve problems such as poor composite strength, poor interlayer composite strength, and high price, and achieve the effects of good weather resistance, excellent barrier performance, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

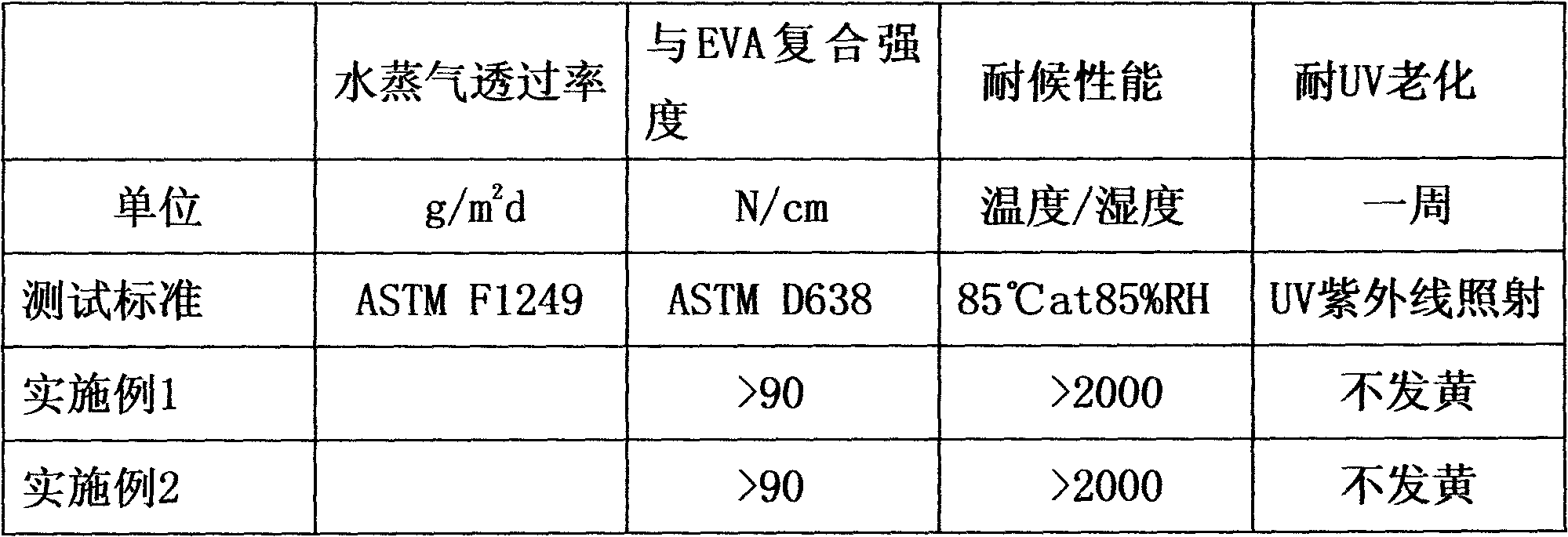

Examples

Embodiment 1

[0023] An FPE film for a solar cell backplane and a preparation method thereof. The FPE film has a three-layer structure, including an outer film layer composed of PVDF / PMMA, a high weather resistance HDPE intermediate film layer, and a high weather resistance LLDPE outer film layer in sequence. FPE The thickness of the film is 25 μm, the thickness of the outer film layer composed of PVDF / PMMA is 5 μm, the thickness of the high weather resistance HDPE middle film layer is 10 μm, and the thickness of the high weather resistance LLDPE outer film layer is 10 μm.

[0024] In the middle film layer of high weather resistance HDPE and the outer film layer of high weather resistance LLDPE, 0.5% of 2,6-tertiary butyl-4-methylphenol and 0.5% of o-hydroxybenzoic acid ester are added and 0.1% of bis-2,2,6,6-tetramethylpiperidinol sebacate, and 0.1-1.0% of silicone leveling agent is added to the FPE film by weight percentage.

[0025] The color of the FPE film of the present invention can ...

Embodiment 2

[0030] An FPE film for a solar cell backplane and a preparation method thereof. The FPE film has a three-layer structure, including an outer film layer composed of PVDF / PMMA, a high weather resistance HDPE intermediate film layer, and a high weather resistance LLDPE outer film layer in sequence. FPE The film thickness is 125 μm, of which the thickness of the outer film layer composed of PVDF / PMMA is 25 μm, the thickness of the high weather resistance HDPE middle film layer is 50 μm, and the thickness of the high weather resistance LLDPE outer film layer is 50 μm.

[0031] In the high weather resistance HDPE middle film layer and the high weather resistance LLDPE outer film layer, calculated by weight percentage, add 0.5% bis (3,5-tertiary butyl-4-hydroxyphenyl) sulfide, 0.5% 2 , 4-dihydroxybenzophenone and 0.1% of bis(2,2,6,6-pentamethyl-4-piperidinyl) sebacate, in the FPE film added 0.1- 1.0% acrylate leveling agent.

[0032] The color of the FPE film of the present inventio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap