Welded assembly of lower cross beam of car

A technology for beams and cars, which is applied in the field of welding assembly of lower beams of cars, can solve the problems of improper selection of beam materials, insufficient installation strength, and insufficient strength of parts, etc., and achieves good coating processability, symmetrical structure design, and improved installation strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

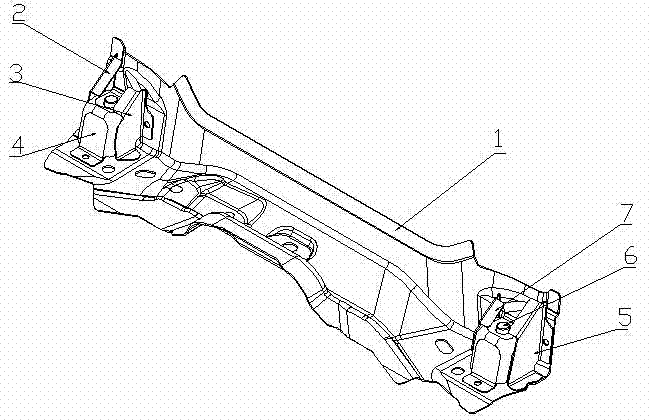

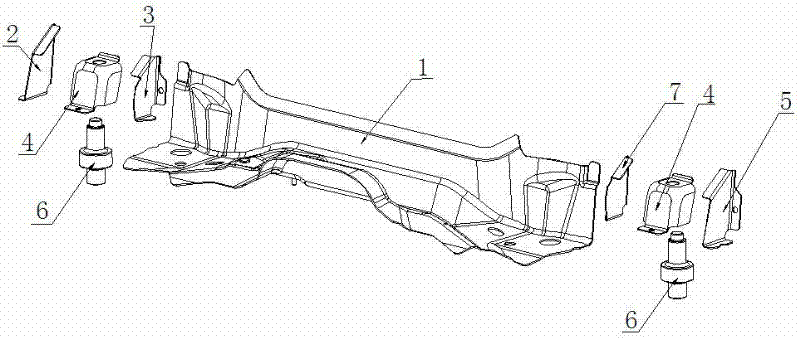

[0022] see figure 1 , figure 2 The shown welding assembly of a lower beam of a car comprises a lower beam body 1 and two mounting threaded pipes 6 which are vertically and fixedly connected to the left end and the right end of the lower beam body respectively;

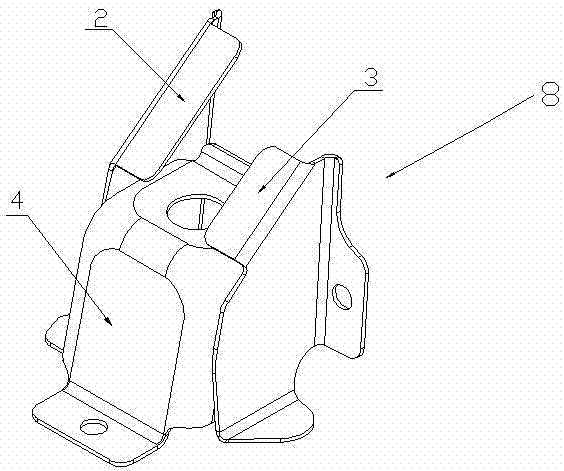

[0023] The first crossbeam reinforcement assembly 8 is set outside the installation threaded pipe 6 at the left end of the lower crossbeam body 1, and the second crossbeam reinforcement assembly is sleeved outside the installation threaded pipe 6 at the right end of the lower crossbeam body 1; the second crossbeam reinforcement assembly The structure of the member is the same as that of the first beam reinforcement assembly 8, and they are left-right symmetrical. This not only has good versatility, but also saves cost; it not only meets the requirements of automobile strength and rigidity, but also achieves ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com