Roller built in double-brake flange for large towing winch and manufacturing method thereof

A double-brake wheel and manufacturing method technology, which is applied in the manufacture of tools, ships, welding equipment, etc., can solve the problems of heavy weight, high manufacturing difficulty, and easy to increase difficulty in use, and achieve light weight, low manufacturing difficulty, and reduce manufacturing costs. The effect of procurement difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0059] 2. Regarding the preheating and annealing in "Preparation of end-disk integration":

[0060] In the present invention, during the assembly process of the end plate integration 2 and the cylinder body 1, before and after the welding of the side plate 21 and the cylinder shaft 23, they need to be preheated and annealed. The reason is that:

[0061] The side plate 21 and the cylindrical shaft 23 are generally made of medium carbon high-strength steel, and the thickness of the side plate 21 and the cylindrical shaft 23 is relatively thick. In order to ensure the welding quality and prevent cracks on the side plate 21 and the cylindrical shaft 23 during welding, this The invention preheats and anneals the side plate 21 and the cylinder shaft 23 before and after welding, so that not only can effectively avoid the occurrence of cracks, but also can obtain a better welding effect and ensure the firmness of the connection.

[0062] 3. About the correction in "Welding and Correct...

Embodiment

[0065] The present invention is applied to the test and verification of a 500-ton towline crane. The height of the drum is 3014mm, the length is 4270mm, and the weight is 42.5 tons. The following describes this embodiment from the two aspects of the overall structure and the manufacturing method:

[0066] the whole frame:

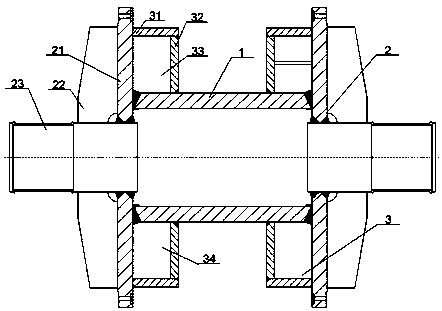

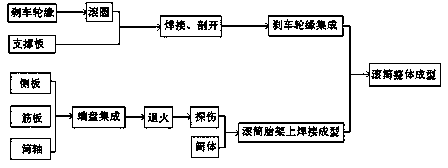

[0067] see figure 1 , a drum with built-in double brake rims for a large towing machine, the drum includes a cylinder body 1, an integrated end disc 2 and an integrated brake rim 3, and the integrated brake rim 3 and the integrated end disc 2 are set in one-to-one correspondence , and the brake rim integration 3 is located on the inner side of the end disc integration 2;

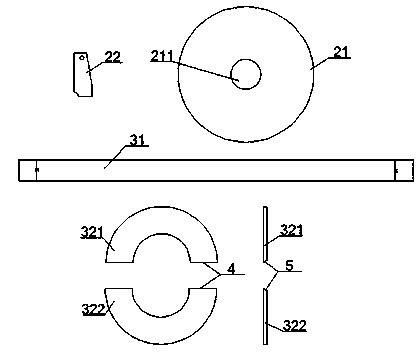

[0068] The end plate integration 2 includes a side plate 21, a rib plate 22 and a cylinder shaft 23, one side of the side plate 21 is connected with the cylinder body 1, and the other side is connected with eight rib plates 22, and the eight rib plates 22 are evenly arranged along the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com