Method for folding rhombic ship

A folding method and diamond-shaped technology, applied to rigid containers, containers, packaging, etc., can solve the problems of not being able to float in water, paper damage, big turning over, etc., and achieve the effect of not being easy to lose shape, simple to make, and unique in shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

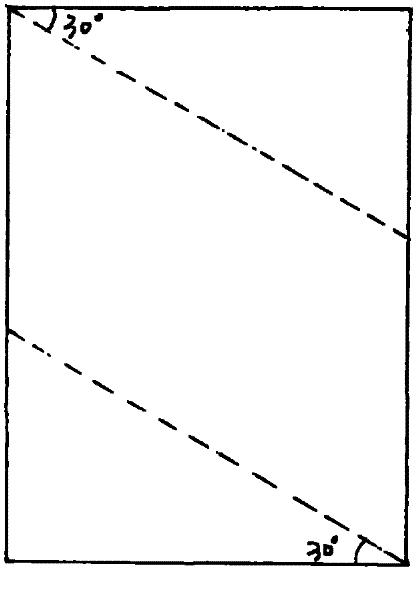

[0016] Example: take a rectangular paper with a ratio of length, length and width to width, such as A4 copy paper 29cm×21cm, and make folding lines. The short dashed line is the positive folding line of the front side, the solid line plus circle is the reverse folding line of the back side, and the dotted line is the perspective line ; From the upper left corner and the lower right corner of the rectangular paper, make two oblique positive folding lines that form an angle of 30 degrees with the wide side of the rectangular paper, so that the rectangular paper is two right-angled triangles at the upper right, lower left, and a parallelogram in the middle ;Such as figure 1 ;

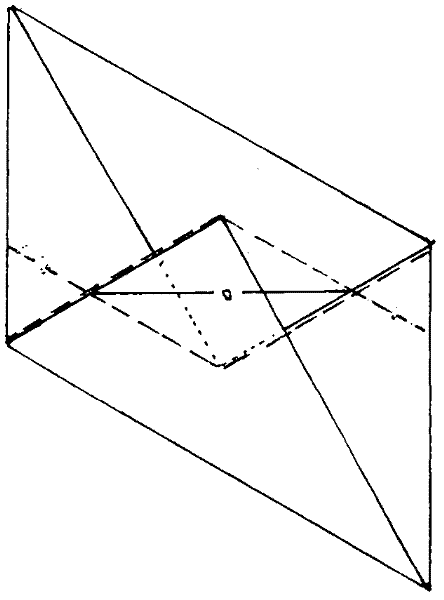

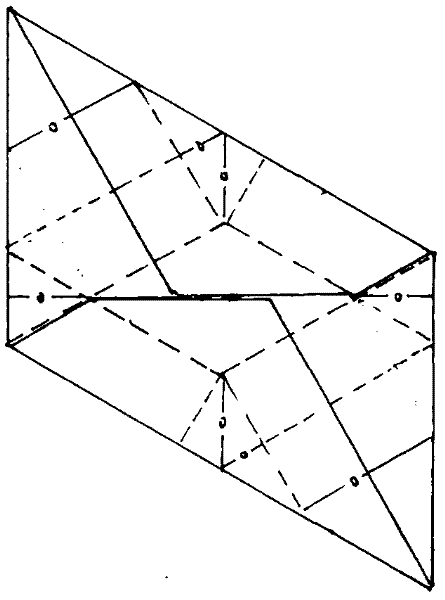

[0017] Fold according to the two oblique positive folding lines, and fold the two right triangles toward the middle, and the rectangular paper is deformed into a parallelogram. A part of the right angle of the right triangle overlaps in the middle of the parallelogram; one of the two opposite right triang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com