Novel feeding machine

A feeding machine, a new type of technology, applied in conveyors, vibrating conveyors, transportation and packaging, etc., can solve problems such as easy blockage, uncontrollable output, empty materials, etc., and achieve low power consumption and no flushing , low noise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

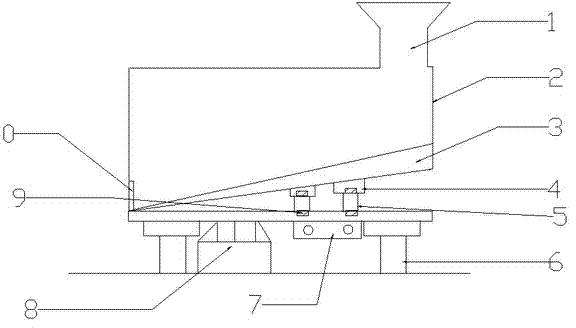

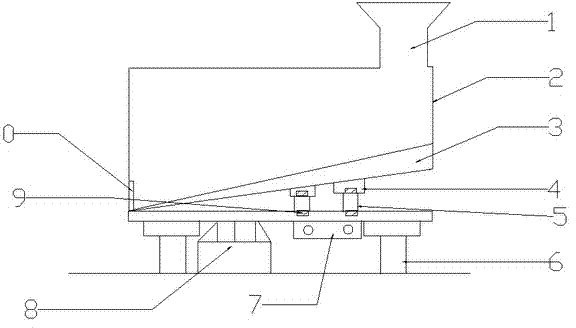

[0014] figure 1 The reference signs shown are as follows: hopper 1, vibrating frame 2, chute 3, backing plate 4, support spring 5, crossties 6, electromagnetic switch group 7, vibration motor 8, electromagnetic plate 9, discharge port 10.

[0015] A new type of feeding machine, comprising a vibrating frame 2, a vibrating motor 8, a hopper 1, and a discharge port 10, characterized in that: the hopper 1 is located at the upper right end of the vibrating frame 2, and the discharge port 10 is located at the bottom of the vibrating frame 2 The lower left end; the lower end of the hopper 1 is facing the lower trough 3; the lower end of the vibrating frame 2 is equipped with some vibration devices; the present invention contacts the ground through the shock absorber 6.

[0016] The chute 3 is a slide with a certain bevel, and the preferred angle of the bevel is 10°-15°.

[0017] Described vibrating device comprises, vibration motor 8, supporting spring 5, electromagnetic plate 9, el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com