Pipe reeling machine

A tube reeling machine and tube reeling technology, which is applied in the directions of coiling strips, thin material processing, transportation and packaging, can solve the problems of complicated structure, high labor intensity and low efficiency of the tube reeling machine, and achieves simple structure and low energy consumption. The effect of labor intensity and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

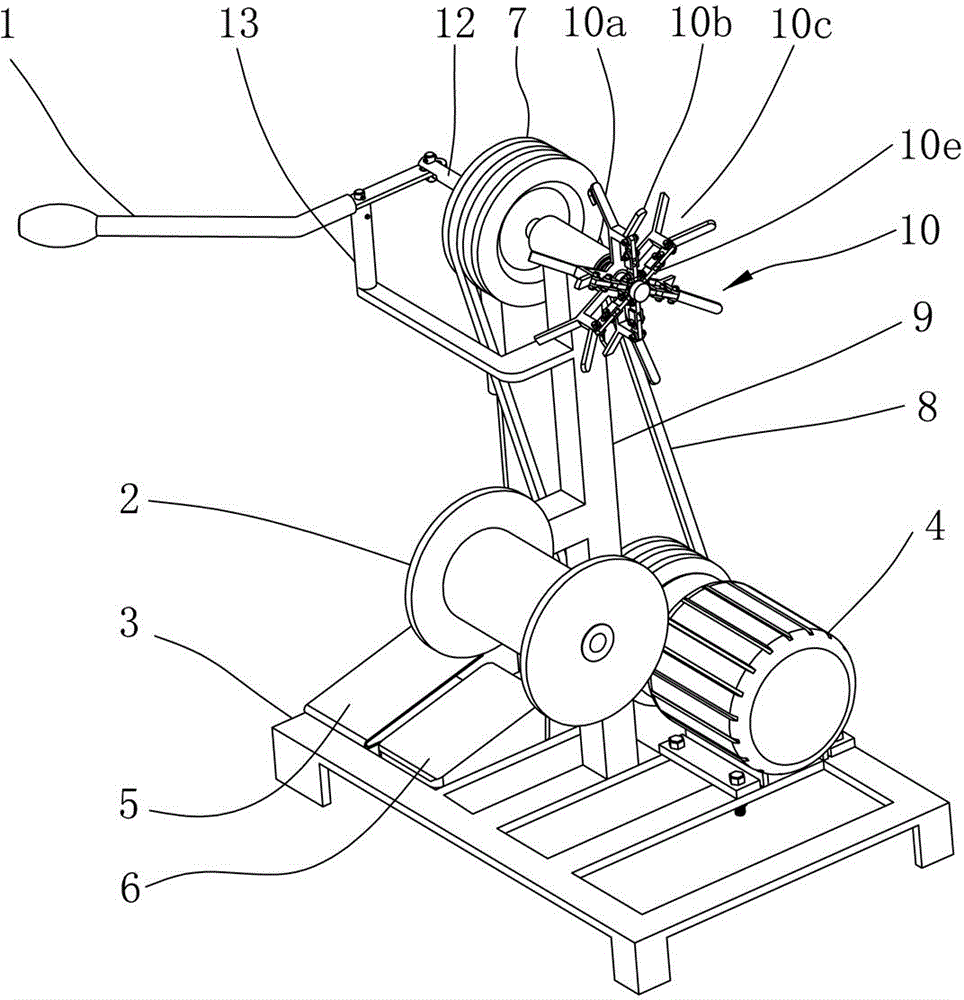

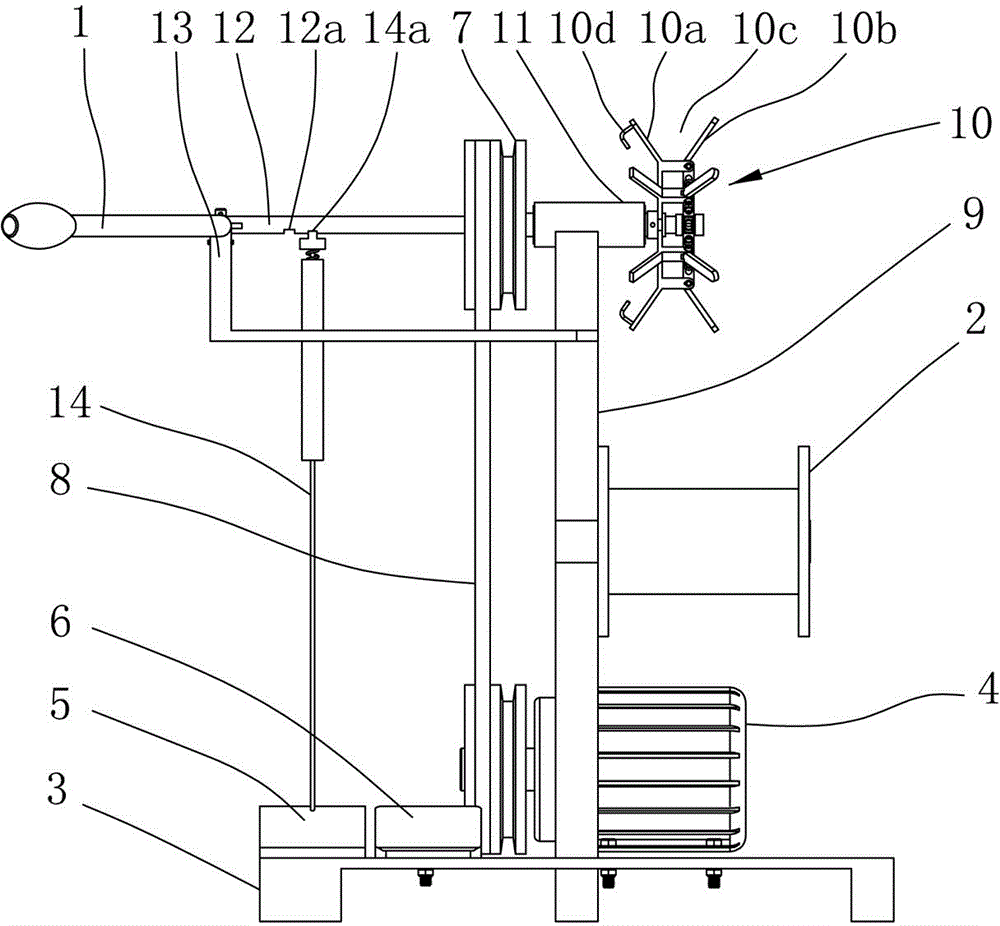

[0018] as attached figure 1 , attached figure 2 A hose reel shown includes a base 3, a bracket 9 mounted on the base 3, and a tube reel mechanism mounted on the bracket 9, and the reel mechanism is provided with a gripper 10 that can be opened and closed to curl the pipe And drive the driven wheel 7 that grabs 10 rotations, is provided with bearing seat 11 between described driven wheel 7 and grabs 10 and is connected; Described support 9 is provided with charging roller 2. Described driven wheel 7 is provided with belt 8 and is connected with a motor 4, and motor 4 drives driven wheel 7 to rotate, thereby makes driven wheel 7 drive catch disc 10 to rotate. The base 3 is provided with a foot switch 6 that can turn on the motor 4, which is convenient for the operator to operate and can start or stop the machine at any time.

[0019] As a preferred embodiment of the present invention, a gripper drive mechanism is also installed on the bracket 9, and the gripper drive mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com