Method for decolorizing and purifying paromomycin

A paromomycin and purification method technology, applied in chemical instruments and methods, preparation of sugar derivatives, sugar derivatives, etc., can solve the problems of cumbersome, complex production steps, low yield of paromomycin products, etc. The effect of improving product yield, saving production steps, and saving evaporation and concentration costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

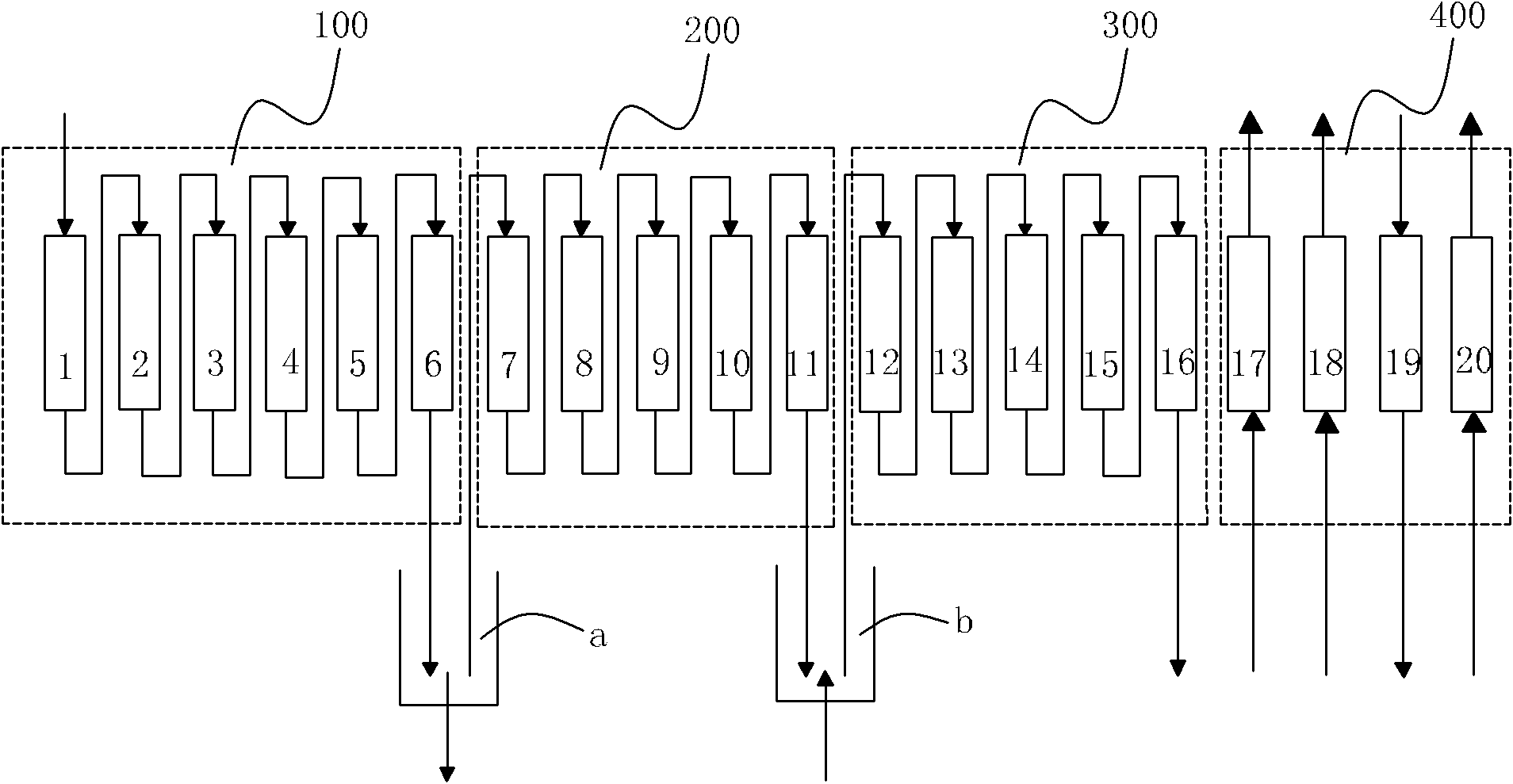

[0026] Such as figure 1 As shown in , the continuous moving bed rotating counterclockwise is equipped with 20 201×4 strong basic styrene-based anion exchange resin columns, which are divided into ammonia water analysis area 100, product separation area 200, and impurity separation area 300 in the clockwise direction. And resin regeneration area 200 four partitions, among them, No. 1~6 columns connected in series are ammonia water analysis area 100, No. 7~11 columns connected in series are product separation area 200, No. 12~16 columns connected in series The columns are the impurity separation area 300, the resin regeneration area 400 of the 17th to 20th column, and are successively set up as a water washing area, an alkali regeneration area, a water washing area and an acid regeneration area.

[0027] The inlet of the product separation zone 200 is set at the feed port at the upper end of the No. 7 resin column, and its outlet is set at the discharge port at the lower end of ...

Embodiment 2

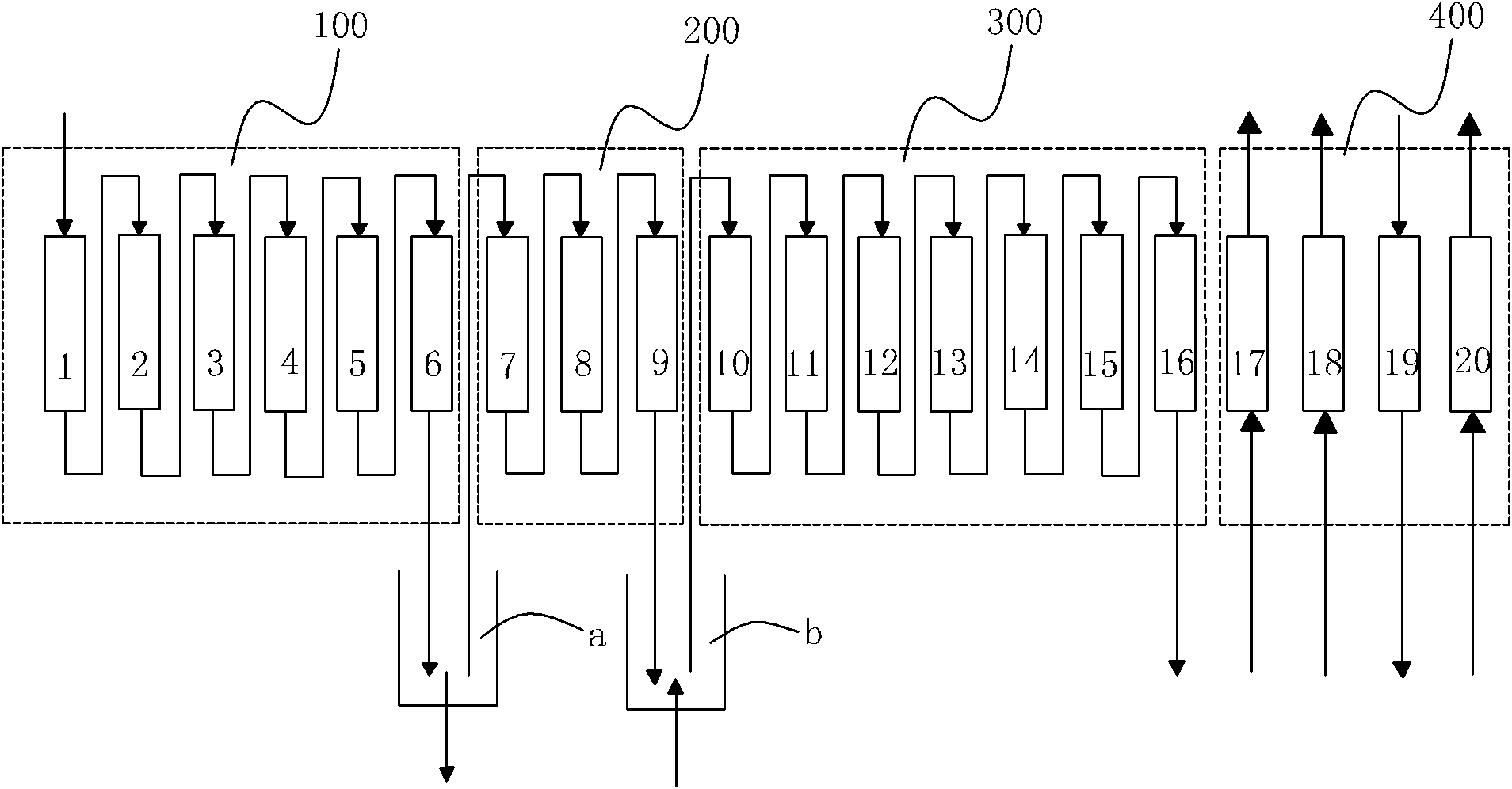

[0034] Such as figure 2 As shown in , the continuous moving bed rotating counterclockwise is equipped with 20 201×4 strong basic styrene-based anion exchange resin columns, which are divided into ammonia water analysis area 100, product separation area 200, and impurity separation area 300 in the clockwise direction. And resin regeneration area 200 four partitions, among them, No. 1~6 columns connected in series are ammonia water analysis area 100, No. 7~9 columns connected in series are product separation areas 200, No. 10~16 columns connected in series The columns are the impurity separation area 300, the resin regeneration area 400 of the 17th to 20th column, and are successively set up as a water washing area, an alkali regeneration area, a water washing area and an acid regeneration area.

[0035] The inlet of the product separation zone 200 is set at the feed port at the upper end of the No. 7 resin column, and its outlet is set at the discharge port at the lower end of...

Embodiment 3

[0042] Such as figure 1 As shown in , the continuous moving bed rotating counterclockwise is equipped with 20 201×4 strong basic styrene-based anion exchange resin columns, which are divided into ammonia water analysis area 100, product separation area 200, and impurity separation area 300 in the clockwise direction. And resin regeneration area 200 four partitions, among them, No. 1~6 columns connected in series are ammonia water analysis area 100, No. 7~11 columns connected in series are product separation area 200, No. 12~16 columns connected in series The columns are the impurity separation area 300, the resin regeneration area 400 of the 17th to 20th column, and are successively set up as a water washing area, an alkali regeneration area, a water washing area and an acid regeneration area.

[0043] The inlet of the product separation zone 200 is set at the feed port at the upper end of the No. 7 resin column, and its outlet is set at the discharge port at the lower end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com