Low gas permeable silicone resin composition and optoelectronic device

一种硅氧烷树脂、气体渗透性的技术,应用在电固体器件、半导体器件、半导体/固态器件零部件等方向,能够解决变色等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0106] Preparation of Silicone Resin Composition

[0107] The silicone resin composition can be prepared by simultaneously or sequentially stirring, dissolving, mixing and dispersing the above-mentioned components, if necessary, while heating. Most commonly, compositions are formulated and stored in two parts, one part including components (A), (B) and (C) and the other part including components (B) and (D), so that no curing reaction. In use, the two parts are mixed to allow the composition to cure. In particular, separate storage of components (C) and (D) is recommended because of potential dehydrogenation reactions of components (C) and (D) when stored together in the same part. The composition can be formulated in one portion if a small amount of a cure retardant such as acetylene alcohol is added.

[0108] The equipment used for stirring and mixing operations is not particularly limited, although a mixer equipped with stirring and heating facilities such as an automati...

Embodiment 1 to 5

[0138] The silicone resin composition was prepared by mixing the components prepared in Synthesis Examples 1 to 4 and 6 with the following components according to the formulation shown in Table 1.

[0139] (A') Vinyldimethylsiloxy-terminated phenylmethylpolysiloxane having the following general formula.

[0140] Phenyl content: 30wt%;

[0141] Vinyl equivalent: 0.0185mol / 100g

[0142]

[0143] where X=30 and Z=68.

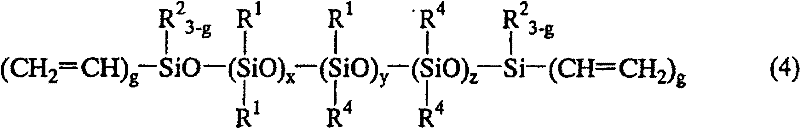

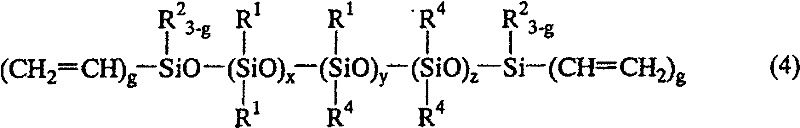

[0144] (B) Phenyl-containing branched methylhydrogen polysiloxane 2 having the following general formula.

[0145] Hydrogen release: 170.24ml / g (0.760mol / 100g)

[0146]

[0147] (C) Platinum catalyst: octyl alcohol-modified solution of chloroplatinic acid (Pt concentration: 2 wt%).

PUM

| Property | Measurement | Unit |

|---|---|---|

| release amount | aaaaa | aaaaa |

| Weight-average Molecular Weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com