Anti-graffiti coatings

A coating, methyl technology, used in the preparation of coating compositions and coatings, which can solve problems such as staining or marking, permanent damage to painted surfaces, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0054] The present invention also provides a method of preparing a coating comprising applying a coating composition to a substrate and allowing the coating to harden (for example by exposing the coating composition to radiation such as ultraviolet or visible light). The present invention also provides coatings prepared or producible from the coating compositions described herein. For example, coatings of the invention can be prepared by a process comprising applying the coating composition to a substrate and allowing the coating composition to harden (eg, by exposing the coating composition to radiation such as ultraviolet or visible light).

[0055] A preferred coating is obtained by exposing the coating to a -3 nm to 800nm radiation to cure. More preferably, the coating composition of the present invention is exposed to ultraviolet or visible light in the range of 200nm to 800nm. The coating compositions of the present invention may also be cured thermally or by other f...

Embodiment 1

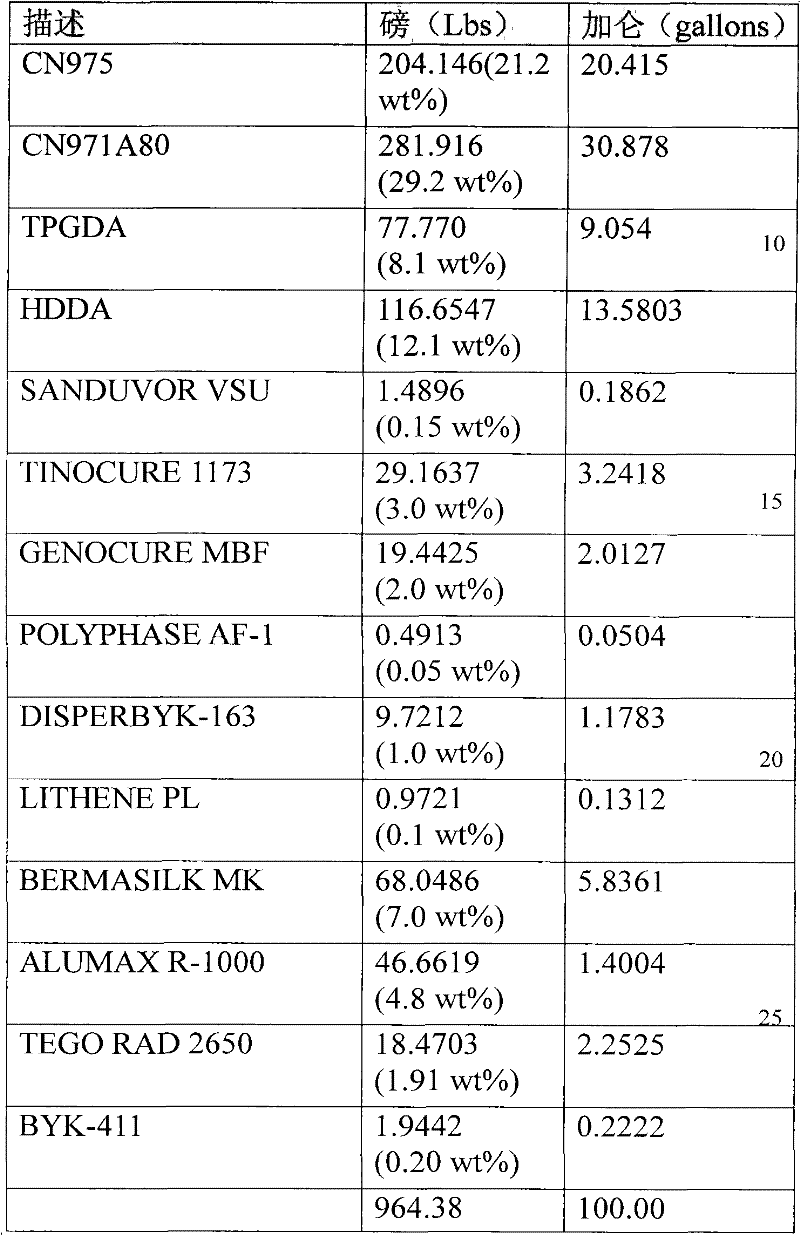

[0087] Embodiment 1: Preparation of urethane coating composition

[0088] The metal particles and matting agents listed in Table 1 below were dispersed in a mixer / disperser such as those available from Morehouse Cowles, Chino, CA or from Hockmeyer Equipment Corp., Elizabeth City, NC. The remaining ingredients are then dispersed in a mixer to form a coating composition.

[0089] Table 1

[0090]

[0091] The coating composition was rolled onto wood floor samples and then cured with UV light to form the coating.

[0092] After curing was complete, the coating was marked with a permanent marker available from Sanford LP, Oak Brook, IL under the trade name Sharpie. After the ink from the marker has dried, wipe the marker with a white cotton rag. Start by rubbing lightly and then more vigorously to assess whether the ink can be removed completely without affecting the gloss of the coating or removing the coating. If the shading or dye remains after wiping with a cotton cloth...

Embodiment 2

[0094] The preparation of embodiment 2-epoxy resin coating composition

[0095] Using the procedure set forth in Example 1 above, an epoxy coating composition was prepared using the ingredients in Table 2 below.

[0096] After curing was complete, the coating was marked with a permanent marker available from Sanford LP, Oak Brook, IL under the trade name Sharpie. After the ink from the marker dries, wipe the marker with a white cotton rag. Start by rubbing lightly and then more vigorously to assess whether the ink can be removed completely without affecting the gloss of the coating or removing the coating. If the shading or dye remains after wiping with a cotton cloth, use rubbing alcohol and / or nail polish remover to remove any remaining markings.

[0097] The ink marks can all be completely removed with the coating still intact.

[0098] Table 2

[0099] type

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com