Planting bar grouting and anchoring construction process for antique stone balustrade

A construction technology and railing technology, applied in the direction of bridge reinforcement, bridge parts, erection/assembly of bridges, etc., can solve problems such as man-made damage, weak foundation, loosening, falling off, etc., to solve stability problems, ensure safety and stability good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] (1) Planting bar embedding method

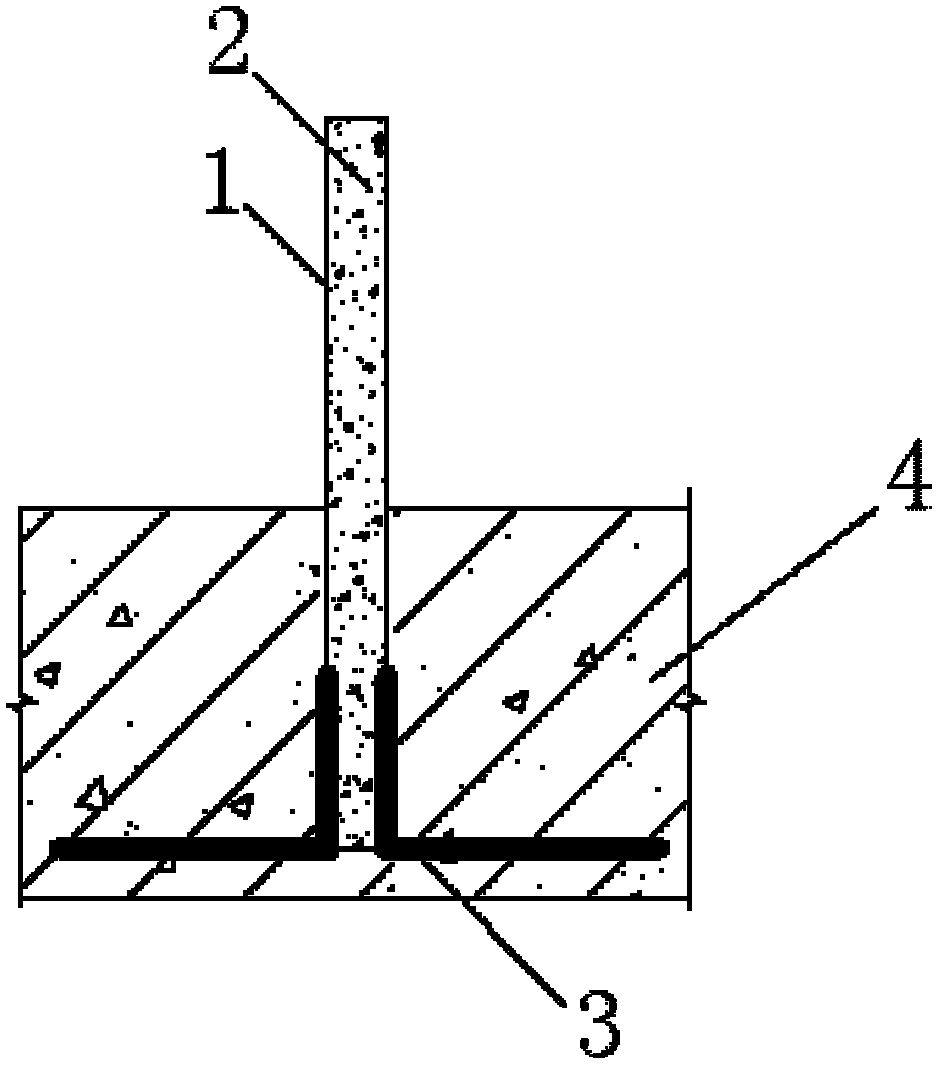

[0020] The setting method in the new project: such as figure 1 As shown, during the construction of the main body, a φ45 galvanized steel pipe 1 is pre-embedded at the center of the concrete beam 4 where the railing column 6 is to be installed. The steel tenons of the railing column 6 are used, and the center position and verticality of the buried galvanized steel pipe 1 are strictly controlled when setting.

[0021] Such as figure 1 As shown, in order to ensure the firmness of the galvanized steel pipe 1 in the concrete beam, the bottom of the galvanized steel pipe 1 is fixed by welding an "L" shaped anchor bar 3 .

[0022] (2) 6 drill holes for stone railing posts

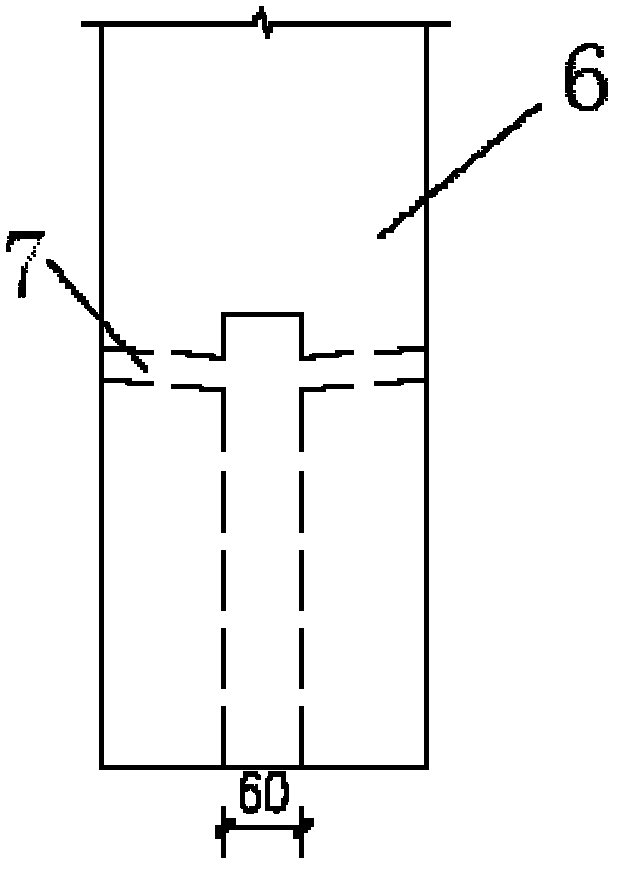

[0023] Such as image 3 As shown, at the center position of the bottom of the railing column 6, a circular hole with a diameter of φ60 is drilled, and the depth of the circular hole is 350 mm. Then, grouting holes 7 are opened on both sides of the railing installatio...

Embodiment 2

[0028] (1) Planting bar embedding method

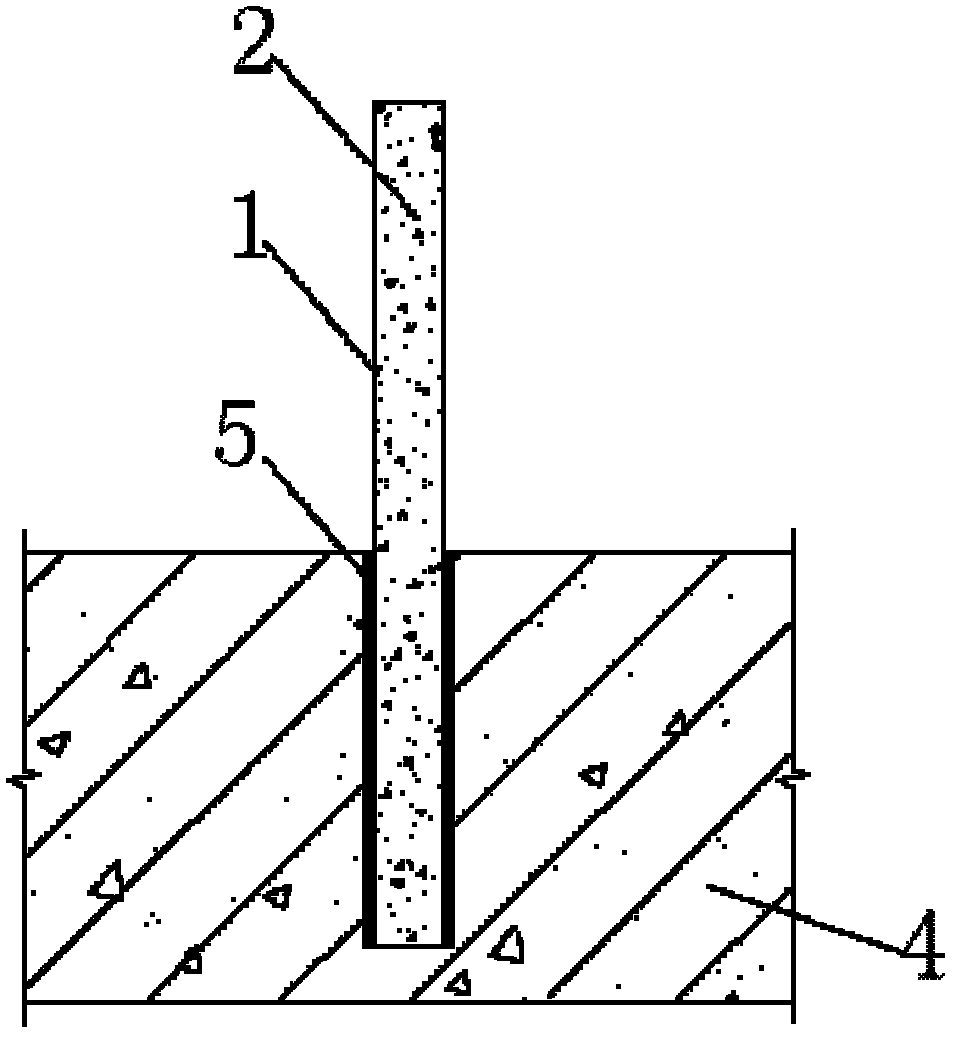

[0029] Setting method in the construction project: For construction projects, there is a concrete beam 4 under the general railing installation position, and a 250mm deep φ60 round hole can be directly drilled at the center of the railing installation. After the hole is cleaned with high-pressure gas, it can be directly used The prepared HGM series high-strength non-shrinkage grouting material 5 is enough to fix the φ45 galvanized steel pipe 1 on the concrete beam 4, and strictly control the center position and verticality of the buried steel pipe 1 during installation. The structure is as follows figure 2 shown.

[0030] All the other (2), (3), (4) steps are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com