High-stability assembled bridge based on steel structure

A high stability, steel structure technology, applied in bridges, bridge construction, bridge parts, etc., can solve the problems of no connection structure, lack of bridge damping device, general connection effect, etc., to increase the shock absorption effect and increase the versatility , The effect of convenient assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

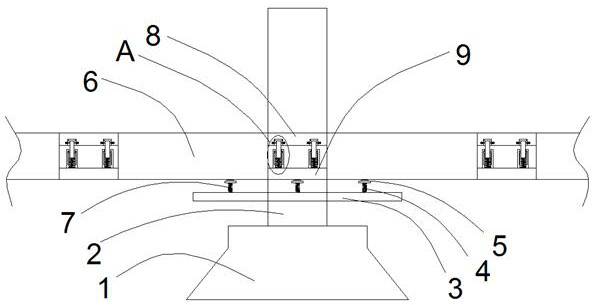

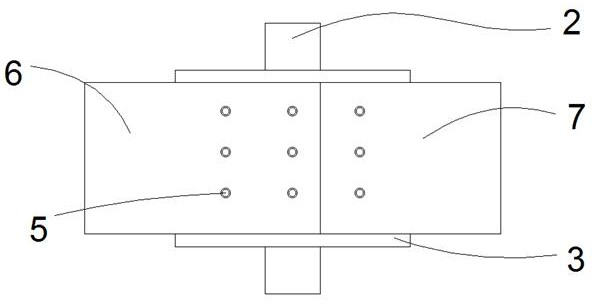

[0033] Please refer to Figure 1 to Figure 4, in the first embodiment of the present invention, the high-stability assembled bridge based on steel structure includes: pier 1; Universality and high stability, there is no contact between the two sides of the bridge frame 2 and the two sides of the bridge 6, and the bridge 6 is only supported by springs, which can achieve a greater degree of shock absorption. At the same time, the gap distance between the bridge 6 and the bridge frame 2 It can be used as the maximum swing range to monitor the load range of the bridge 6. The third fixed plate 24 is fixedly installed on the top beam of the bridge frame 2; the first support plate 3 is fixedly installed on the inner bottom surface of the bridge frame 2, and the first The length of the support plate 3 is consistent with the length of the bridge 6, and the center of symmetry coincides with the center of symmetry of the second support plate 8 and the third support plate 9. This design c...

no. 2 example

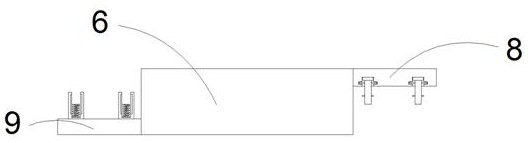

[0041] Based on the high-stability assembled bridge based on the steel structure provided by the first embodiment of the present application, because when using this device, the springs everywhere can only solve the vertical direction damping effect between the bridges 6, and the bridges 6 Stability and buffering in the horizontal direction are also factors that must be considered in the construction of the bridge 6. In order to further improve the stability of the steel structure assembled bridge and avoid the impact of the load force in the horizontal direction on the stability of the bridge 6, please refer to Figure 5-7 , in the second embodiment of the present invention, the high-stability assembled bridge based on the steel structure also includes: a power supply block 17, the bottom of the second support plate 8 is fixed and rotated with a power supply block 17, as the name suggests, the power supply block 17 is mainly a power supply device , which can flow forward and r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com