Hydraulic ship-lifting system

A water conservancy and ship compartment technology, applied in the direction of vertical lifting of ship machinery, ship locks, ship lifting devices, etc., can solve the problems of small dam crossing capacity, accidents or insufficient maintenance capacity, etc., achieve controllable water level rise and fall speed, and shorten running time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

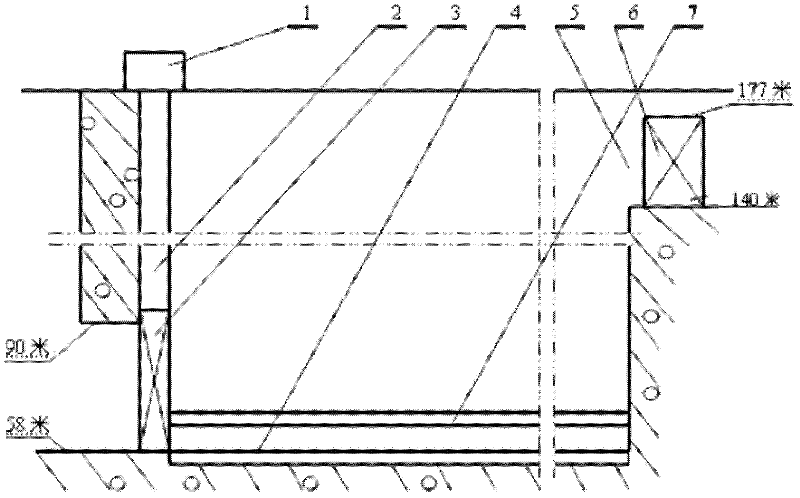

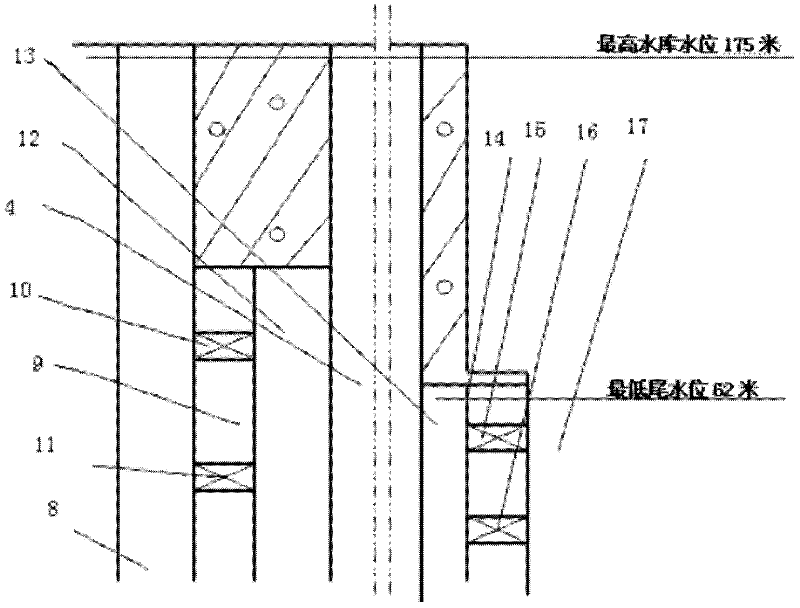

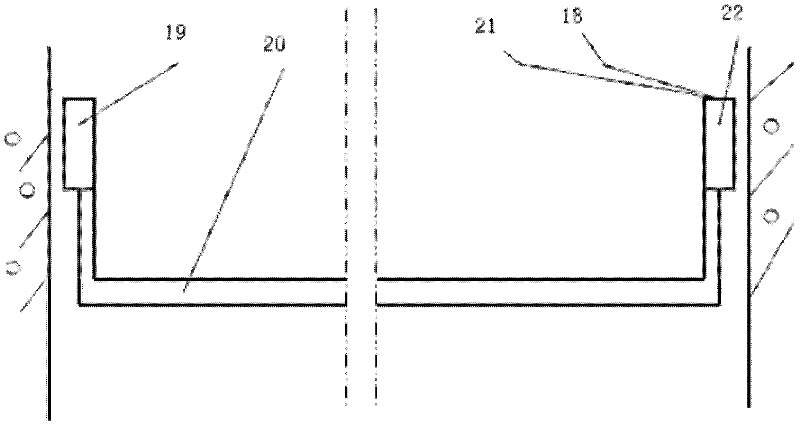

[0024] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0025] see Figure 1-4 , a water conservancy ship lift system, which includes a deep well type lock chamber 4, a lower lock head 2 is arranged at the lower part of one end of the lock chamber, a gate 3 is arranged inside the lower lock head, a hoist 1 is arranged on the top of the gate, and the other end of the lock chamber The upper part of the upper lock head is provided with an upper lock head 5, and the upper lock head is provided with a miter door 6, and the lock chamber is provided with a lock chamber water filling and drainage system, and the lock chamber is provided with a floating ship compartment 7, and the lock chamber is filled with water and drained The system includes an upstream water supply pool 8, which is connected to a water filling valve chamber 9. The water filling valve chamber is equipped with a first spherical valve group 10 and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com