Positive-pressure blasting device

A technology of detonation and pressure, which is applied in the field of oil and gas exploration, and can solve the problems that high-energy gas fracturing without casing in ultra-shallow wells cannot be realized

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

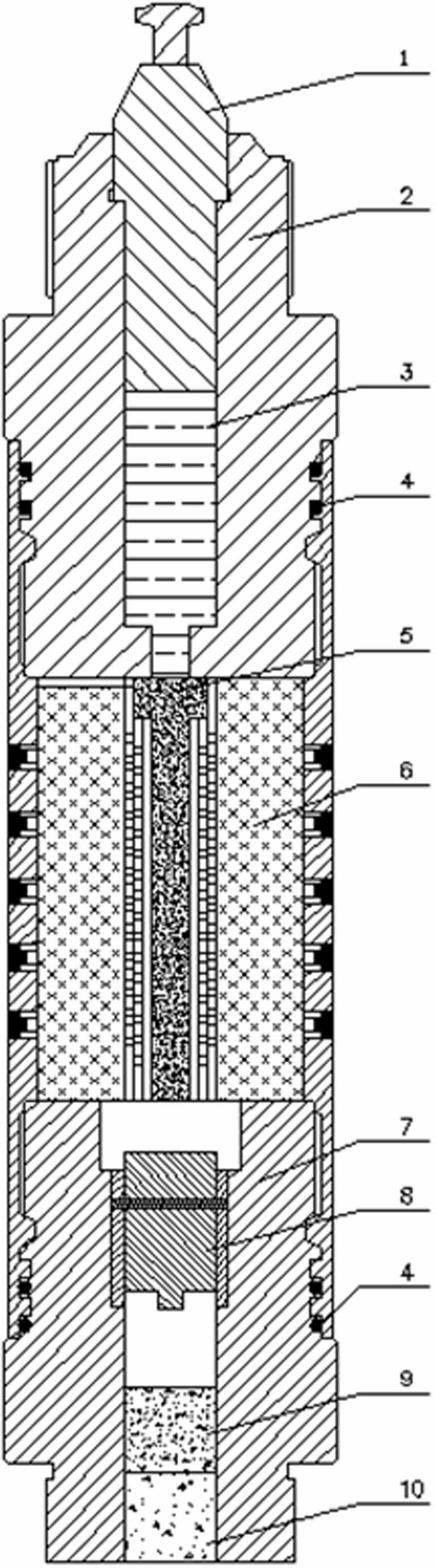

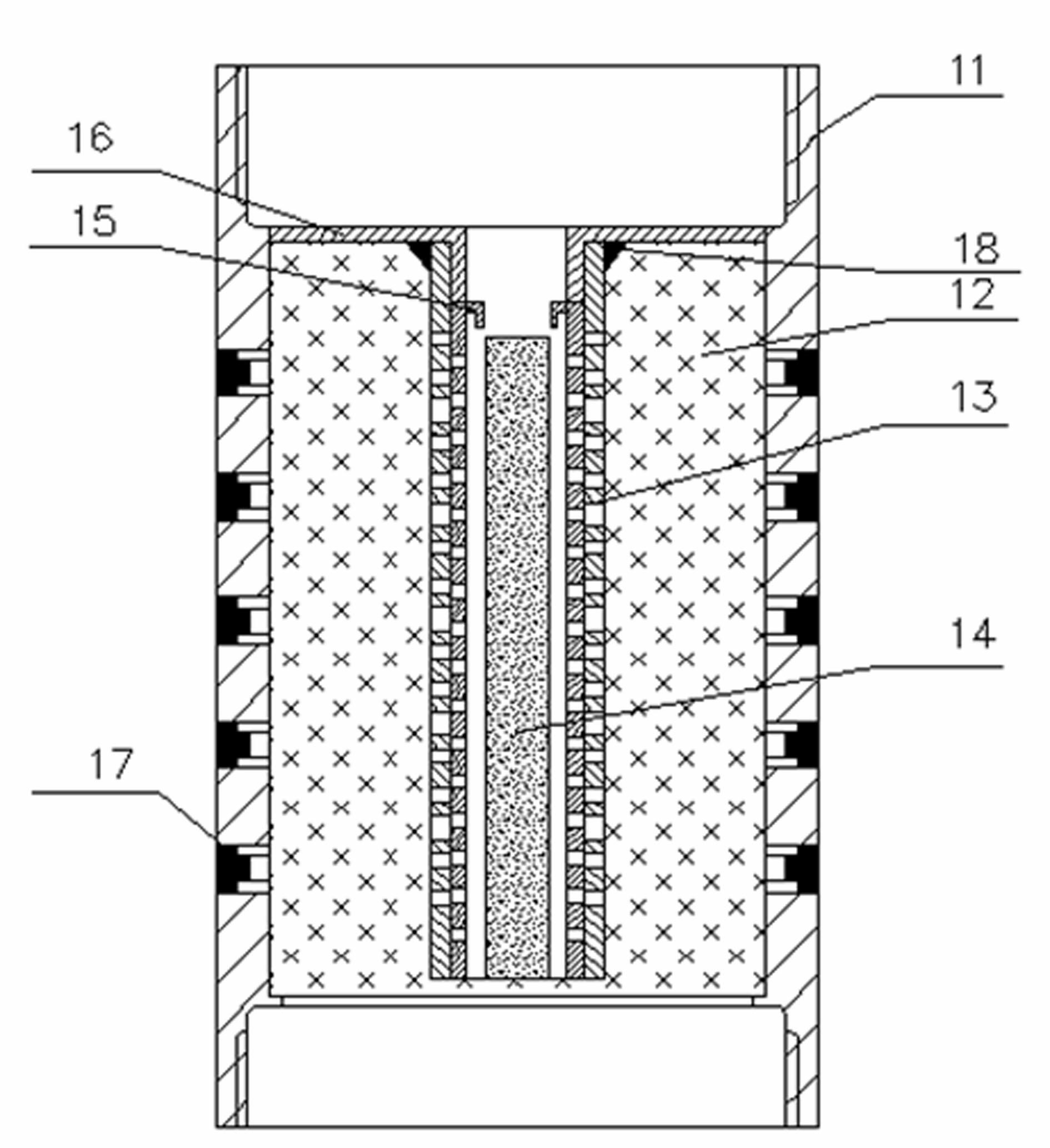

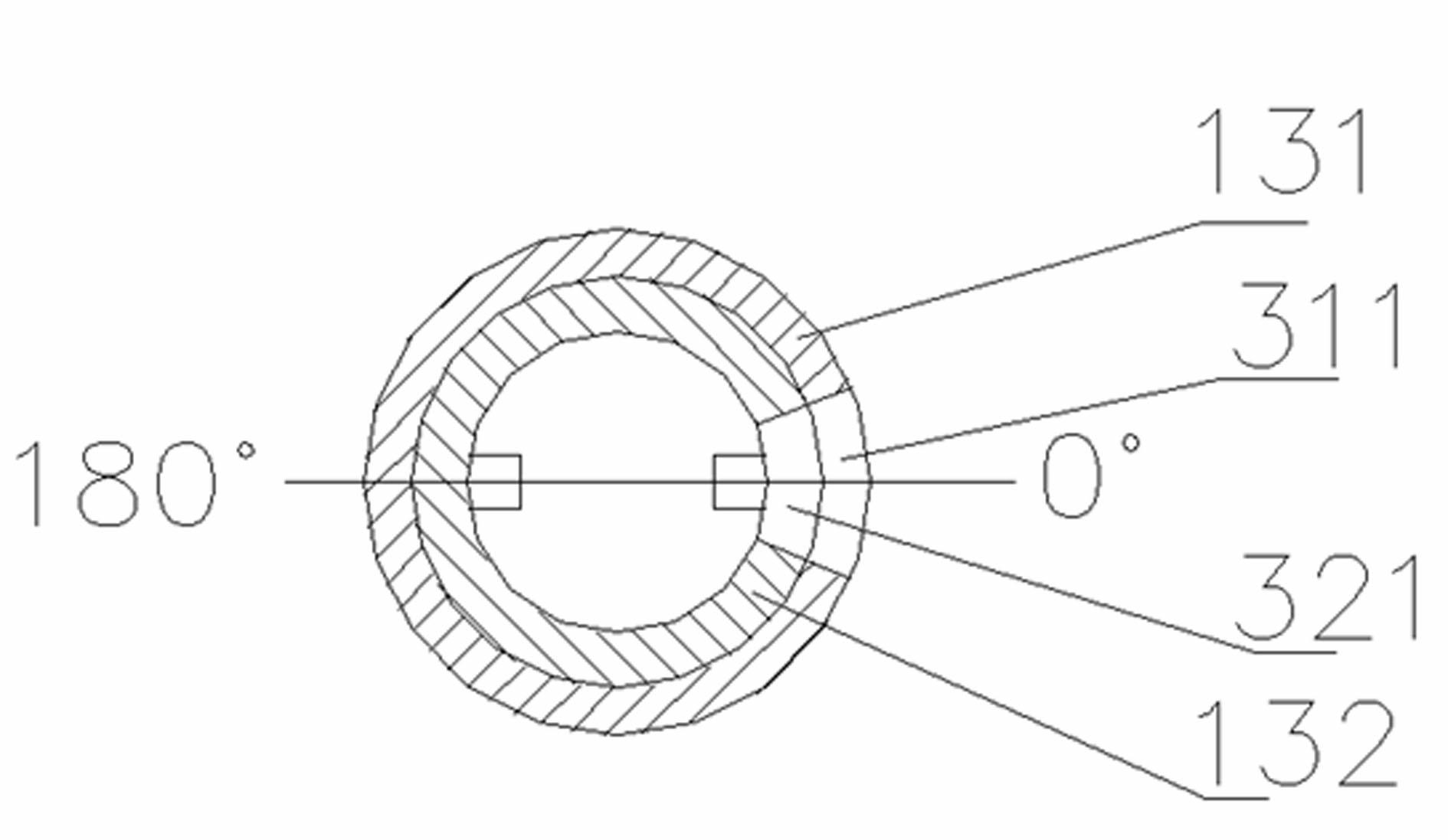

[0011] like figure 1 As shown, a positive pressure detonation device includes a percussion ignition system. The percussion ignition system includes a percussion firing needle 1, a percussion ignition joint 2, and an ignition core 3. The ignition core 3 and the percussion core are housed in the center hole of the percussion ignition joint 2. The firing pin 1, the ignition joint 2 impacts the firing pin and is connected with the screw, the impact firing pin 1 squeezes and fixes the firing core 3, and the sealing groove of the firing joint 2 is covered with an O-ring 4; it also includes Pressure generator, detonating device, the center hole of pressure generator 6 is provided with a bridge plug charge 5, the upper end of pressure generator 6 is screwed and connected with firing joint 2; the detonating device includes pressure detonating joint 7, pressure detonating firing pin 8, micro The detonating core 9, the booster charge 10, the center of the pressure initiation joint 7 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com