Shield tunneling prestress lining construction method and used prestressed pipe pieces

A technology of shield tunnel and construction method, which is applied to tunnel lining, tunnel, shaft lining and other directions, can solve the problems of difficult removal of air bubbles on the concrete surface, poor concrete pouring, and difficulty in meeting requirements, etc., and achieves simple and fast construction operations and reduces construction costs. The effect of short cost and working time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

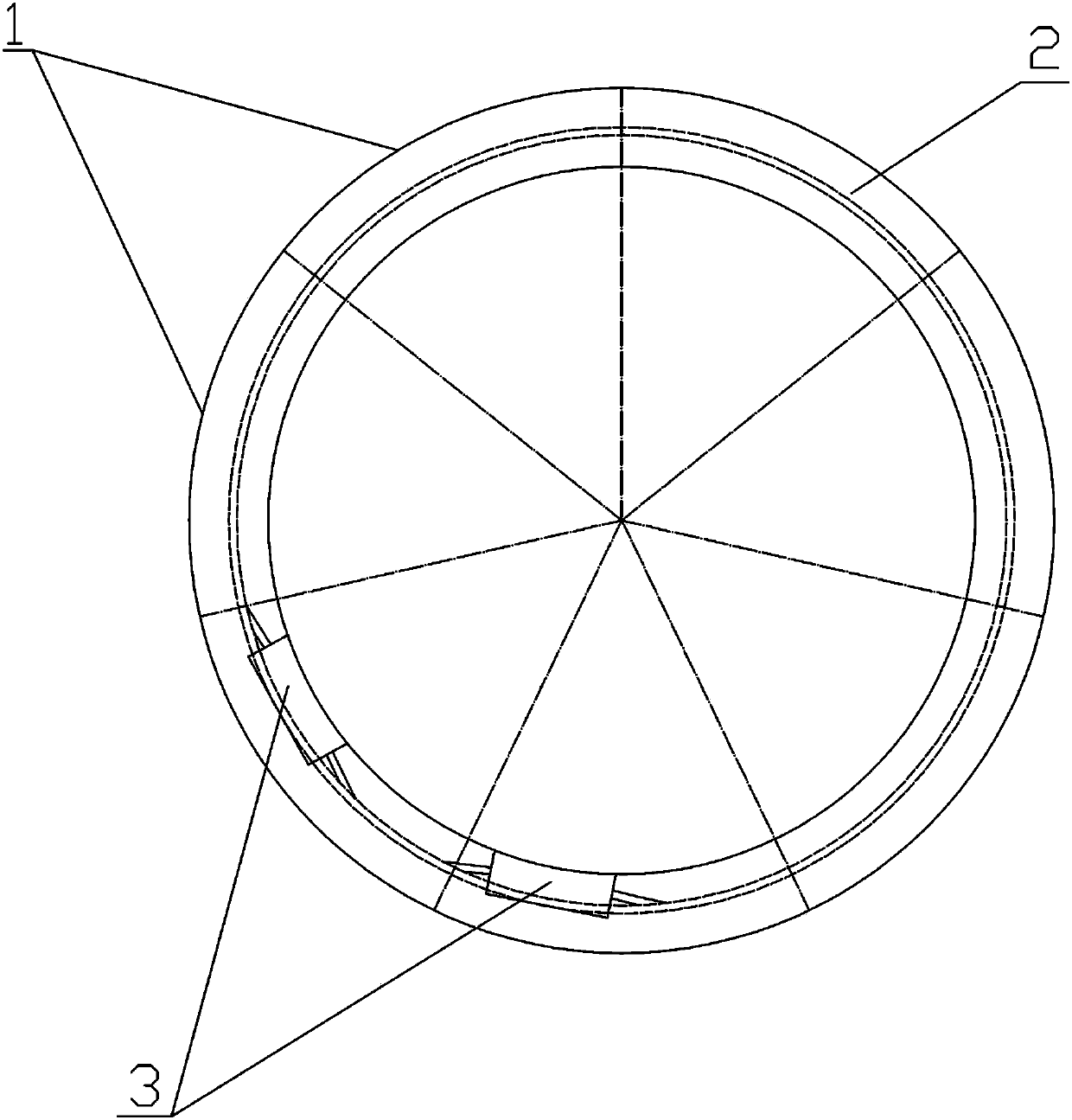

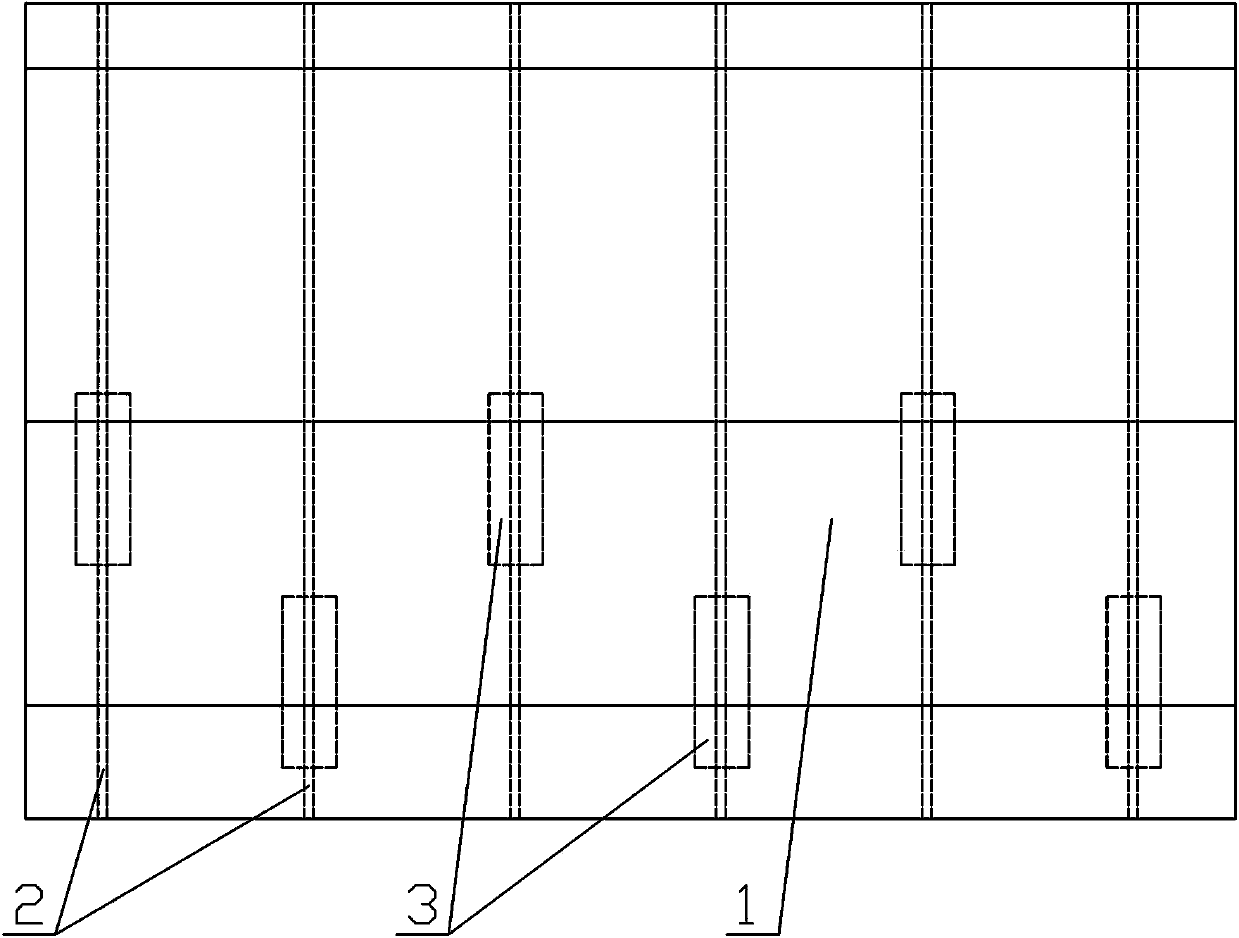

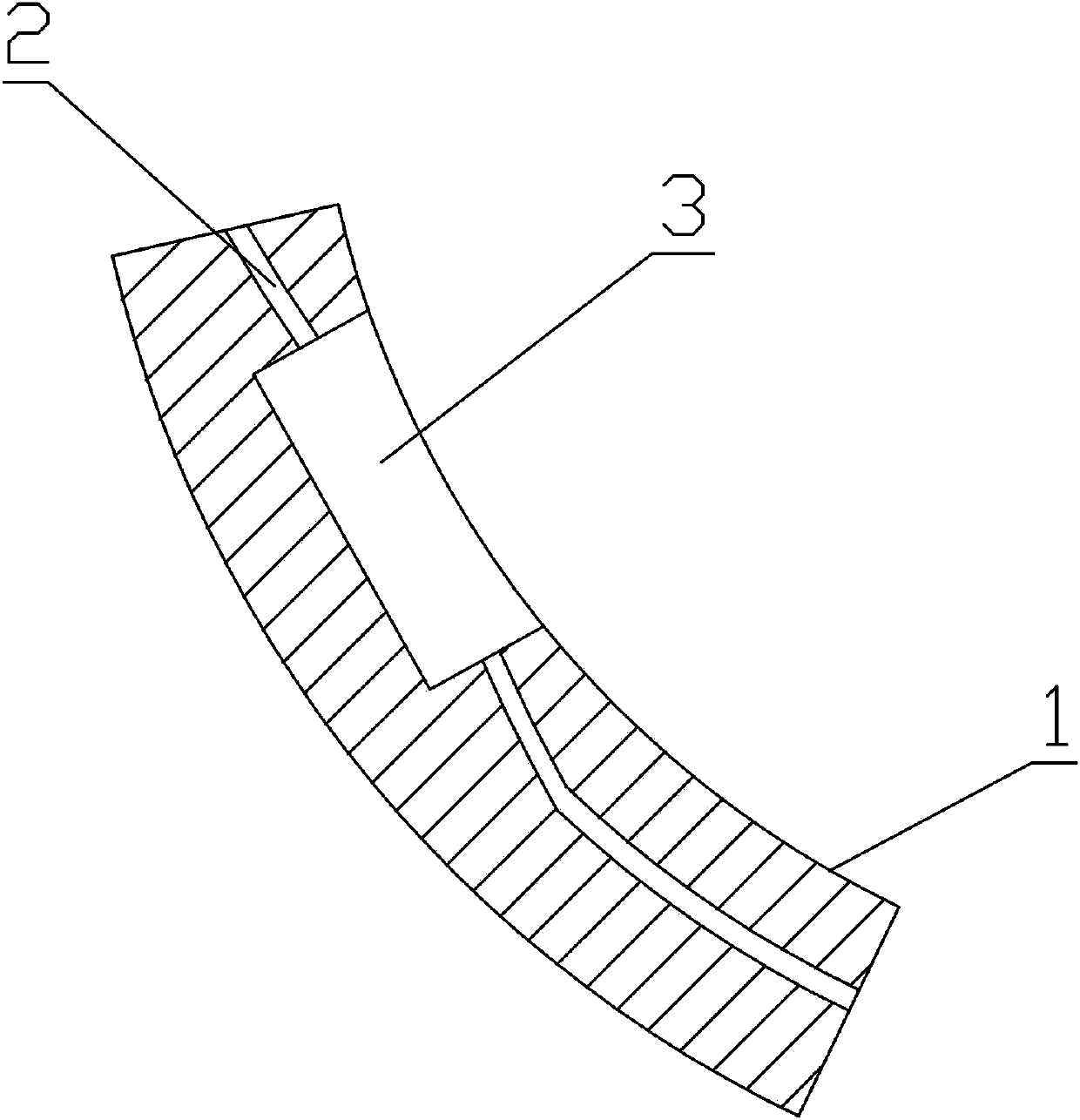

[0030] A prestressed segment, the segment 1 is provided with a plurality of steel strand channels 2 distributed along the axis, and on the circumference formed by the plurality of segment 1, the corresponding steel strand channels 2 communicate with each other, each steel strand An anchor groove 3 is provided on the stranded wire channel 2 .

[0031] The anchor grooves 3 are staggered on the circumference.

[0032] The anchor groove 3 opens to the inner side of the circumference.

[0033] A method for constructing prestressed lining of a shield tunnel by using the above prestressed segments, comprising the following steps:

[0034] 1. The steps of segment assembly for shield tunneling;

[0035] (1) Assemble the standard segment and the connecting segment symmetrically from the bottom of the shield tunnel upwards, the steel strand tunnel is positioned accurately, and there is no wrong connection.

[0036] (2) Arrange the segments with reserved anchorage grooves staggeredly i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com