Progressive yielding combined-type extensible anchor rod and construction method thereof

A composite, bolting technology, applied in the installation of bolts, earth-moving drilling, mining equipment, etc., can solve the problems of anchoring, breaking, and difficulty in exerting the self-supporting ability of surrounding rock.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

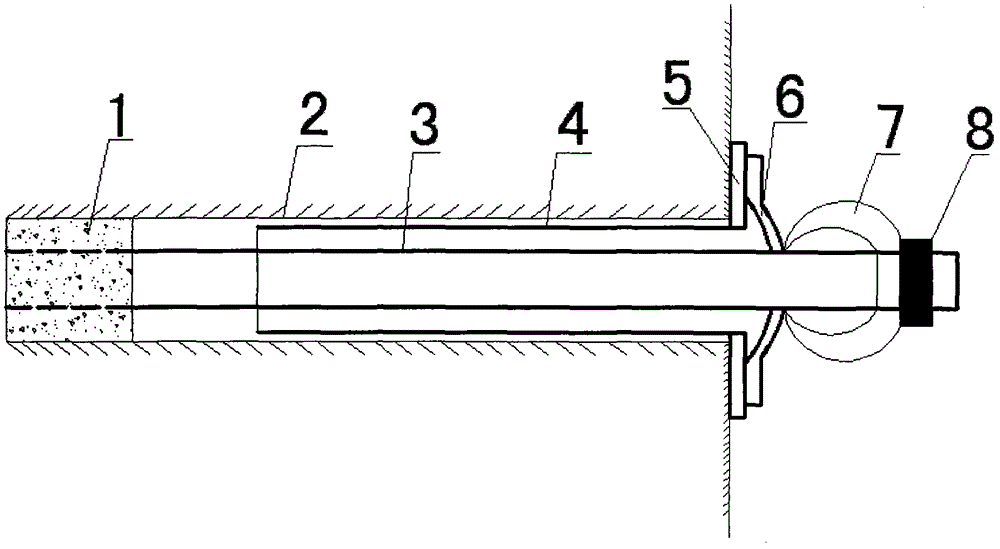

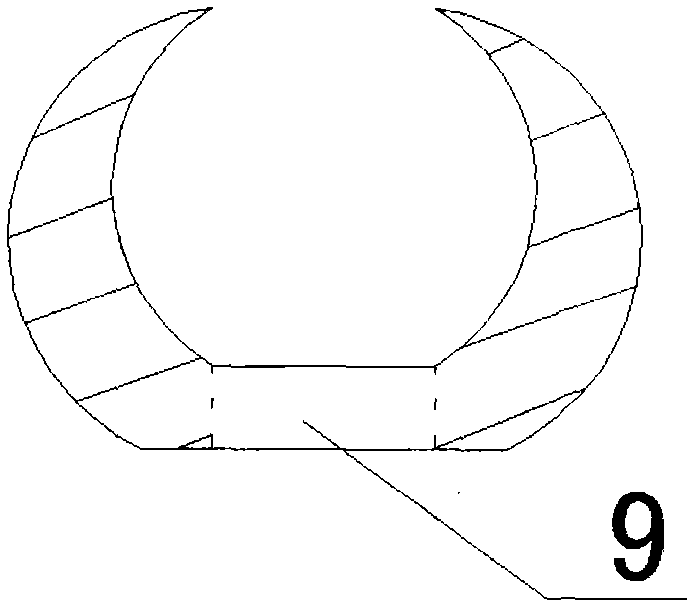

[0025] like figure 1 As shown, the progressive pressure-releasing compound type extensible anchor rod structure of the present invention is: it comprises the pipe-seam type anchor rod and the threaded steel resin anchor rod installed in the anchor hole; The above-mentioned threaded steel resin anchor is composed of resin anchoring end 1, threaded steel resin anchor body 3, pressure tray 6 and nut 8; wherein, the length of the threaded steel resin anchor It is longer than the length of the pipe seam anchor rod, and the threaded steel resin anchor rod body passes through the pipe seam type anchor rod body, and a progressive pressure relief part 7 is provided between the pressure relief tray 6 and the nut 8 of the threaded steel resin anchor rod; The progressive pressure member 7 is a steel ball shell, the steel ball shell has a croissant cross-sectional shape, and the bottom surface is provided with a through hole 9 passing through the threaded steel resin anchor rod body 3.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com