Multi-multiple-arch rectangular tunnel arch-dividing construction method

A construction method and tunnel technology, applied in artificial islands, water conservancy projects, infrastructure projects, etc., can solve the problems of easy occurrence of cold joints, long interval time between cement tankers, and large amount of concrete pouring, so as to reduce cold joints and backfill pressure. The effect of easy control of solidity and small amount of backfill

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

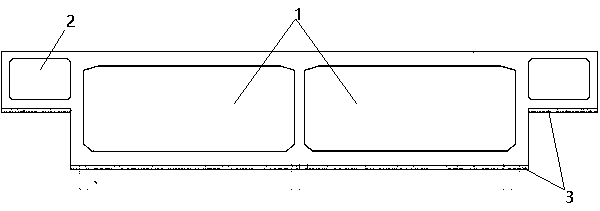

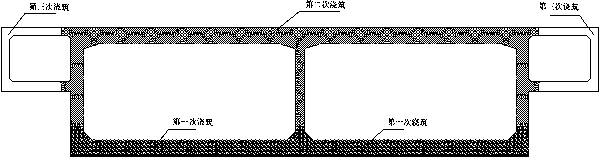

[0032] Such as Figure 1 to Figure 3 shown, including the following steps:

[0033] Step 1: Divide the multi-arch tunnel into arches according to motor vehicle tunnel 1 and non-motor vehicle tunnel 2;

[0034] Step 2: Construction of support piles and water-stop curtains;

[0035] Step 3: Excavation of the foundation pit, first excavated to 20cm below the upper floor of the non-motor vehicle tunnel 2;

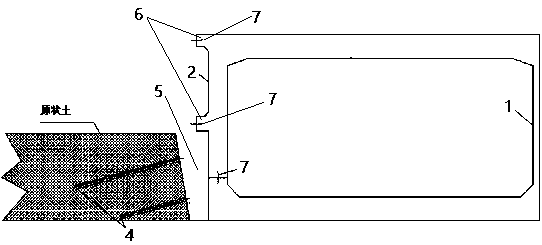

[0036] Step 4: Keep the undisturbed soil of the non-motor vehicle tunnel 1 sub-arch, continue the foundation pit of the motor vehicle tunnel 1 part to 20cm below the upper floor of the floor, and reserve the excavation between the motor vehicle tunnel 1 and the non-motor vehicle tunnel 1 sub-arch undisturbed soil Fertilizer trough 5, grading and construction soil nail 4 on the side of undisturbed soil;

[0037] Step 5: laying cement cushion 3;

[0038] Step 6: Construction of motor vehicle tunnel 1 floor reinforcement and formwork, and completion of concrete pouring;

[00...

Embodiment 2

[0046] Step 1: Divide the multi-arch tunnel into arches according to motor vehicle tunnel 1 and non-motor vehicle tunnel 2;

[0047] Step 2: Construction of support piles and water-stop curtains;

[0048] Step 3: Excavation of the foundation pit, first excavated to 20cm below the upper floor of the non-motor vehicle tunnel 2;

[0049] Step 4: Keep the undisturbed soil of the non-motor vehicle tunnel 1 sub-arch, continue the foundation pit of the motor vehicle tunnel 1 part to 20cm below the upper floor of the floor, and reserve the excavation between the motor vehicle tunnel 1 and the non-motor vehicle tunnel 1 sub-arch undisturbed soil Fertilizer trough 5, grading and construction soil nail 4 on the side of undisturbed soil;

[0050] Step 5: laying cement cushion 3;

[0051] Step 6: Construction of motor vehicle tunnel 1 floor reinforcement and formwork, and completion of concrete pouring;

[0052] Step 7: set up the support and construct the roof of the motor vehicle tunn...

Embodiment 3

[0056] In this embodiment, the side slope ratio of the undisturbed soil in step 4 is 1:0.5. Grading while excavating the foundation pit of the first part of the motor vehicle tunnel. Soil nail 4 is constructed according to the specification.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com