Double-layer molded composite lining for weak surrounding rock tunnel

A composite technology with weak surrounding rock, applied in the direction of tunnel lining, tunnel, shaft lining, etc., can solve the problems of material waste, large amount of rebound, construction difficulties, etc., and achieve the goal of reducing material loss, avoiding material waste, and reducing construction costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

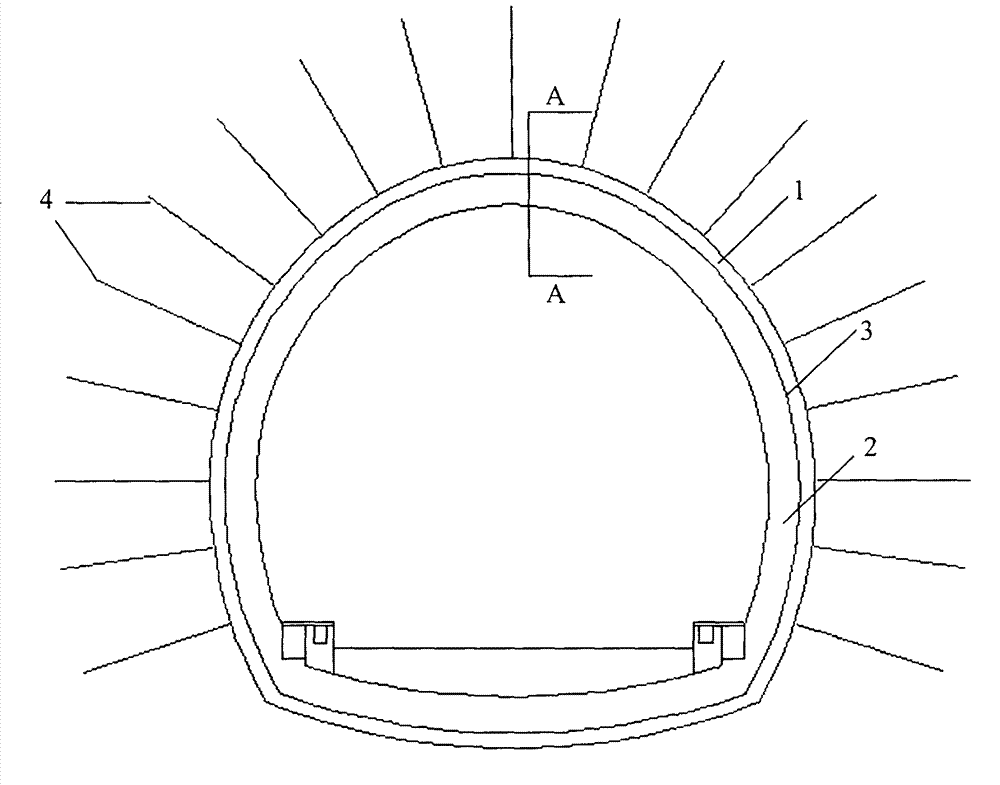

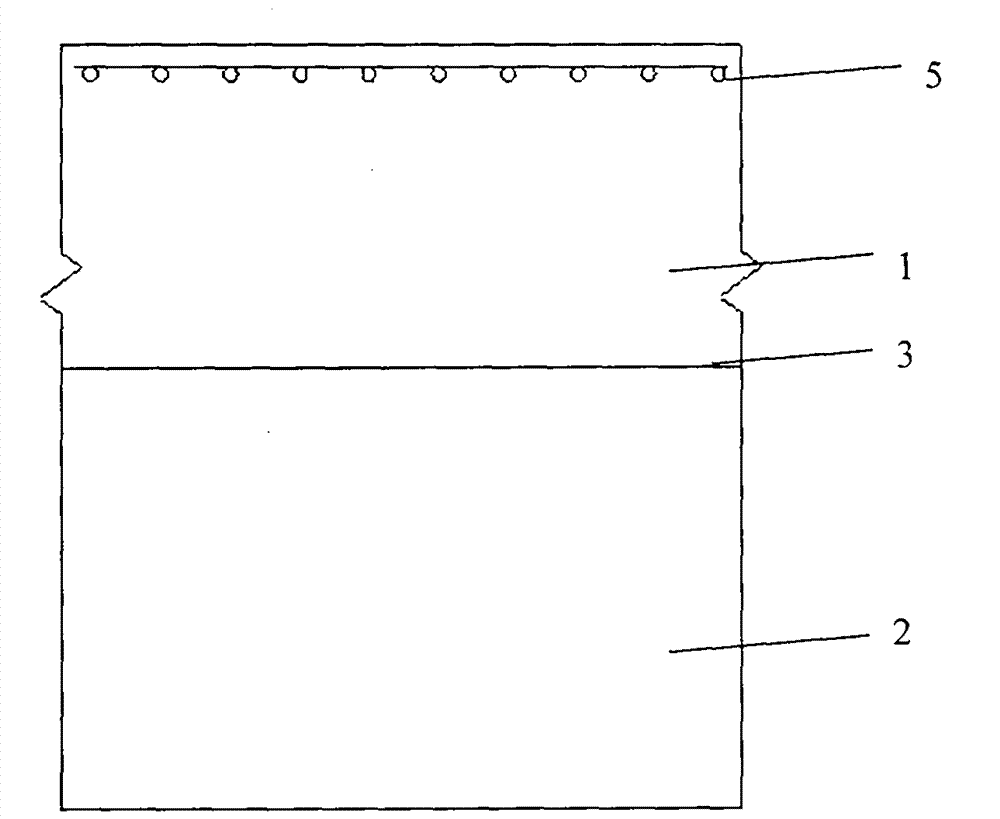

[0031] The present invention changes the composite lining support form (anchor rod, steel mesh, shotcrete + secondary molded concrete composite lining) into a double-layer molded composite lining support form (anchor Rods, steel mesh, primary molded concrete + secondary molded concrete composite lining), the primary support system is changed from flexible support to rigid support, that is, shotcrete is canceled and replaced by primary molded concrete.

[0032] see figure 1 and figure 2 , in this embodiment, including the initial molded concrete layer 1, the secondary molded concrete layer 2, and the waterproof layer 3, it is characterized in that: after the excavation of the surrounding rock of the tunnel, an anchor rod 4, a steel mesh 5, and an initial molded concrete layer are respectively provided. Concrete layer 1 and other primary support systems; the primary molded concrete layer 1 is provided with a secondary molded concrete layer 2; a waterproof layer 3 is provided b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com