Shock-absorbing bearing component for belt wheel of automobile engine

A technology for automobile engines and bearing components, which is applied to bearing components, rotating bearings, rigid supports of bearing components, etc. It can solve the problems of local stress concentration of the shock absorber ring, affecting the bearing life, difficult to install in place, etc. The effect of force distribution, extended service life, and easy and correct assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

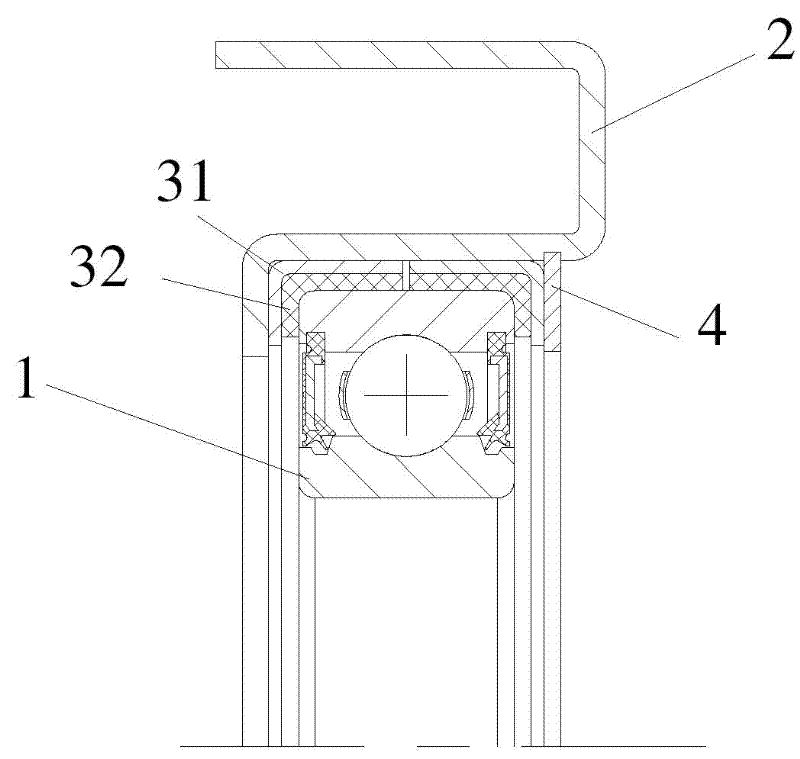

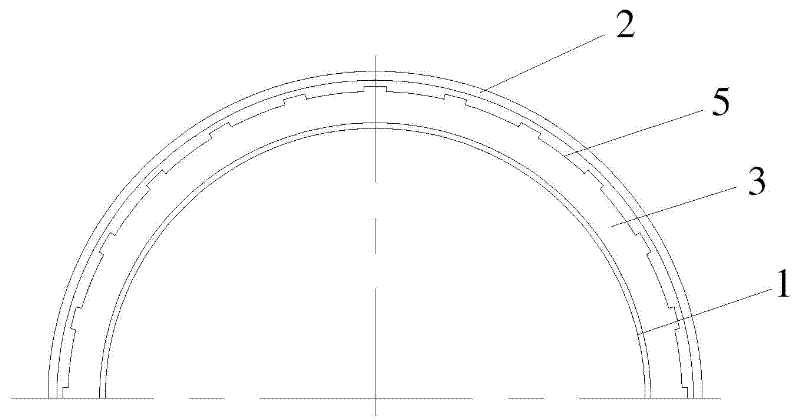

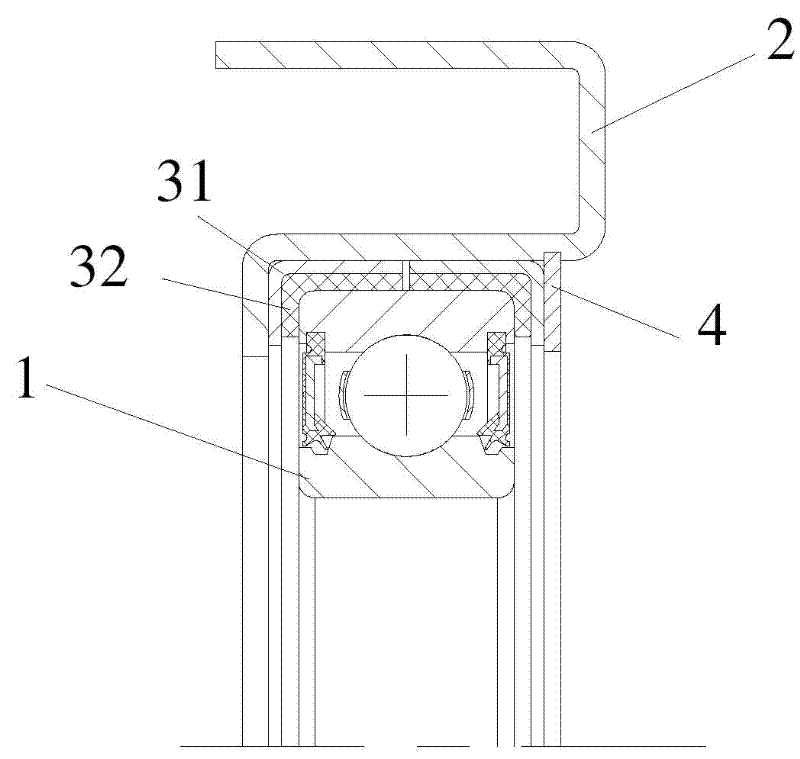

[0013] Such as figure 1 and figure 2 Shown: a shock-absorbing bearing assembly for an automobile engine pulley, the bearing 1 is in contact with the pulley 2, the outer ring of the bearing 1 is covered with a hollow cylindrical shock-absorbing pad 3, and the shock-absorbing pad 3 has two , they are respectively arranged at the two ends of the outer ring of the bearing 1, and include an outer metal skeleton 31 and an inner elastic material 32, and it also includes a belt between the outer edge of the end face of the bearing 1 and the pulley 2 to define the The hole of the shock-absorbing pad 3 positions uses the retaining ring 4.

[0014] In the shock-absorbing bearing assembly for the pulley of the automobile engine, the shock-absorbing pad 3 is provided with an inward flange to buckle the end surface of the outer ring of the bearing 1 .

[0015] In the shock-absorbing bearing assembly for the pulley of the automobile engine, the surface of the outer ring of the shock-absor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com