Transmission brake based on clutch actuating mechanism

A technology for transmission brakes and actuators, applied in the directions of brake actuators, brake types, axial brakes, etc., can solve the problems of slow response of hydraulic and pneumatic brakes, oil and gas leakage, complex structure, etc., to achieve fast braking response, The effect of stable strength and high control precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

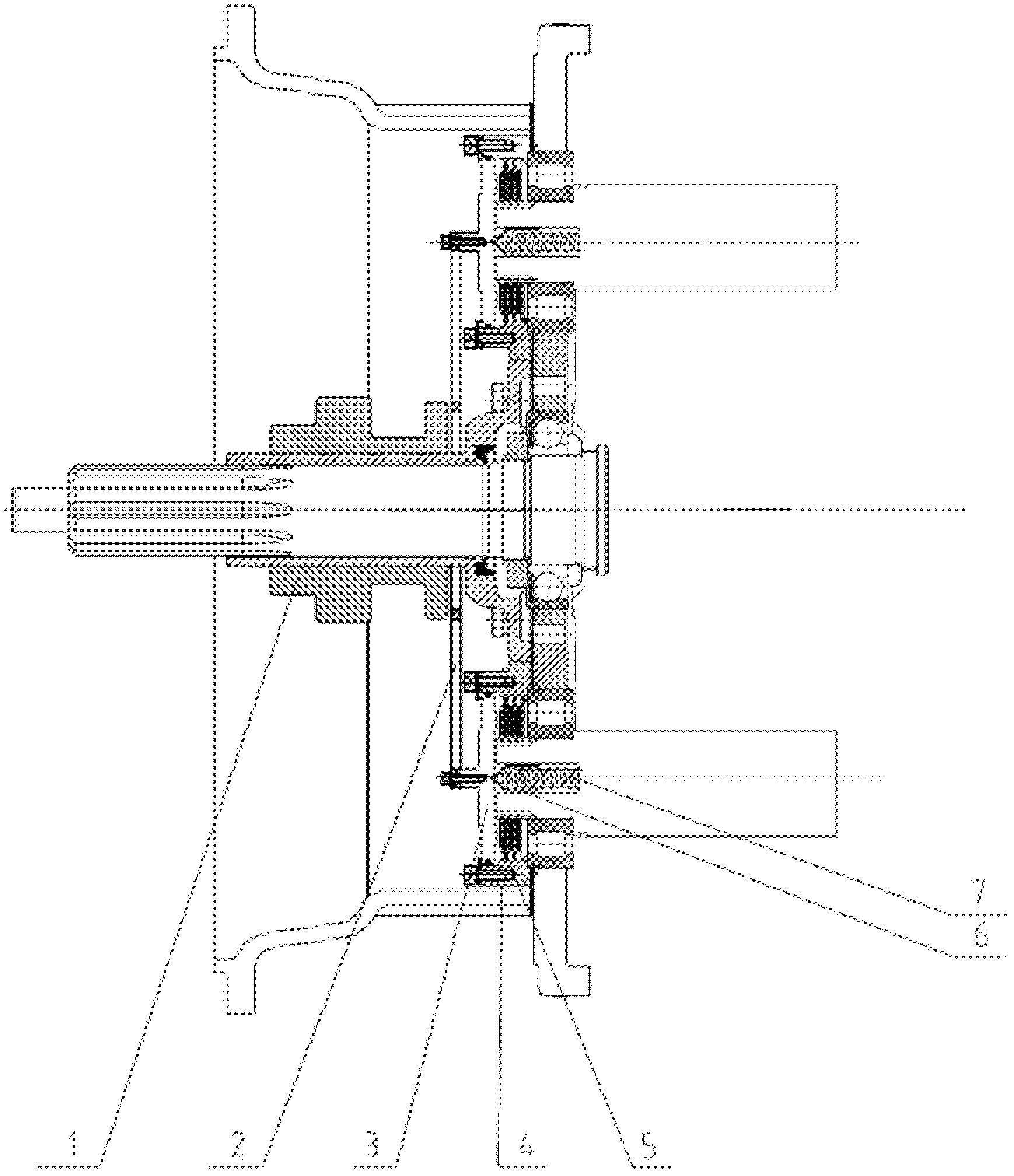

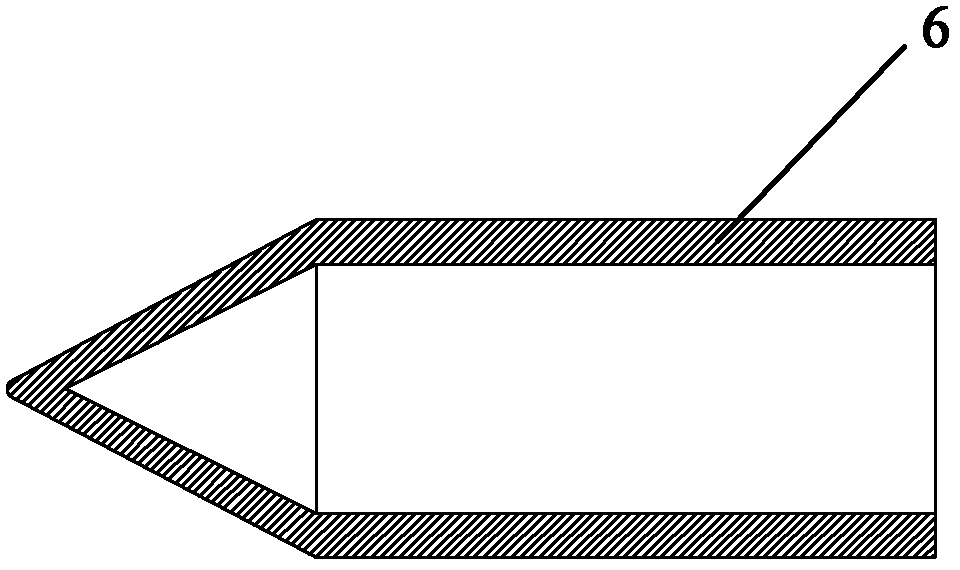

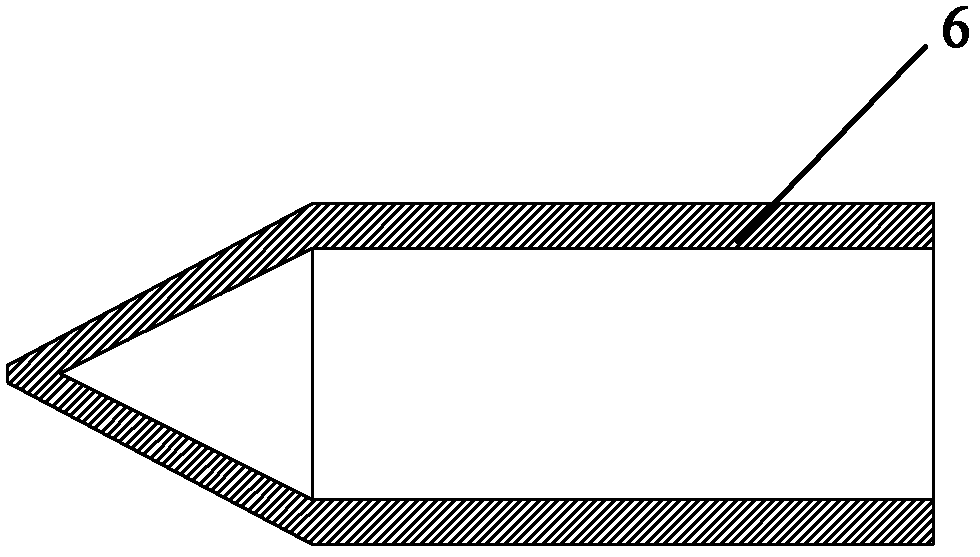

[0017] see figure 1 , the transmission brake based on the clutch actuator of the present invention includes a clutch release bearing 1, a brake bracket 2, a brake piston 3, a brake friction plate 4, a brake steel plate 5, a spring sleeve 6 and a compression spring 7; Piston 3, brake friction plate 4, brake steel plate 5 constitute braking device, and braking device is installed on two intermediate shaft shaft heads. The brake friction plate 4 and the brake steel plate 5 form a friction pair.

[0018] The way of the brake bracket 2 may not be limited to this mechanical structure, and electronic sensing and hydraulic drive or electromagnetic drive may also be used, as long as the drive of the clutch release bearing to the brake piston is realized. The friction pair can also be in the form of a friction cone, that is, the braking is completed through the adaptation of the piston cone to the cone on the intermediate shaft. The brake friction lining 4 is a non-metal material, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com