Transmission mechanism

A technology of transmission mechanism and transmission device, which is applied in the direction of transmission device, mechanical equipment, belt/chain/gear, etc., which can solve the problems of low precision retention, unguaranteed precision, wear and tear of transmission control, etc., and achieve low wear and simple and reliable structure , high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

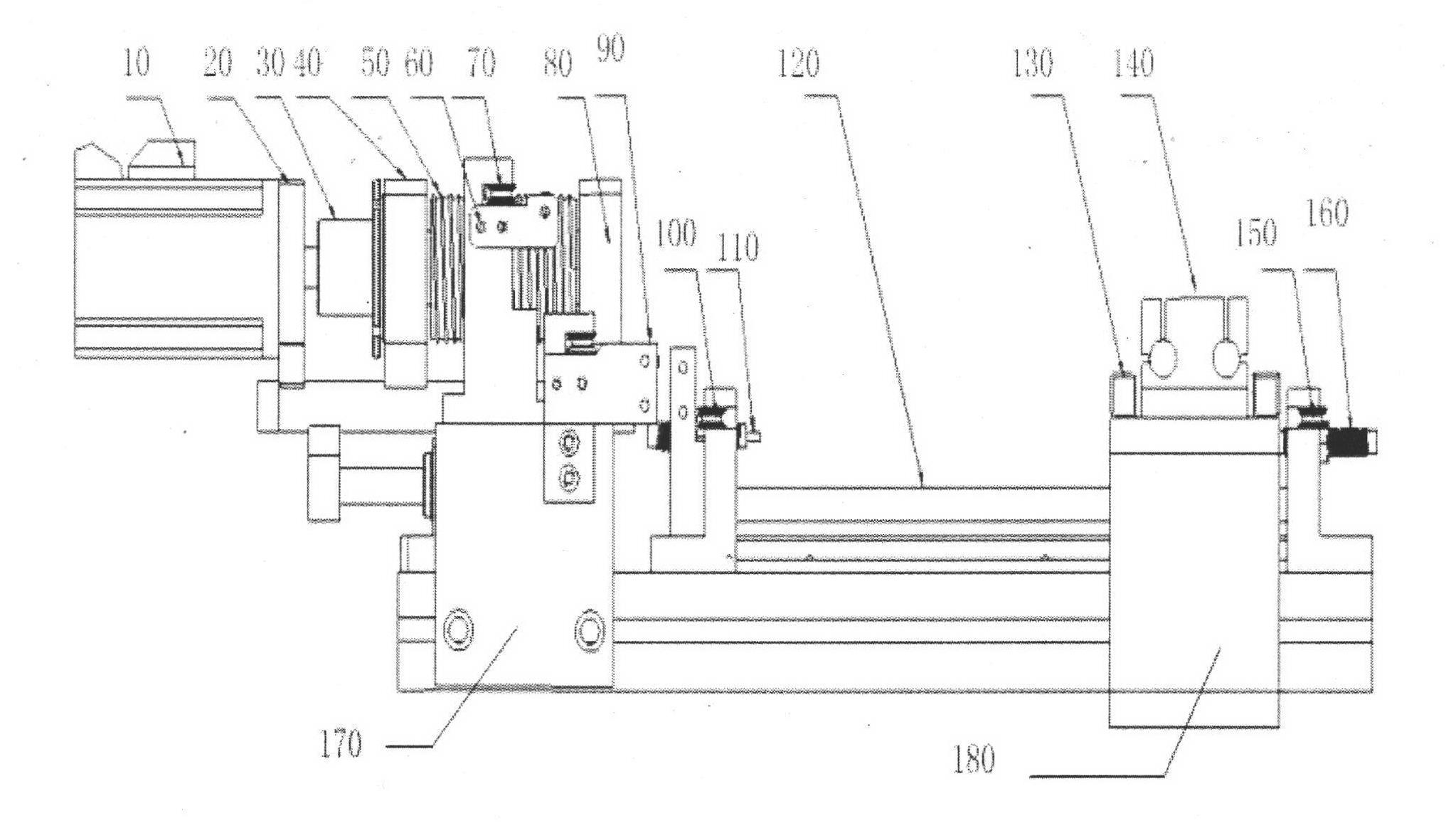

[0024] see figure 1 , a transmission mechanism, comprising: a servo motor 10, a motor plate 20, a coupling 30, a first lead frame 40, a helical roller 50, a second lead frame 60, a first lead wheel 70, a bearing seat 80, a third Lead frame 90, second guide wheel 100, first buffer 110, guide rail 120, crimping frame 130, tension frame 140, third guide wheel 150, second buffer 160, first pedestal 170, second pedestal 180 .

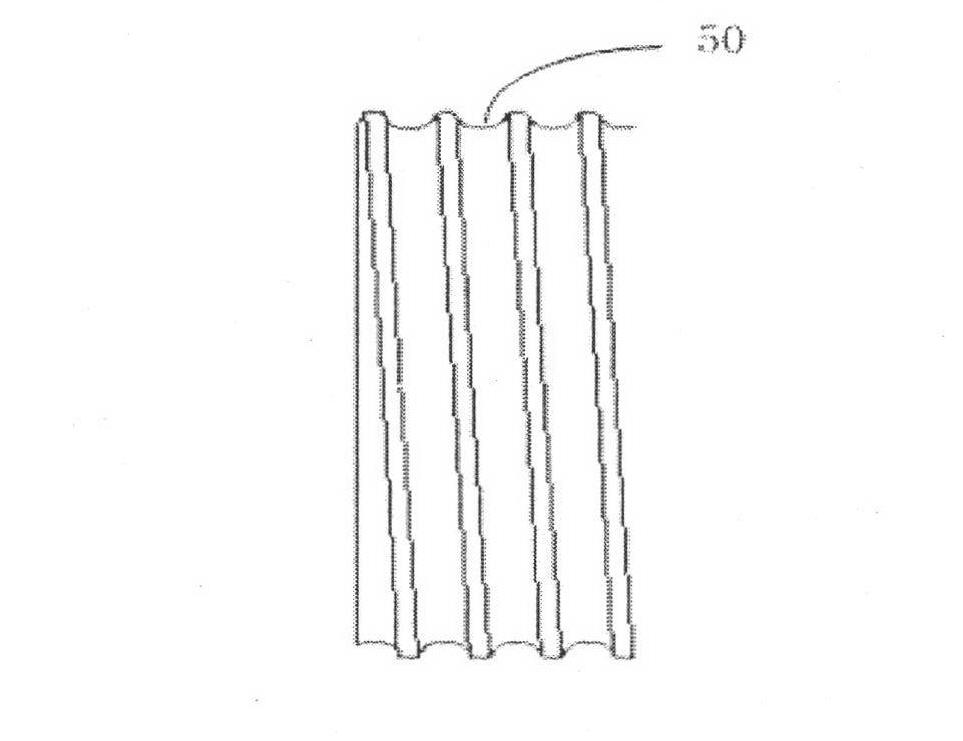

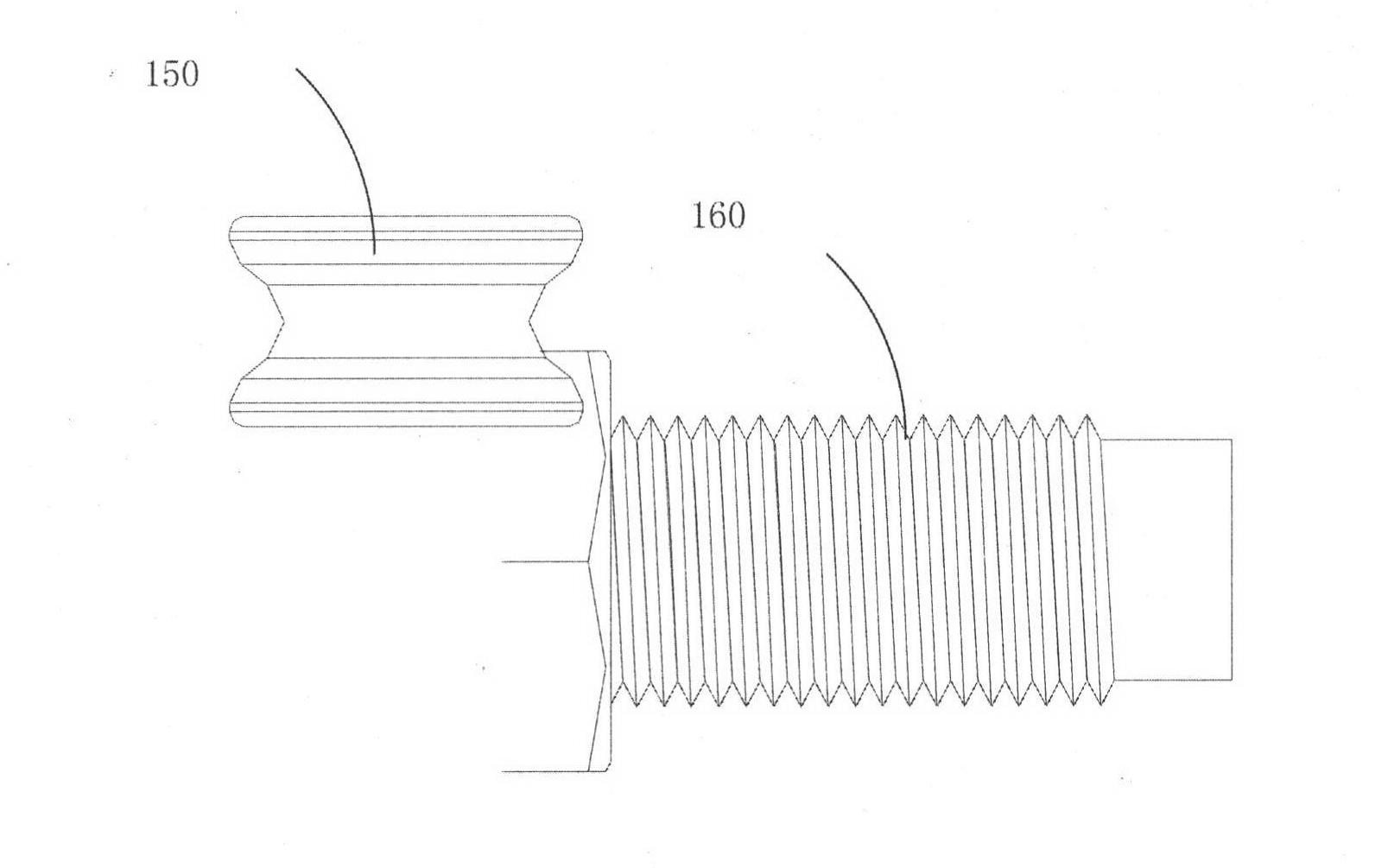

[0025] Servo motor 10, motor plate 20, shaft coupling 30 form driving device; Two guide wheels 100 and the first buffer 110 form a steel wire transmission mechanism; the crimping frame 130, the tension frame 140, the third guide wheel 150, and the second buffer 160 form a steel wire conveying mechanism, wherein the spi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com