Gasket

A sealing ring and sealing lip technology, which is applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve problems such as sealing lip leakage and achieve high robustness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

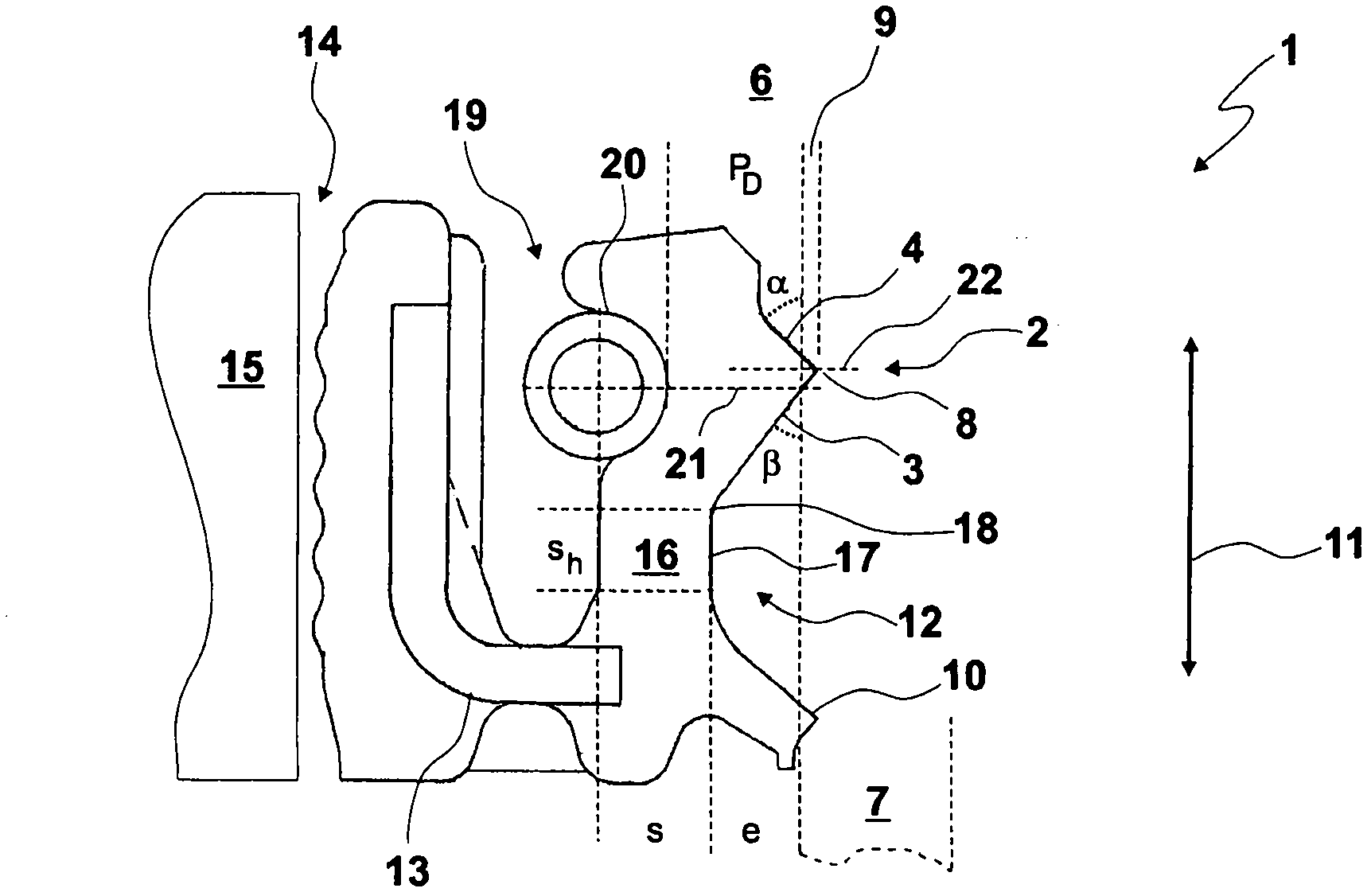

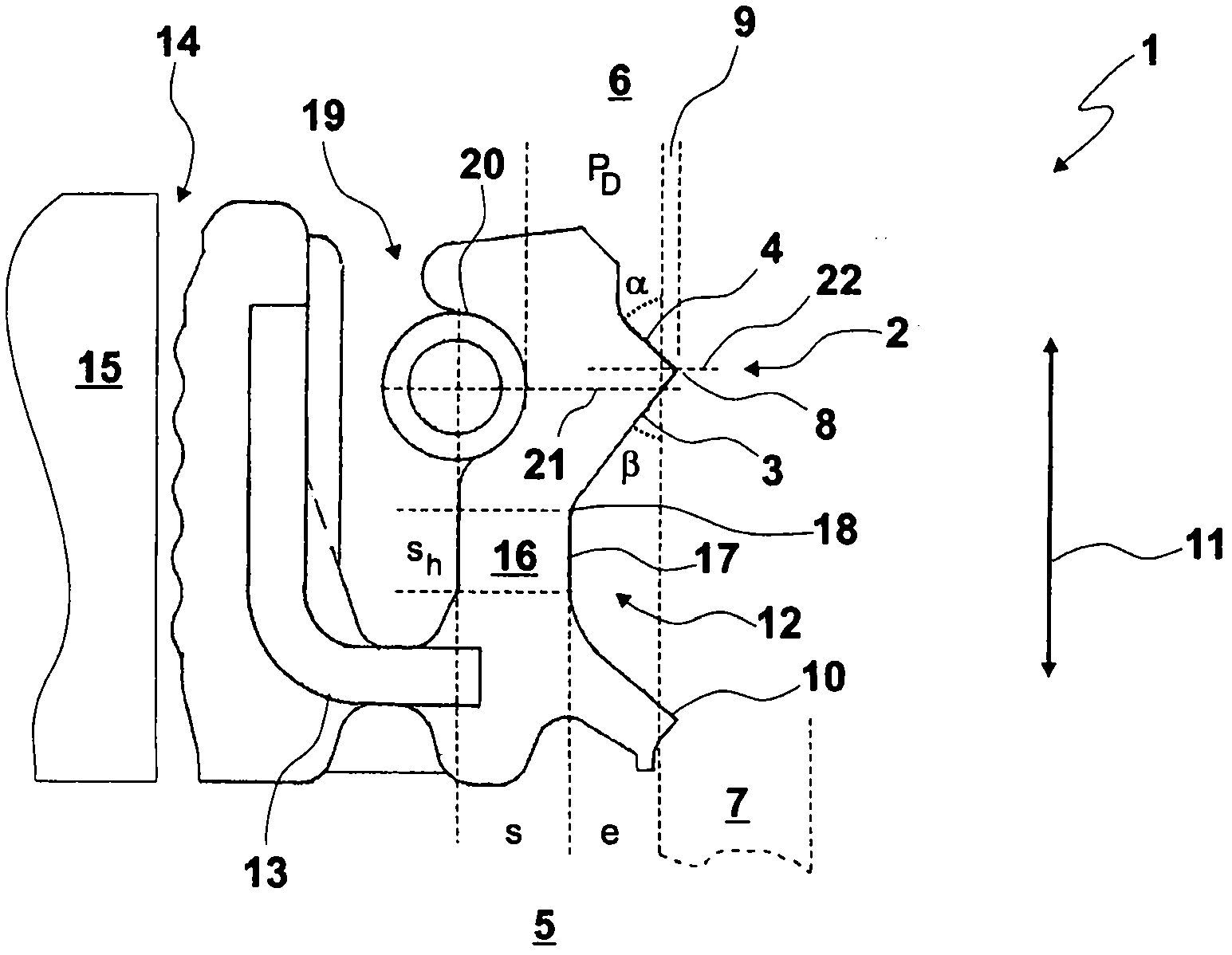

[0040] Such as figure 1 One possible embodiment shown in Dimensional Variations

[0041] parameters

Favorable value range

preferred value range

P D

0.8 to 1.6mm

1.1 to 1.3mm

s

0.6 to 1.2mm

0.8 to 1.0mm

s h

0.4 to 1.1mm

0.6 to 0.9mm

e

0.4 to 1.0mm

0.6 to 0.8mm

α

30 to 45 degrees

35 to 40 degrees

β

37 to 50 degrees

42 to 45 degrees

[0042] exist figure 1 In the embodiment shown, all combinations of the above-mentioned values for the parameters are permissible and applicable.

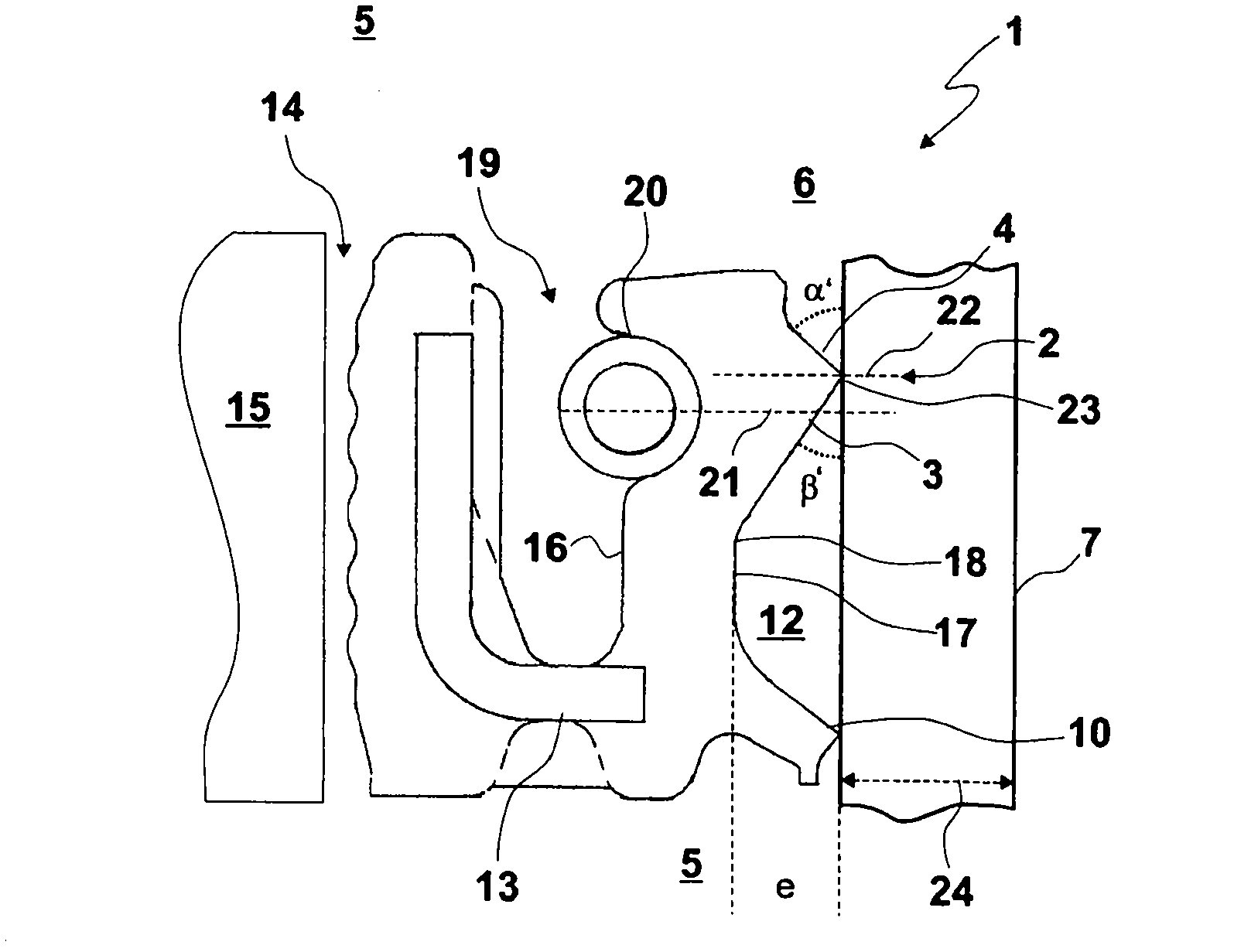

[0043] exist figure 2 is shown in the mounting position with the shaft 7 according to the figure 1 The sealing ring 1. Here, the first angle β' and the second angle α' in the installed position differ from the first angle β' and the second angle α in the unassembled state. Furthermore, a contact surface 23 is formed when the shaft 7 is mounted.

[0044] In the installed po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com