High-temperature and high-pressure bellow compensator

A high-temperature, high-pressure, corrugated pipe technology, which is applied to expansion compensation devices for pipelines, pipe components, pipes/pipe joints/fittings, etc., can solve major accidents, abnormal operation of pipe network systems, and rupture of bellows compensators, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

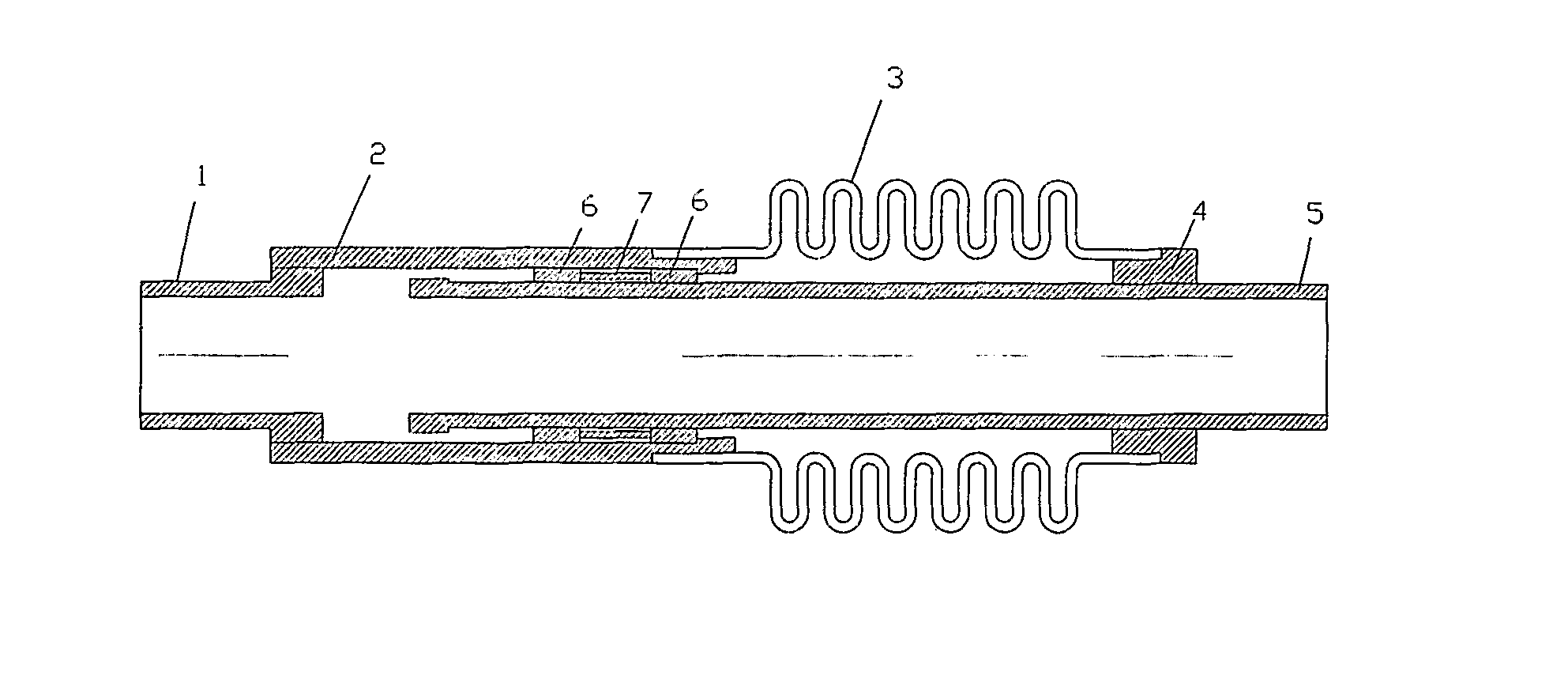

[0015] figure 1 It is a schematic diagram of the overall structure of the high-temperature and high-pressure bellows compensator in the embodiment of the present invention; a bellows compensator, consisting of a left connecting pipe 1, a bellows left connecting pipe 2, a bellows 3, a bellows right connecting pipe 4, an inner sleeve 5, Self-lubricating sliding bearing 6, intermediate ring 7. The bellows left connector 2, the bellows 3, and the bellows right connector 4 are fixedly connected in series in sequence, and all are sleeved on the inner sleeve 5. The left connector 1 is fixedly connected with the left end of the corrugated pipe left connector 2 and the corrugated pipe right connector 4 is fixed set On the inner sleeve 5, the inner sleeve 5, the right bellows connection pipe 4, the bellows 3, the left bellows connection pipe 2 and the left connection pipe 1 are all connected by welding. There is a ring-shaped inner convex ring at the rightmost end of the inner surface of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com