Method for displacing impurities at bottom of water sealed tank of gas holder without shutdown as well as gas holder

A technology of water-sealed tanks and gas cabinets, which is applied to adjustable-capacity gas storage tanks, gas/liquid distribution and storage, and mechanical equipment, and can solve problems such as time-consuming replacement work, half-water gas leakage, and danger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

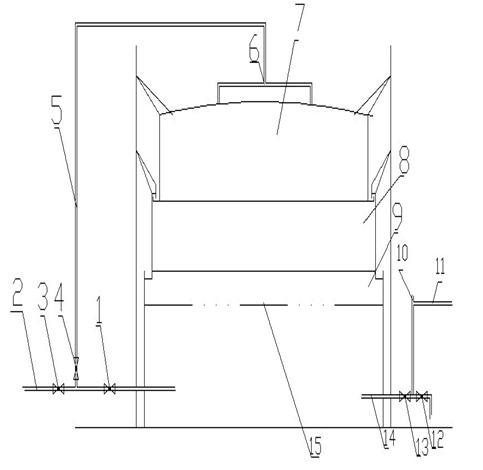

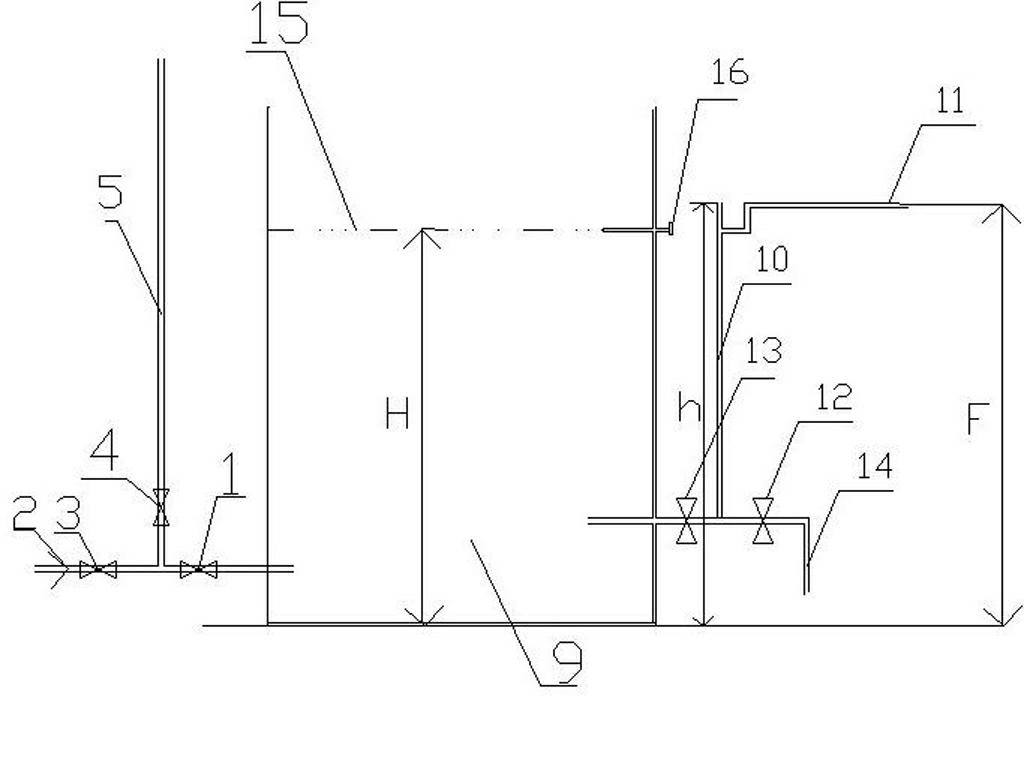

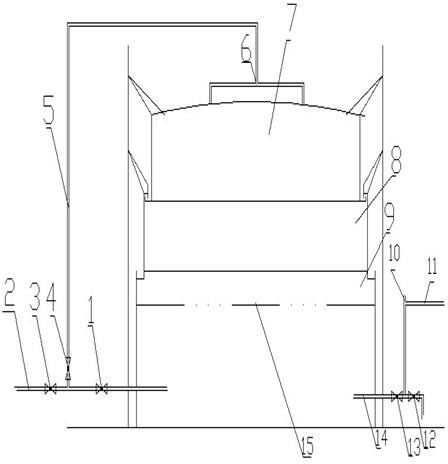

[0016] Transform the existing gas cabinet into a gas cabinet that can replace impurities at the bottom of the gas cabinet without stopping the vehicle, seal the original overflow port with a blind plate (16), and set a Sewage pipe (14), a root valve (13) and a secondary valve (12) are provided on the sewage pipe, and a vertical overflow pipe (10) is provided on the pipeline between the root valve and the secondary valve. The top of the flow pipe is open, the upper part of the vertical overflow pipe is provided with a horizontal overflow pipe (11) which is horizontally arranged and communicated with the vertical overflow pipe (10), and a replenishment pipe ( 2), the water supply pipe is provided with a main water supply valve (3) and a lower water supply valve (1). The height h from the top of the vertical overflow pipe (10) to the ground is greater than or equal to the height H of the liquid surface, which is 0-18 cm, preferably 13-16 cm, and the height F of the horizontal ove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com