Circulating fluidized bed boiler technology for pure-burning low heating value coal gangue

A technology of circulating fluidized bed and coal gangue, which is applied in the direction of fluidized bed combustion equipment, fuel for combustion in a molten state, and combustion methods, etc., and can solve problems such as wear of the heating surface, low volatile content of gangue, and inability to ensure that gangue is burned out. , to achieve the effect of promoting environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

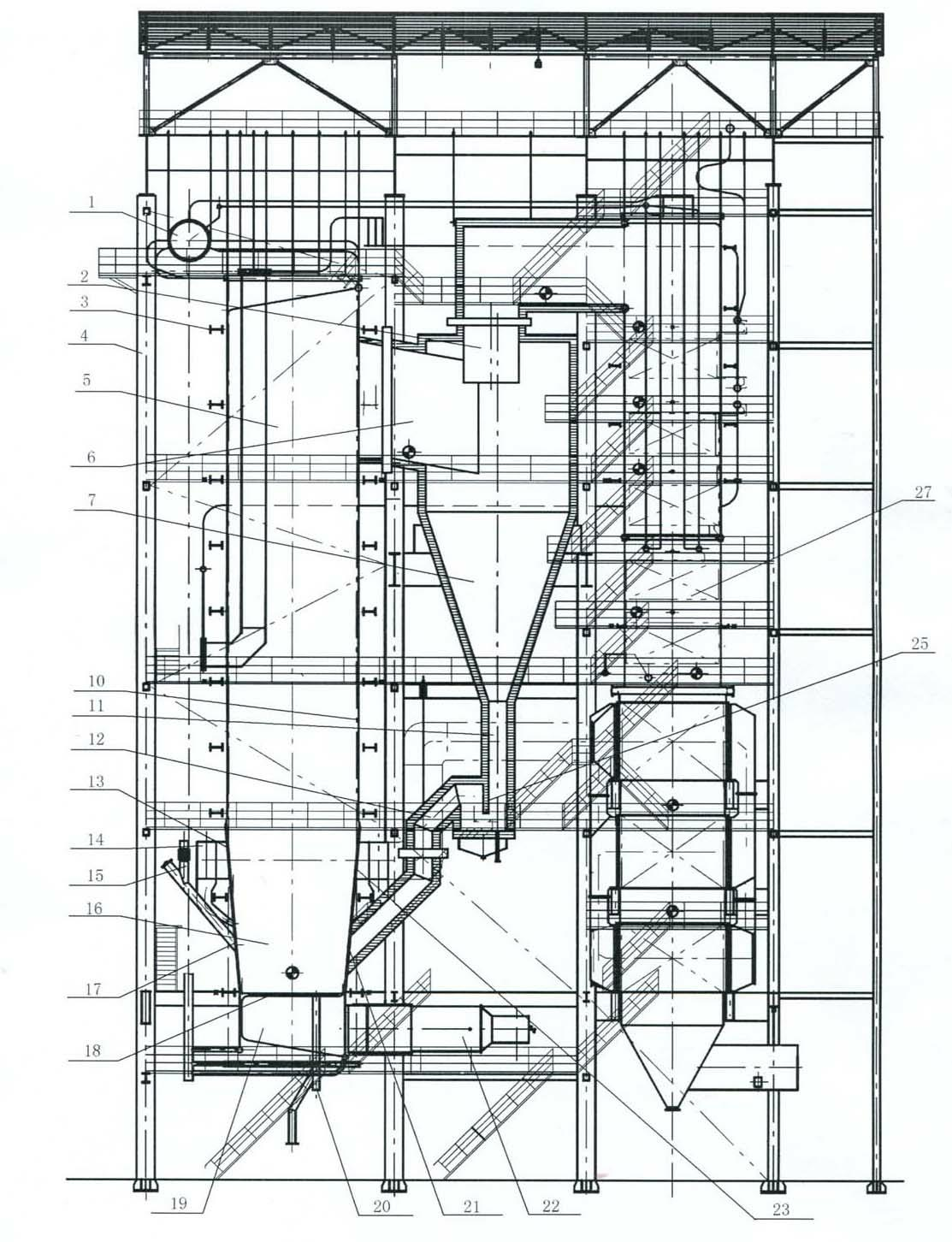

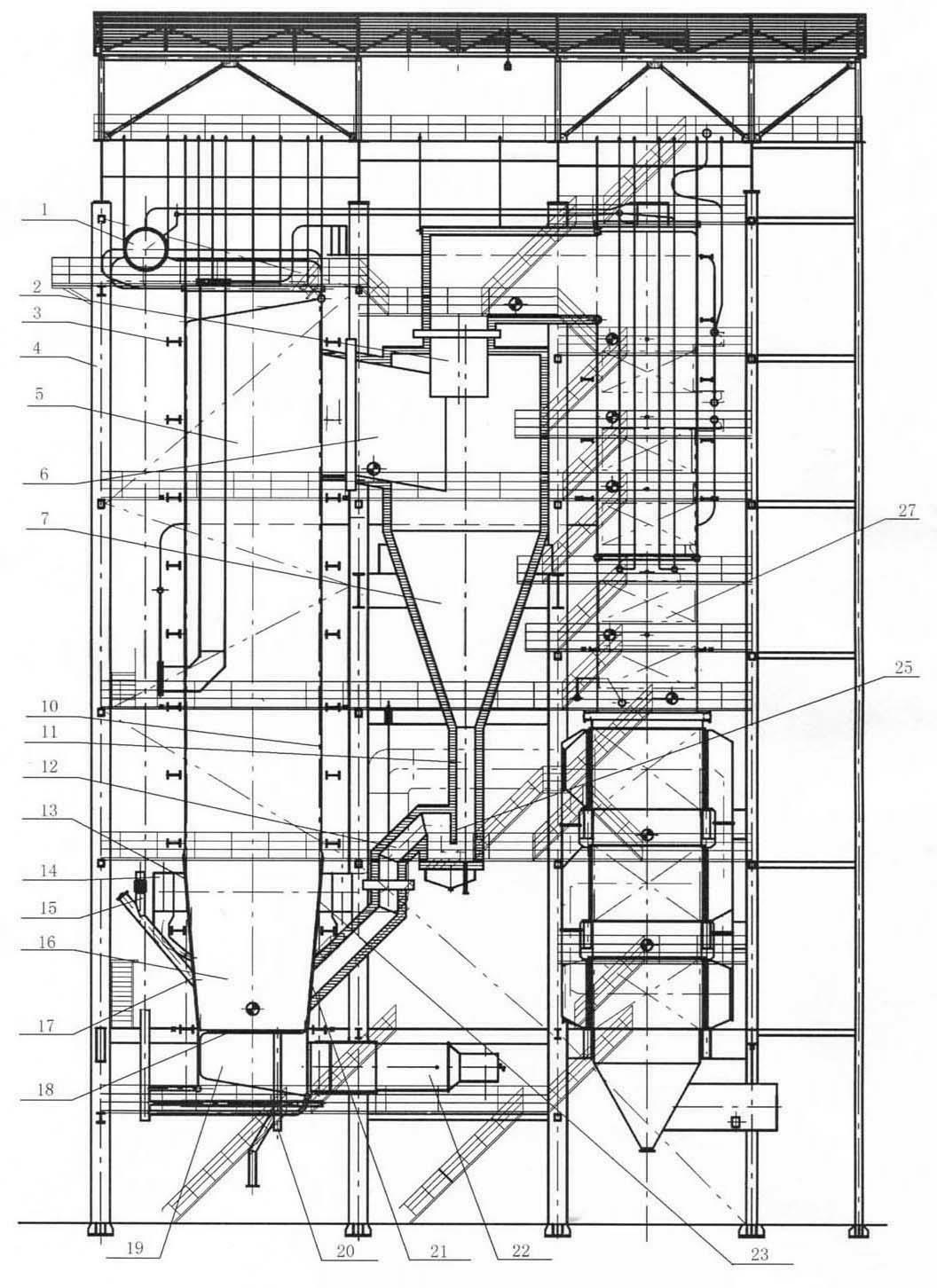

[0040] A circulating fluidized bed boiler technology for pure burning of low calorific value coal gangue mainly adopts a circulating fluidized bed boiler with low wind speed, high bed temperature, large bed surface, thick material layer, and remote slag discharge; the technology consists of circulating fluidized bed boiler The structure improvement and the process parameters of pure burning low calorific value coal gangue circulating fluidized bed boiler combustion and structural design are composed of two parts:

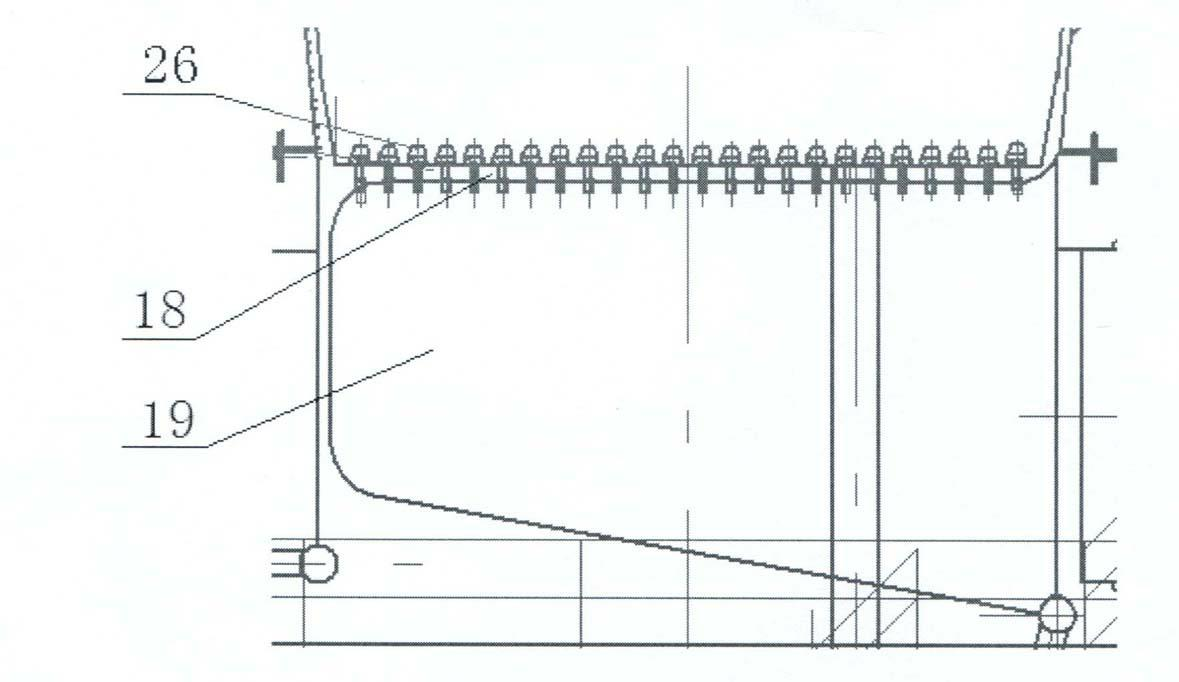

[0041] like figure 1 and figure 2 As shown, the circulating fluidized bed boiler mainly includes a drum 1, a membrane-type water-cooled fireplace chamber 5, an adiabatic cyclone separator 7, a material return system 12 and a vertical shaft flue 27; the membrane-type water-cooled fireplace chamber 5 is fixed on a rigid beam 3 The upper part is connected to the boiler frame 4; the upper outlet 6 of the membrane type water-cooled fireplace chamber 5 is connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com