Totally closed oil bath type reciprocating motion supporting device for cement clinker grate cooler

A technology of cement clinker and reciprocating motion, which is applied in clinker production, cement production, and treatment of discharged materials. It can solve problems such as high cost, many system failures, and increased energy consumption, so as to reduce energy consumption and extend maintenance cycles. , the effect of reducing failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

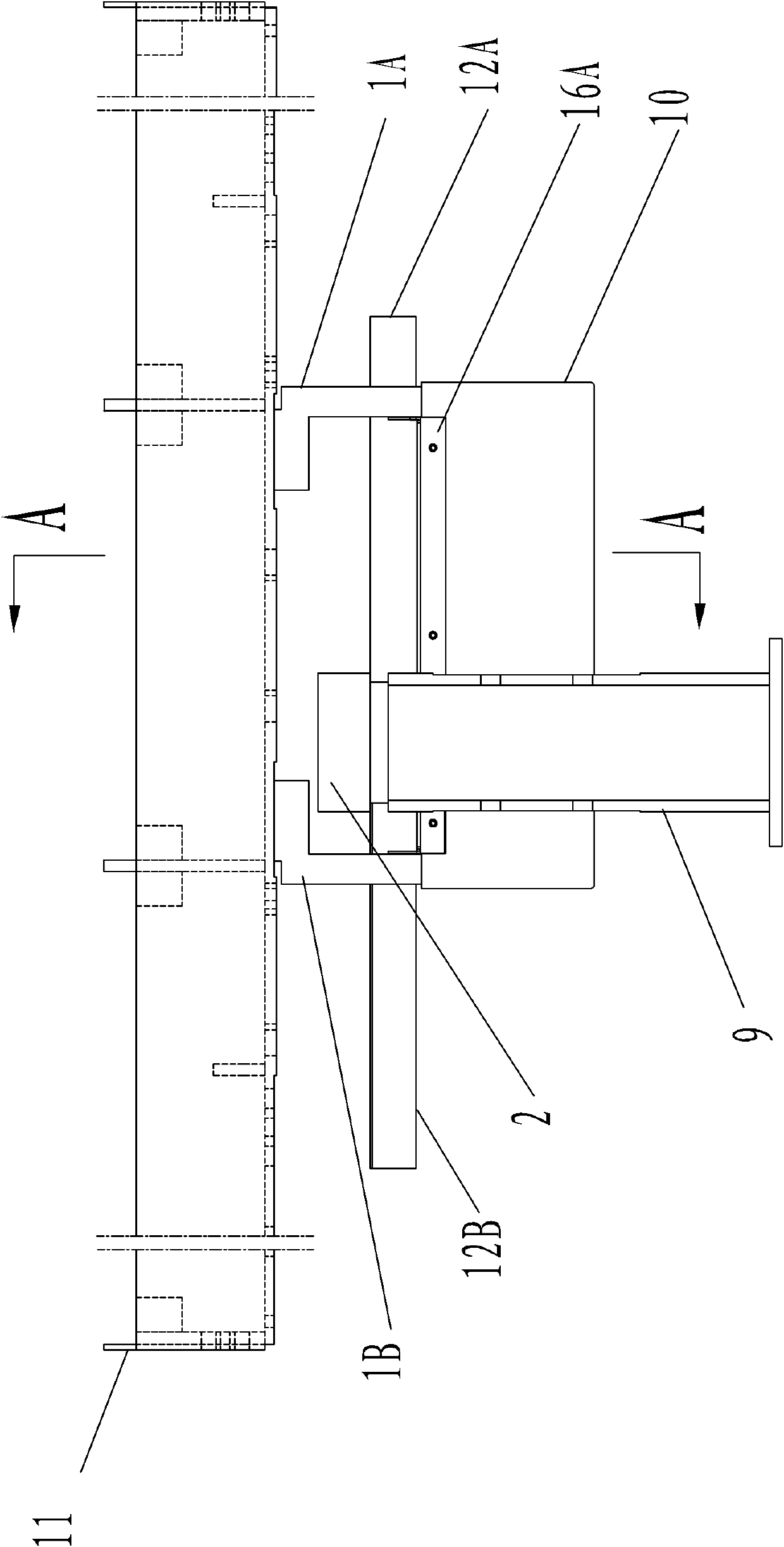

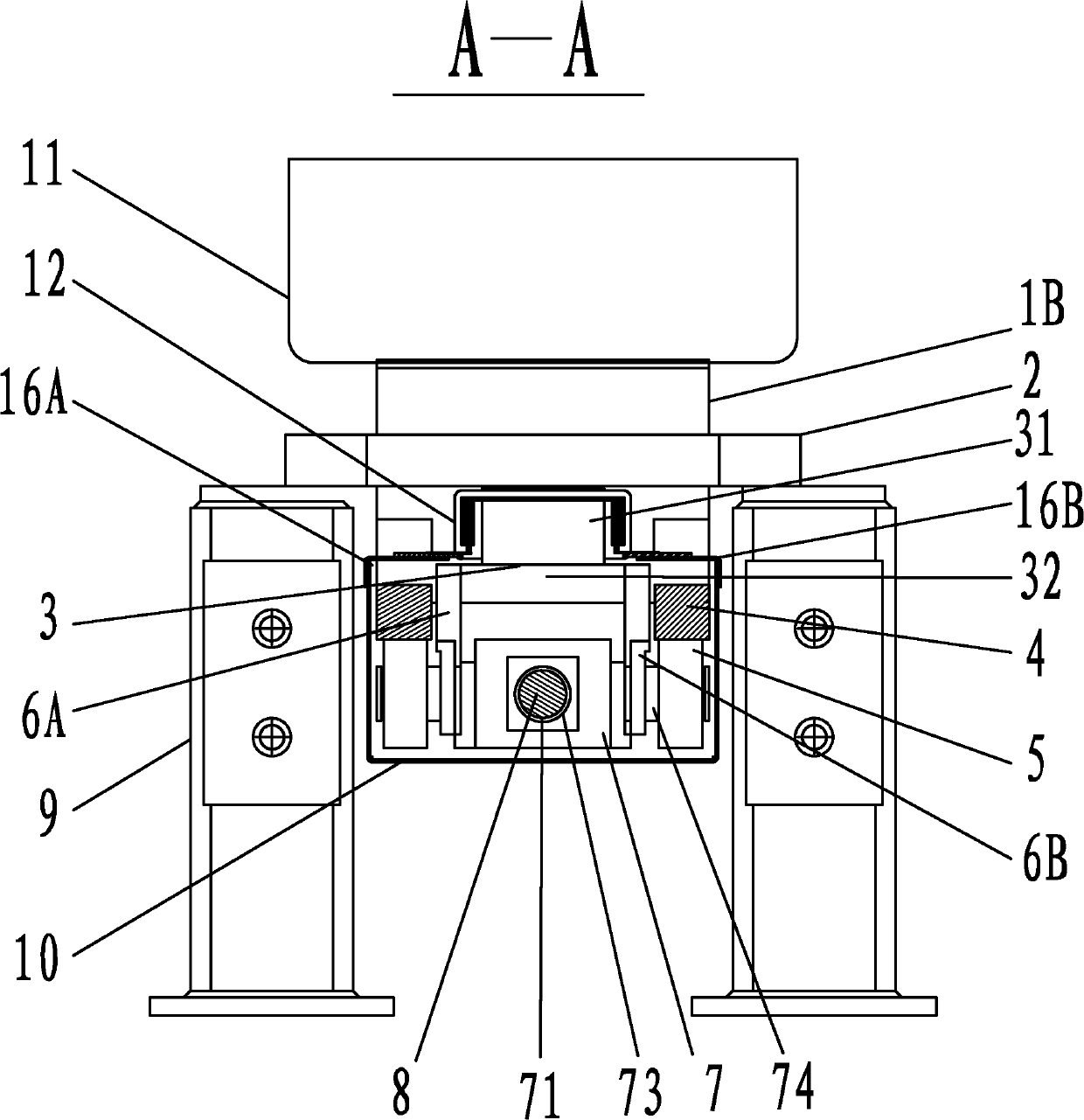

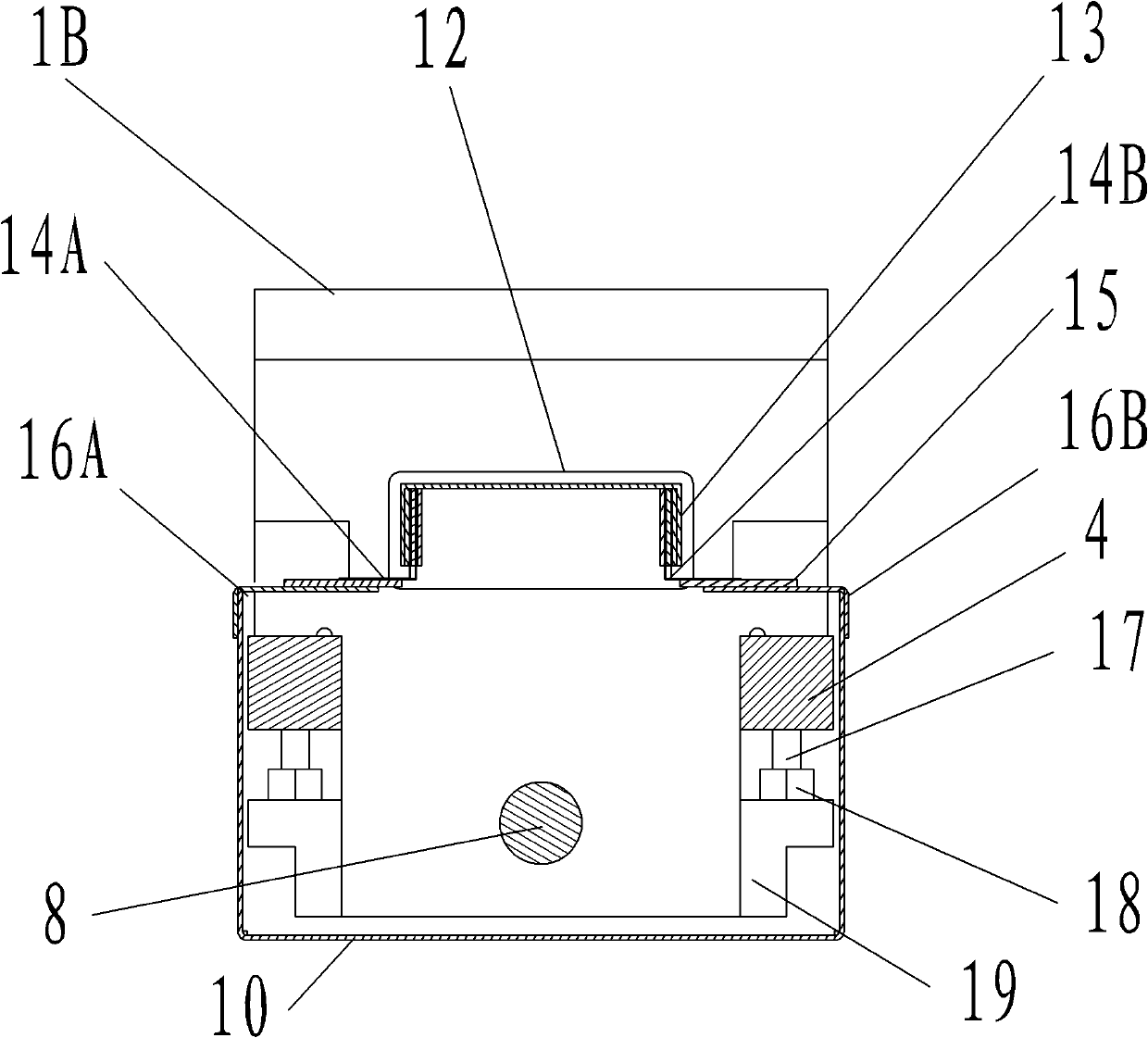

[0018] Figure 1 to Figure 6 A fully enclosed oil bath type reciprocating support device for a cement clinker grate cooler is shown, which is characterized in that it includes two right-angle support bending plates 1A and 1B, a main hanging beam 2, a connecting block 3, a bearing guide beam 4, a guide Block 7, guide shaft 8, shaft sleeve 73, bearing 5, lubricating oil box 10 and sealing cover 12, two right-angle supporting bent plates 1A, 1B are relatively fixed on the shuttle-type grate plate unit along the longitudinal direction of the bar-shaped shuttle-type grate plate unit 11 At the bottom, between the two right-angle supporting bent plates 1A and 1B, the main hanging beam 2 is set across the middle, and the two ends of the main hanging beam 2 are fixedly connected with the support columns 9 arranged on the lateral sides of the shuttle-type grate plate unit 11; The center of the bottom of the beam is connected to the guide block 7 through the connecting block 3. The cente...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com