Displacement detection system with twist error correcting function

A technology of displacement detection and function, which is applied in the field of displacement detection system with the function of correcting torsion error, can solve the problem that the measurement accuracy of the measuring instrument cannot be fully utilized, so as to improve the reading stability and self-test ability, and reduce the torsion effect of error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

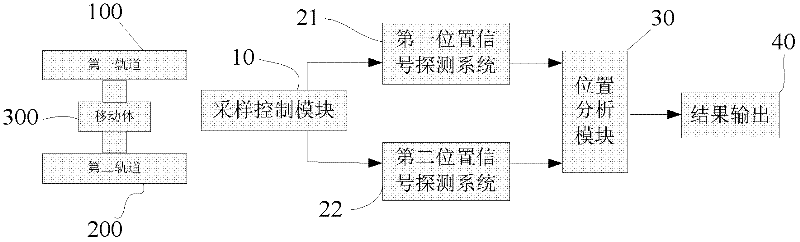

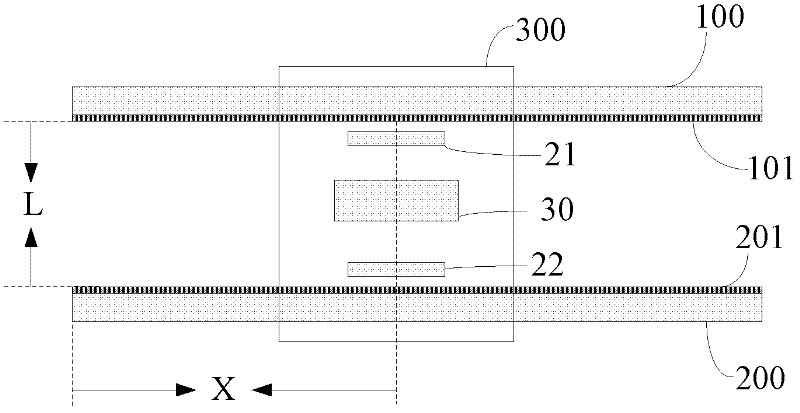

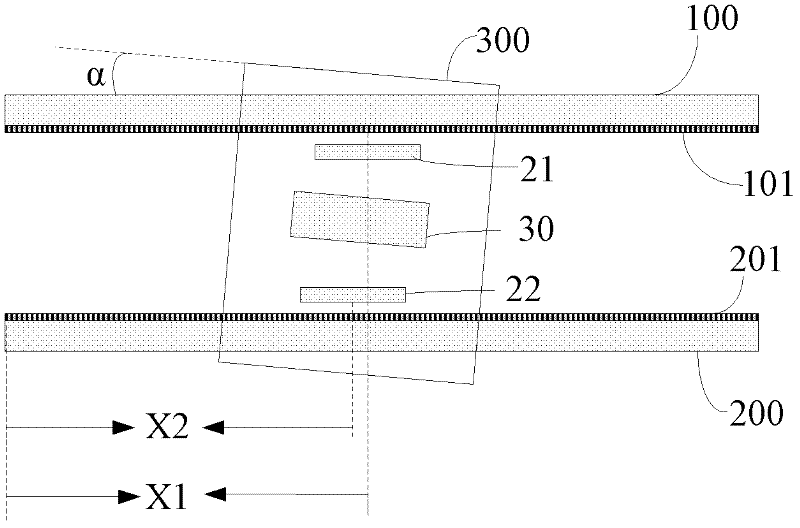

[0010] combine Figure 1 to Figure 3 Describe this embodiment, a displacement detection system with the function of correcting torsion errors, the system includes a first standard grating 101, a second standard grating 201, a sampling control module 10, a first position signal detection system 21, and a second position signal detection system 22 and a location analysis module 30;

[0011] The position analysis module 30 receives position signals from the first position signal detection system 21 and the second position signal detection system 22, and the first position signal detection system 21 and the second position signal detection system 22 are unified by the sampling control module 10 The acquisition signal is sent out, and the position analysis module 30 analyzes and compares the displacement signals of the moving body 300 obtained from the first position signal detection system 21 and the second position signal detection system 22 relative to the first standard grating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com