Selective laser sintering indirect manufacturing method of individuation tongue side orthodontic bracket

A technology of selective laser sintering and orthodontic brackets, which is applied in the direction of manufacturing tools, brackets, program control, etc., can solve the problems of increasing the burden on patients, affecting the treatment effect, and failing to meet the individual needs of patients, so as to save procedures and apply Wide range, well-coordinated effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

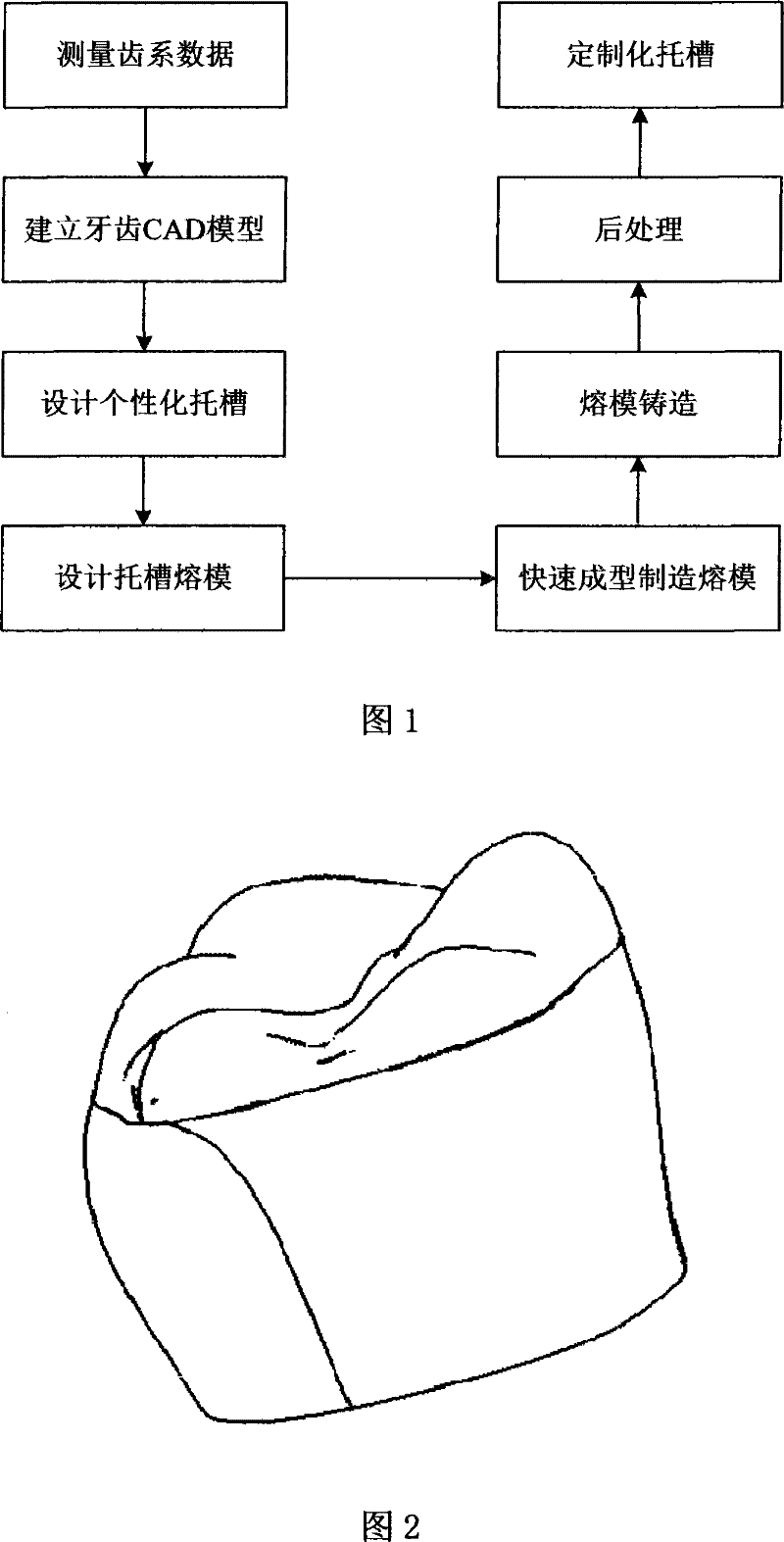

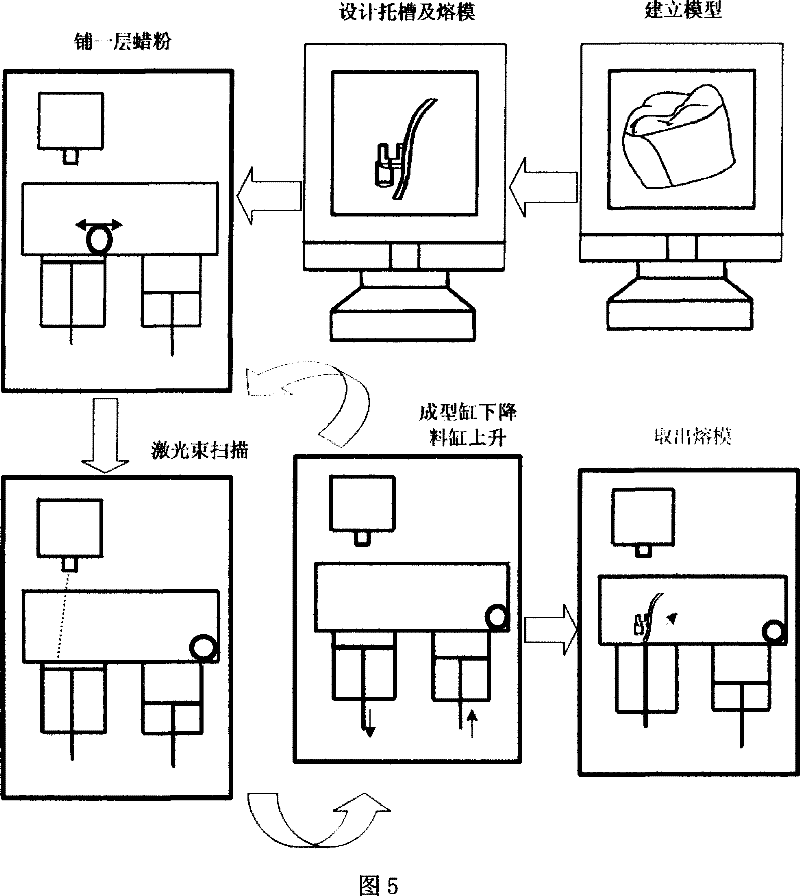

[0032] As shown in Figure 1, the technological process of the indirect manufacturing method of selective laser sintering of individualized lingual orthodontic brackets of the present invention is:

[0033] (1) Measure the dentition data to obtain the shape and structure parameters of the teeth; the measurement of the dentition data adopts CT tomography or a non-contact three-dimensional scanner to directly scan the teeth, or firstly make a model of the teeth and then perform three-dimensional scanning measurement, the said The scanning accuracy is better than 0.02mm;

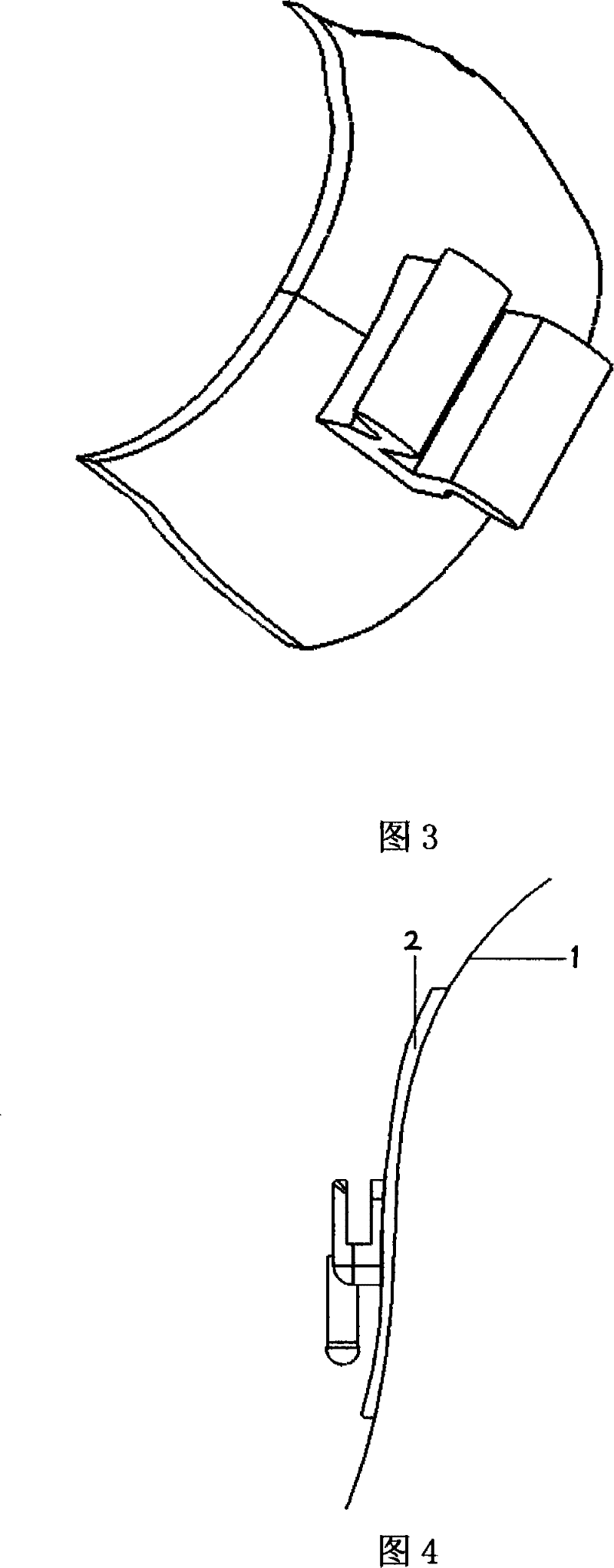

[0034] (2) According to the dentition data, the three-dimensional CAD model of the tooth as shown in Figure 2 is established by reverse engineering method, and stored in the computer in STL format; the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com