Spherical all-dimensional loading device used for building structural node test

A loading device, an all-round technology, applied in the testing, measuring devices, instruments, etc. of machine/structural components, which can solve the problems of poor generality of auxiliary components, backward synchronous automatic loading and data acquisition technology of loading system, and inability to reuse.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

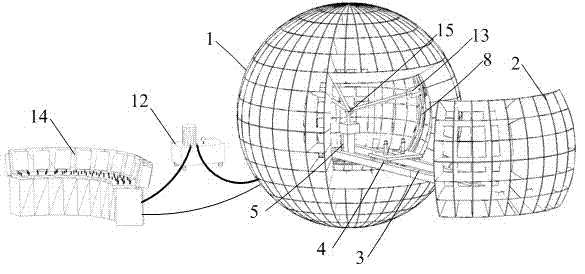

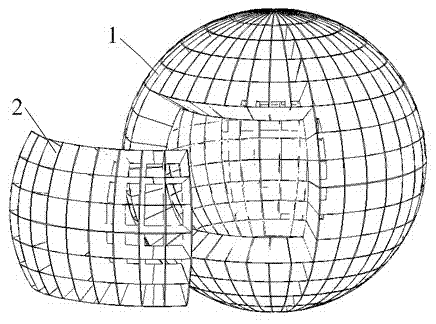

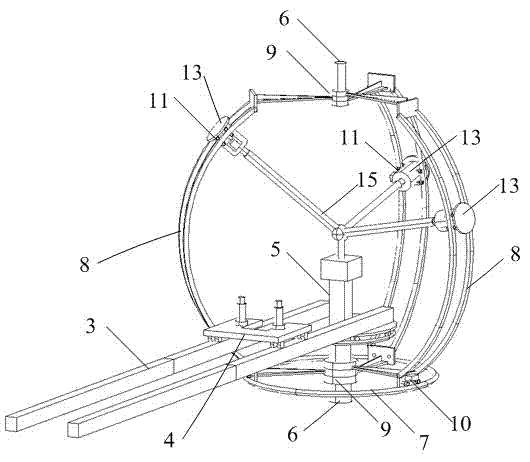

[0022] As shown in the figure, the spherical omnidirectional loading device of the present invention includes a spherical steel reaction force frame, a loading positioning adjustment wheel-rail system, a jack hydraulic servo loading system and a main console. The loading positioning adjustment wheel-rail system is installed inside the spherical steel reaction frame, the jack hydraulic servo loading system is installed on the loading positioning adjustment wheel-rail system, and the main console is respectively connected with the loading positioning adjustment wheel-rail system and the jack hydraulic servo loading system.

[0023] Among them, the steel reaction frame includes the main structure of the reaction frame 1, the door opening of the reaction frame 2, the transport wheel rail 3, the transport trolley 4, and the test piece pedestal 5; the transport wheel rail 3 and the test piece pedestal 5 are all installed on the reaction force frame On the main structure 1, the transp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com