Method for preparing hydrogel wound dressing through low-temperature biological 3D printing technology

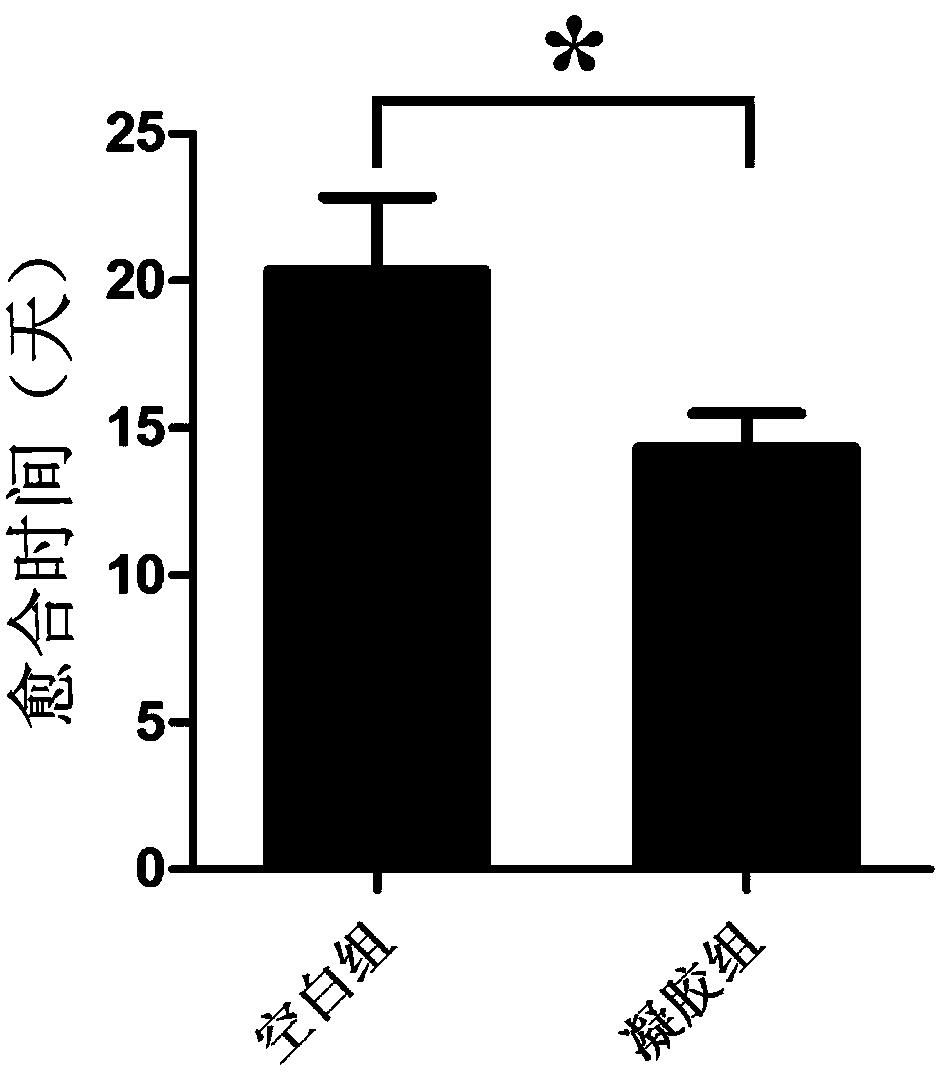

A 3D printing and hydrogel technology, applied in the field of medical products, can solve the problems of poor regeneration of granulation tissue on exposed wounds, rapid loss of active ingredients, and aggravated nursing tasks, so as to facilitate long-term storage and transportation, and accelerate wound regeneration and repair Speed, the effect of promoting the regeneration of granulation tissue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

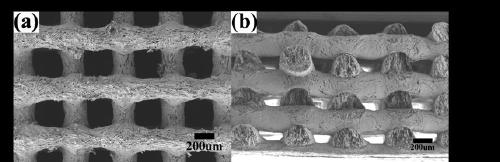

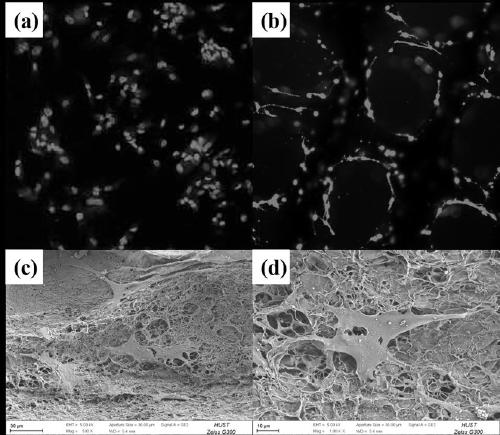

[0031] A method for preparing a low-temperature bio-3D printed hydrogel wound dressing: including (1) dissolving 8% sodium alginate (SA) in deionized water, absorbing water to swell for 6 hours at room temperature, and then fully mechanically stirring for 30 minutes; Dissolve gelatin (GA) with a mass fraction of 8% in deionized water, and stir electromagnetically at 40°C for 30 minutes; finally, blend the sodium alginate solution and gelatin solution at a mass ratio of 1:1, and stir thoroughly at 40°C until a uniform A blend solution containing 4% SA and 4% GA.

[0032] (2) Combination of biological factors and hydrogel matrix materials: Add 1ml of 20μg / ml VEGF solution into 9ml of 4%SA / 4%GA blend solution, stir at 37 degrees Celsius for 5 minutes, and finally get 2μg / ml VEGF loaded Hydrogel matrix material; add 1ml 2mg / ml LL-37 solution to 9ml 4%SA / 4%GA blend solution, stir at 37°C for 5 minutes, and finally get a hydrogel matrix loaded with 200μg / ml LL-37 Material.

[0033...

Embodiment 2

[0036] A method for preparing a low-temperature bio-3D printed hydrogel wound dressing, comprising: (1) dissolving 2% sodium alginate (SA) in deionized water, absorbing water and swelling for 6 hours at room temperature, and then fully mechanically stirring for 30 minutes ; Dissolve gelatin (GA) with a mass fraction of 15% in deionized water, and stir electromagnetically at 40 degrees Celsius for 30 minutes; finally, blend the sodium alginate solution and gelatin solution at a mass ratio of 5:1, and stir thoroughly at 40 degrees Celsius until A uniform blend solution containing 4% SA and 4% GA.

[0037] (2) Combination of biological factors and hydrogel matrix materials: Add 1ml of 20μg / ml VEGF solution into 9ml of 4%SA / 4%GA blend solution, stir at 37 degrees Celsius for 5 minutes, and finally get 2μg / ml VEGF loaded Hydrogel matrix material; add 1ml 2mg / ml LL-37 solution to 9ml 4%SA / 4%GA blend solution, stir at 37°C for 5 minutes, and finally get a hydrogel matrix loaded with ...

Embodiment 3

[0041] A method for preparing a low-temperature bio-3D printed hydrogel wound dressing, comprising: (1) dissolving 2% sodium alginate (SA) in deionized water, absorbing water and swelling for 6 hours at room temperature, and then fully mechanically stirring for 30 minutes ; Dissolve gelatin (GA) with a mass fraction of 15% in deionized water, and stir electromagnetically at 40 degrees Celsius for 30 minutes; finally, blend the sodium alginate solution and gelatin solution at a mass ratio of 5:1, and stir thoroughly at 40 degrees Celsius until A uniform blend solution containing 4% SA and 4% GA.

[0042] (2) Combination of biological factors and hydrogel matrix materials: Add 1ml of 20μg / ml VEGF solution into 9ml of 4%SA / 4%GA blend solution, stir at 37 degrees Celsius for 5 minutes, and finally get 2μg / ml VEGF loaded Hydrogel matrix material; add 1ml 2mg / ml LL-37 solution to 9ml 4%SA / 4%GA blend solution, stir at 37°C for 5 minutes, and finally get a hydrogel matrix loaded with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com