Air-cooling cold (hot) water unit experiment device with surface-cooling coil pipe regulation function

A hot water unit and test device technology, applied in the direction of measuring devices, machine/structural component testing, instruments, etc., can solve problems such as poor energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

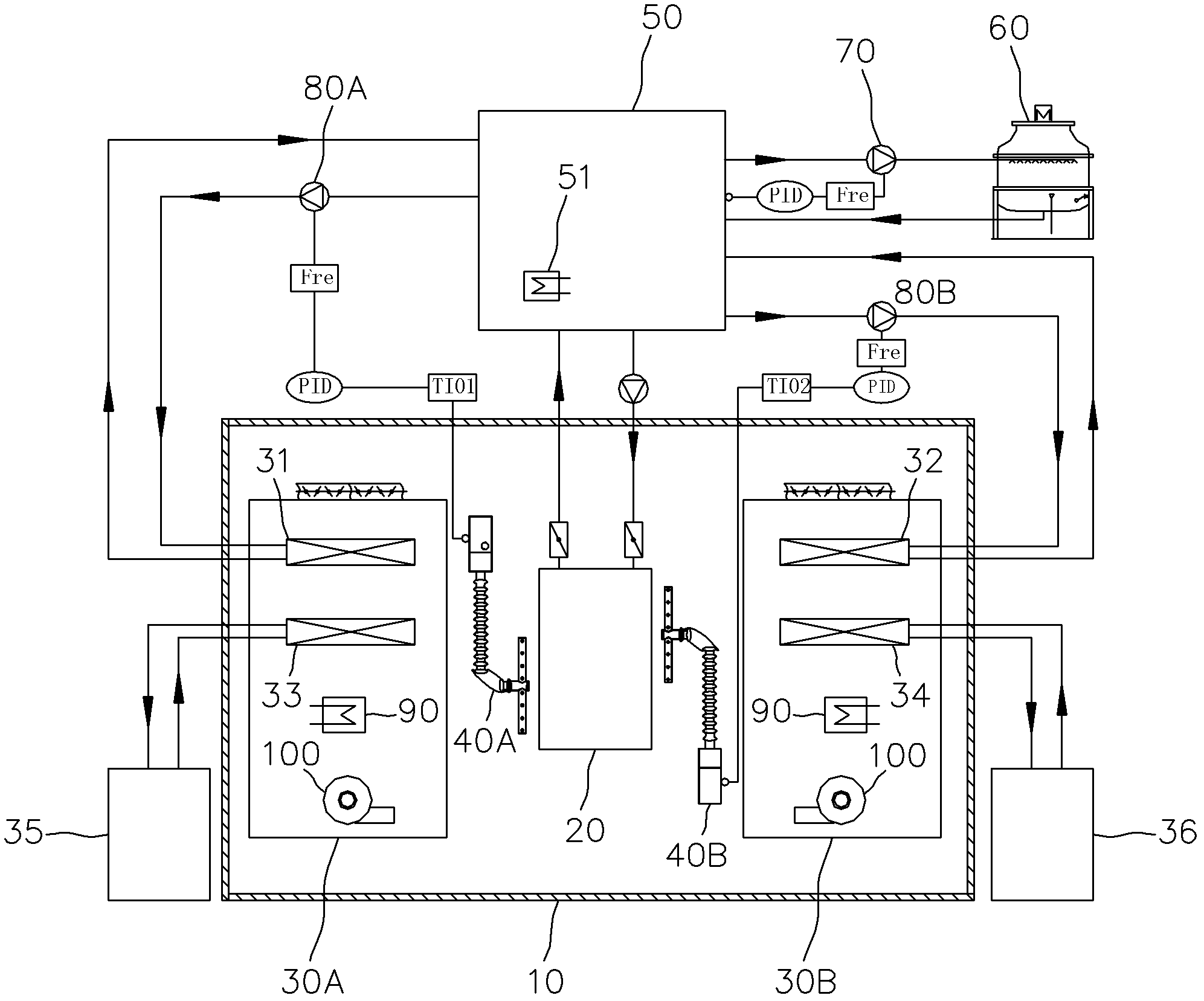

[0030] Such as figure 1 As shown, an air-cooled chiller and hot water unit test device with a surface cooling coil adjustment function includes a closed test room 10, and a test machine 20 is arranged in the test room 10, and the two sides of the test machine 20 are respectively A first air handling unit 30A and a second air handling unit 30B are provided, and the tested machine 20 communicates with a constant temperature water tank 50 arranged outside the test room 10 through pipes, and both sides of the tested machine 20 are provided with Condenser, and the return air of both sides of the condenser is respectively provided with a first air temperature sampler 40A and a second air temperature sampler 40B; said first air handling unit 30A is provided with a first surface cooling coil 31, The second air handling unit 30B is provided with a second surface cooling coil 32, and the first surface cooling coil 31 and the second surface cooling coil 32 are respectively connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com