Sample observation surface flattening device for microscope and sample flattening method

A sample observation and microscope technology, which is applied in microscopes, optics, instruments, etc., can solve the problems of difficult sample observation surfaces and the influence of sample observation effects, so as to avoid unclear mirror images of microscope observation, reduce the difficulty of preparation, and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below through specific embodiments in conjunction with the drawings. The following examples only further illustrate the present invention, and should not be construed as limiting the present invention.

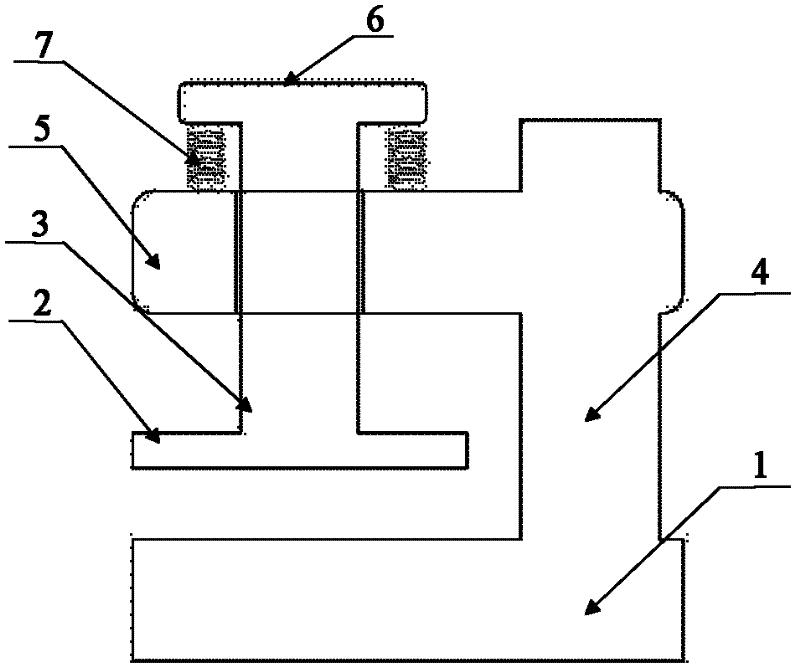

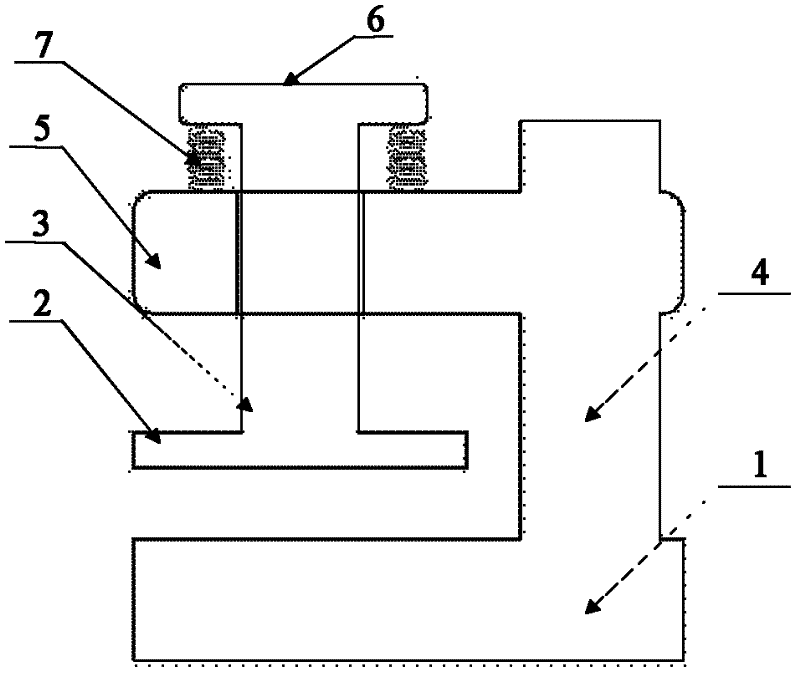

[0025] The microscope sample observation surface flattening device of the present invention, such as figure 1 As shown, it includes a seat body, a pressure plate 2 and a spring 7; wherein the seat body includes a base 1 and a support rod 4, the support rod 4 has a rod arm 5, which extends horizontally from the support rod 4, is parallel to the base 1, and Located directly above the base 1; the pressing plate 2 has a pressing rod 3 extending from its upper surface, and the extending end of the pressing rod 3 has a handle 6. The lever arm 5 has an opening through which the pressing rod 3 is movably linked with the lever arm 5 so that the pressing plate 2 can move linearly in the vertical direction of the upper surface of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com