Suspension end insulation structure with transformer coil inserted with shielding wire

A technology of transformer coils and shielded wires, which is applied in the direction of transformer/inductor coil/winding/connection, preventing/reducing unnecessary electric/magnetic influence, etc., and can solve the problems of difficult guarantee of reliability, waste of raw materials, increase in transformer volume, etc. problems, to achieve the effect of increasing the partial discharge inception voltage, reducing manufacturing costs, and reducing the size of the transverse oil passage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

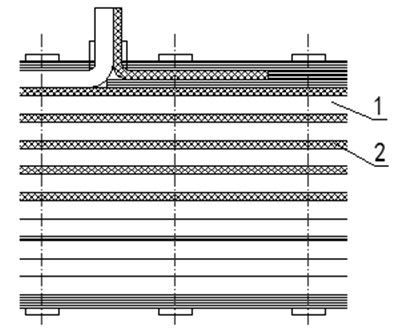

[0009] Accompanying drawing is a kind of specific embodiment of the present invention.

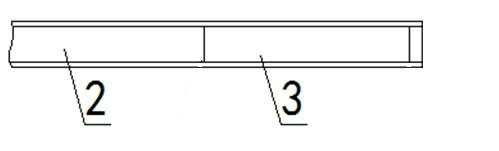

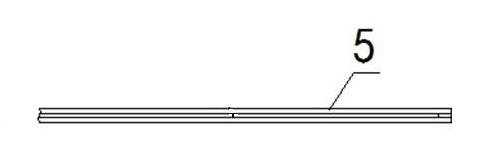

[0010] The insulating structure of the suspension end of the transformer coil inserted into the shielding wire of the present invention includes coil current-carrying wires 1 and coil shielding wires 2 distributed at intervals, the end of the coil shielding wire is connected to the cardboard strip 3, the suspension end of the coil shielding wire 2, the coil shielding wire The outer side of the contact between the wire 2 and the cardboard strip is covered with aluminum metallized crepe paper 5, the outer side of the cardboard strip is wrapped with Denison paper 4, and the floating end of the coil shielding wire 2 is rounded.

[0011] The insulation structure of the suspended end of the transformer coil inserted into the shielding wire includes coil current-carrying wire 1 , coil shielding wire 2 , cardboard strip 3 , Denison paper 4 and crepe paper 5 . The insulating structure of the floati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com