Super-conduction magnetic levitation device without liquid helium volatilization

A magnetic levitation and liquid helium-free technology, which is applied to superconducting magnets/coils, holding devices with magnetic attraction or thrust, household refrigeration devices, etc., can solve the problems of multiple infusions and inability to operate independently for a long time, and achieve reduction Volatile effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

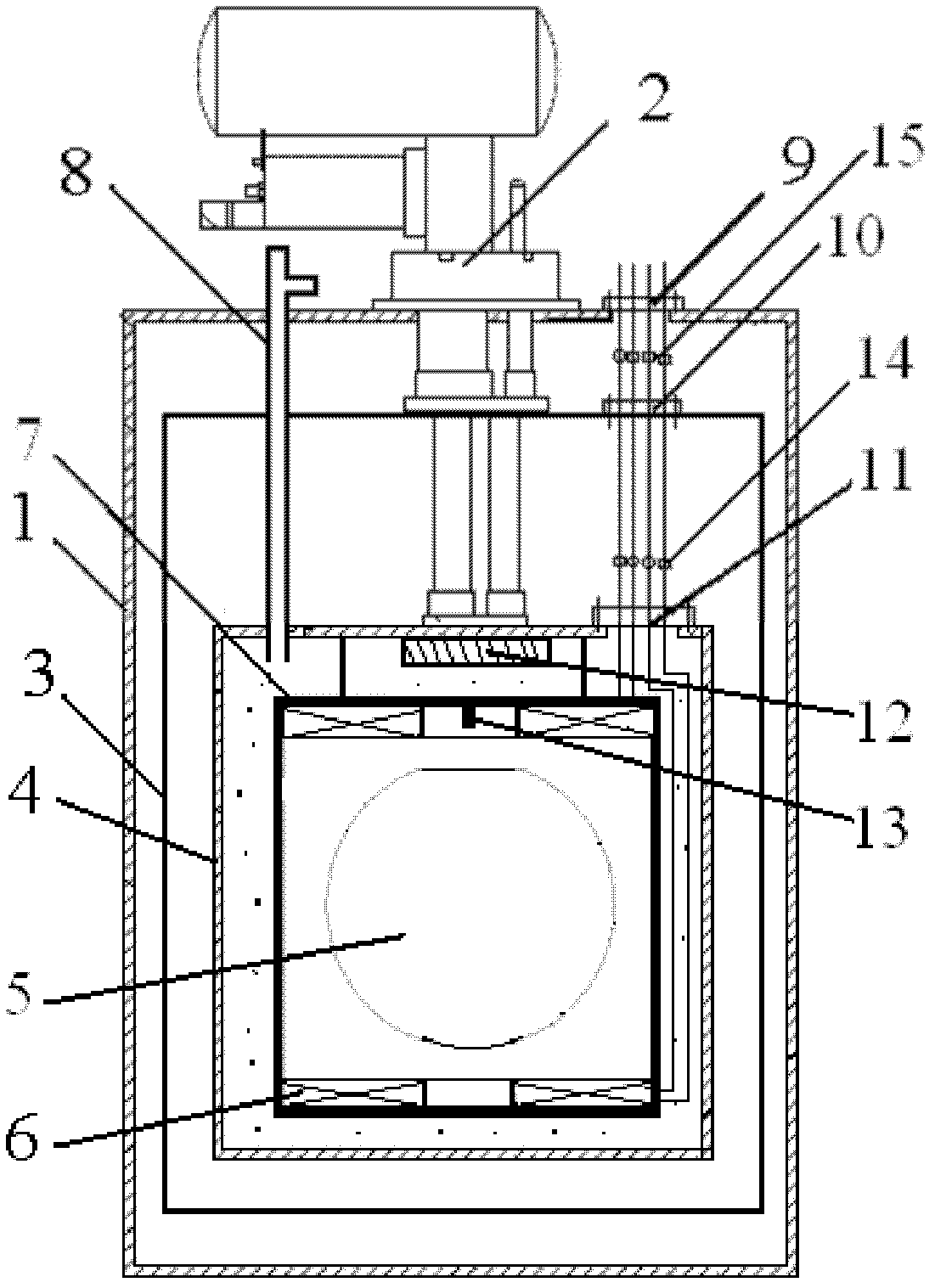

[0014] The device of the present invention comprises a cryogenic container 1, a refrigerator 2, a cold screen 3, a liquid helium container 4, a superconducting rotor 5, a suspension coil 6, a rotor chamber 7, an infusion tube 8, a room temperature current lead joint 9, and a high temperature superconducting current lead joint 10. Low-temperature superconducting current lead connector 11, condenser 12 and polar axis displacement sensor 13. The refrigerator 2 is installed on the upper end of the cryogenic container 4, the superconducting rotor 5 is located in the rotor chamber 7, the suspension coil 6 is arranged at the upper and lower ends of the rotor chamber 7, the condenser 12 is installed at the center above the rotor chamber 7, and the polar axis The displacement sensor 13 is installed at the top center of the superconducting rotor 5 inside...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com