In-wheel motor drive device

An in-wheel motor and driving device technology, which is applied to electric power devices, gear transmission devices, electro-mechanical devices, etc., can solve the problems such as the need for cooling water, the increased weight of the in-wheel motor driving device, and the deterioration of the followability of the suspension device, so as to improve the ride quality. Comfort performance, effect of reducing unsprung weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

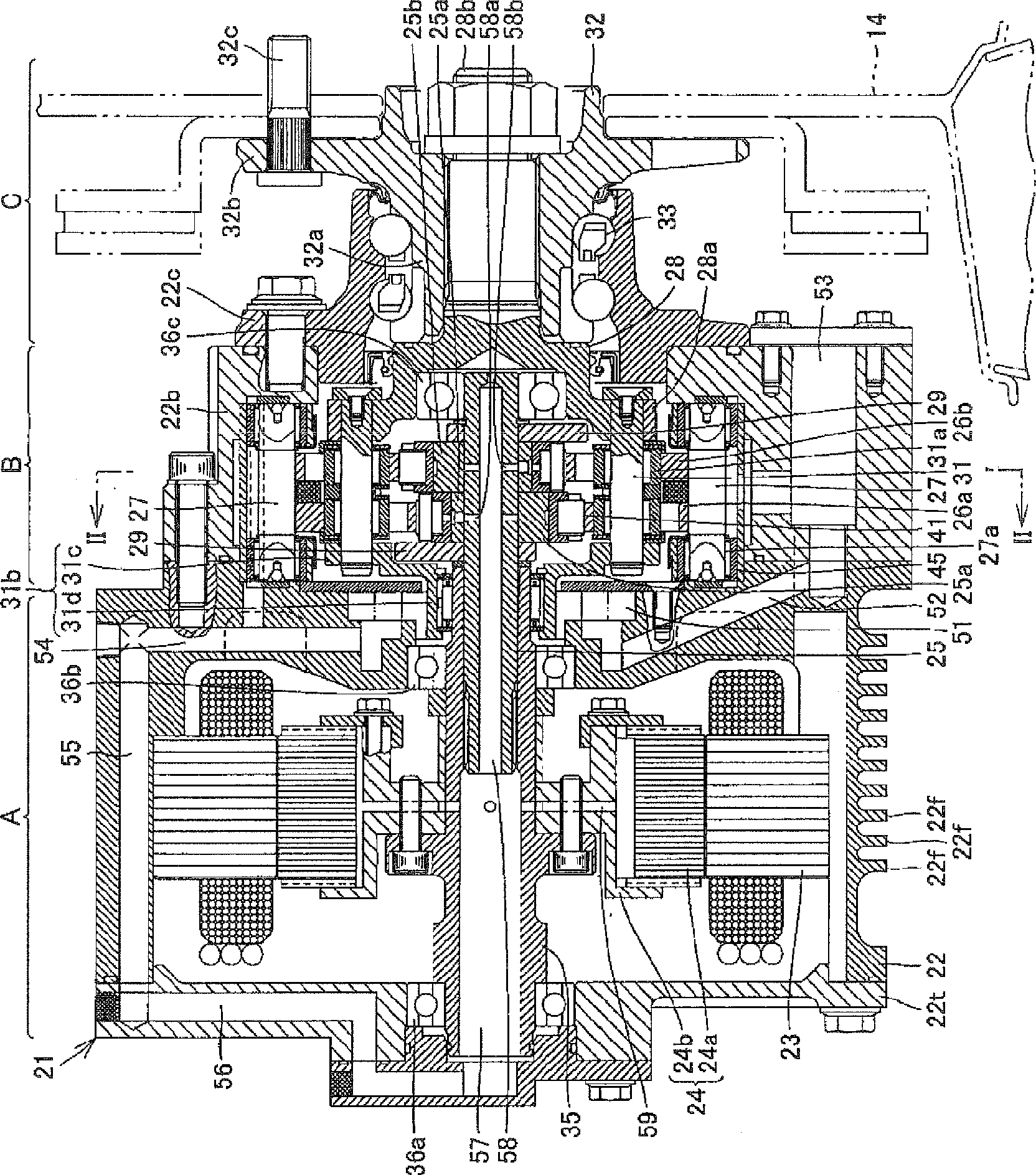

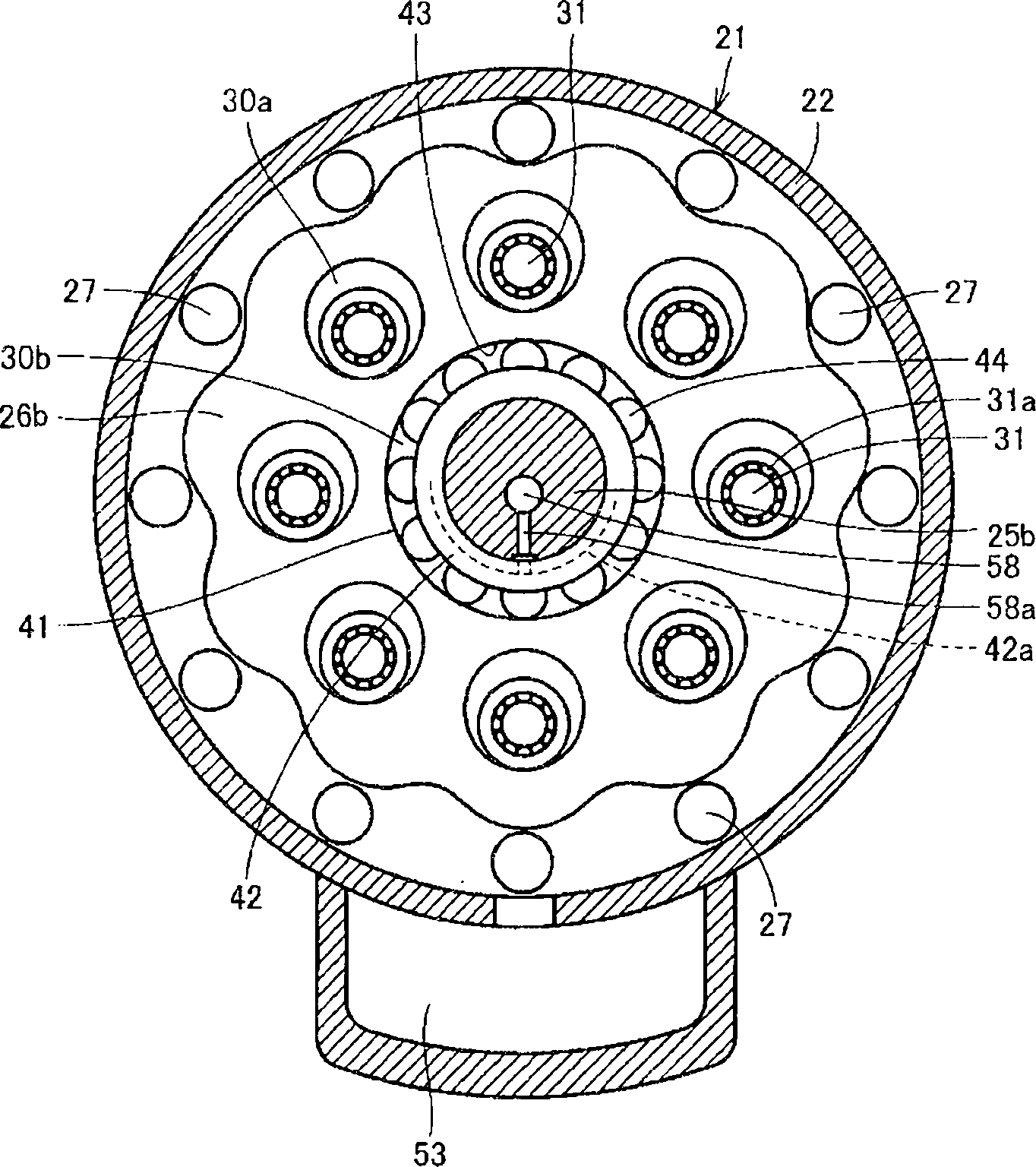

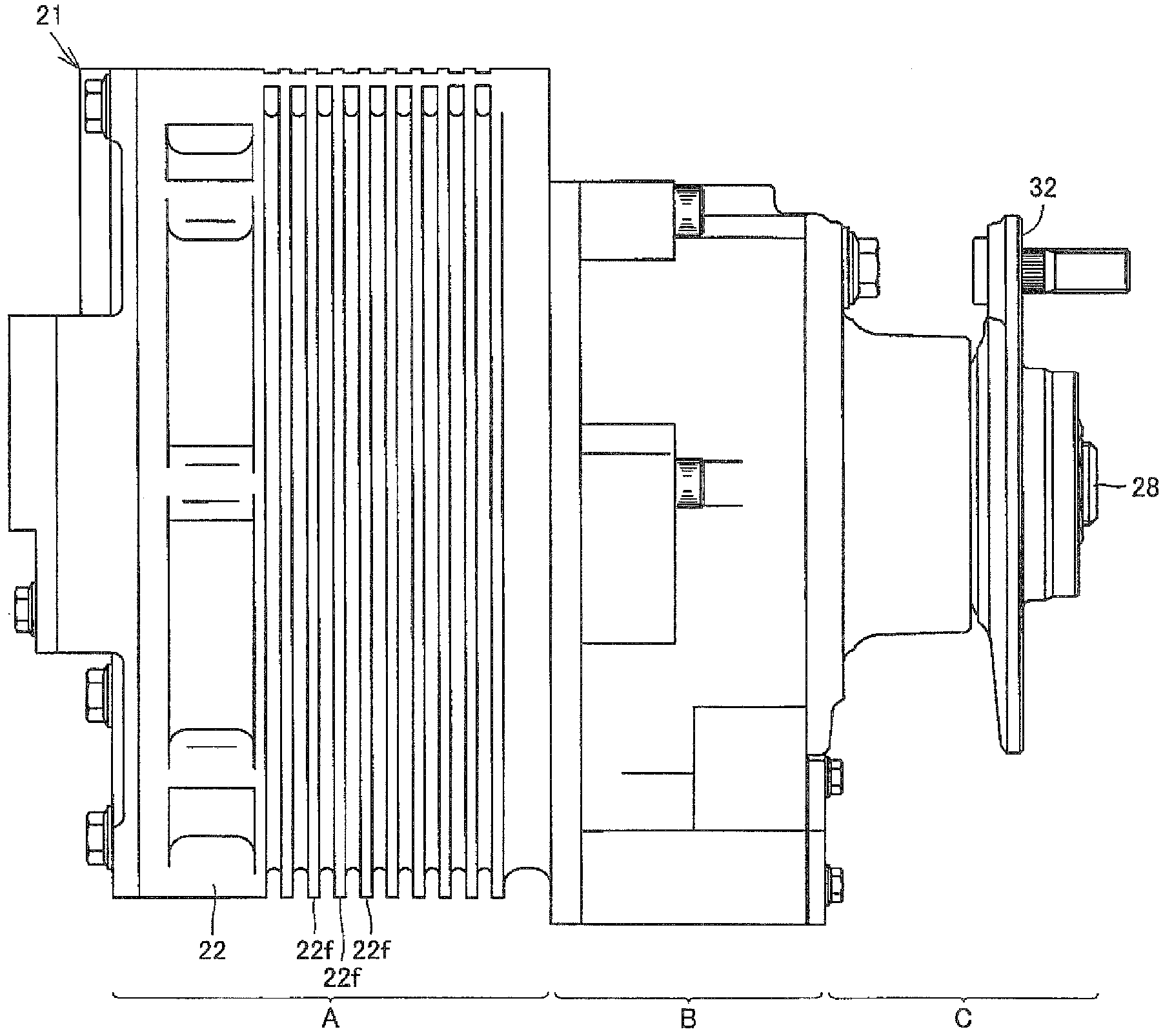

[0038] Hereinafter, embodiments of the present invention will be described in detail based on examples shown in the drawings. figure 1 It is a longitudinal sectional view showing the in-wheel motor driving device as the first embodiment of the present invention. figure 2 yes figure 1 Sectional view of II-II. image 3 yes figure 1 Side view of an in-wheel motor drive unit. Figure 4 is viewed from the axis figure 1 Front view of the in-wheel motor drive unit. Figure 5 is has figure 1 A top view of an in-wheel motor drive unit for an electric vehicle. Image 6 yes Figure 5 Rear sectional view of an electric motor vehicle.

[0039] refer to Figure 5 , The electric vehicle 11 has: a chassis 12; a front wheel 13 as a steering wheel; a rear wheel 14 as a driving wheel; refer to Image 6 The rear wheel 14 is housed inside the wheel house 12a of the chassis 12, and is fixed to the lower portion of the chassis 12 via a suspension device (suspension) 12b.

[0040] The su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com