Connection assembly for a sensor assembly and sensor assembly

A sensor device and connection device technology, applied in the direction of measuring devices, instruments, measuring instrument components, etc., can solve the problems of excessive injection molding, difficult positioning, increased mold wear, etc., and achieve the effect of rapid positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

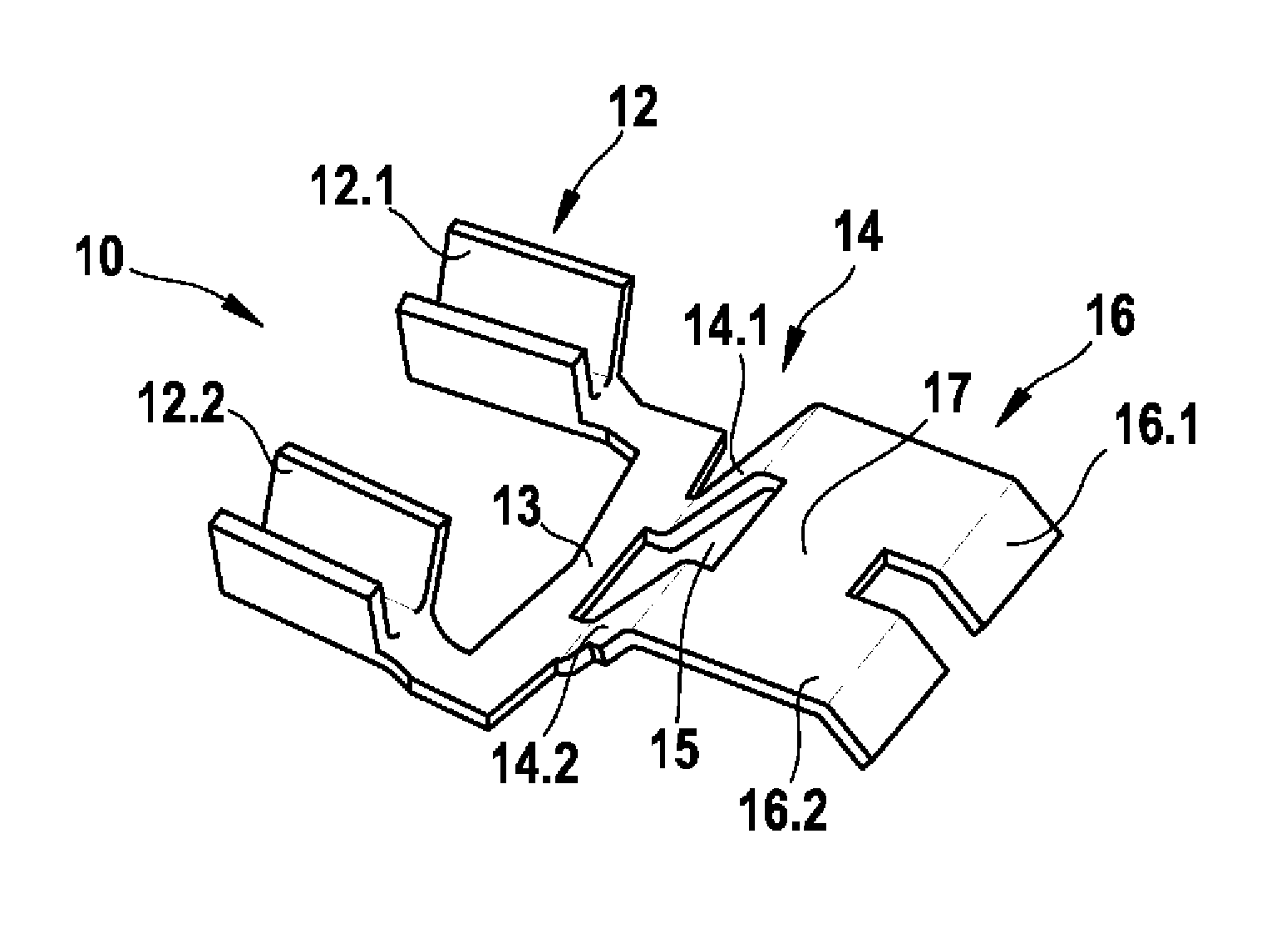

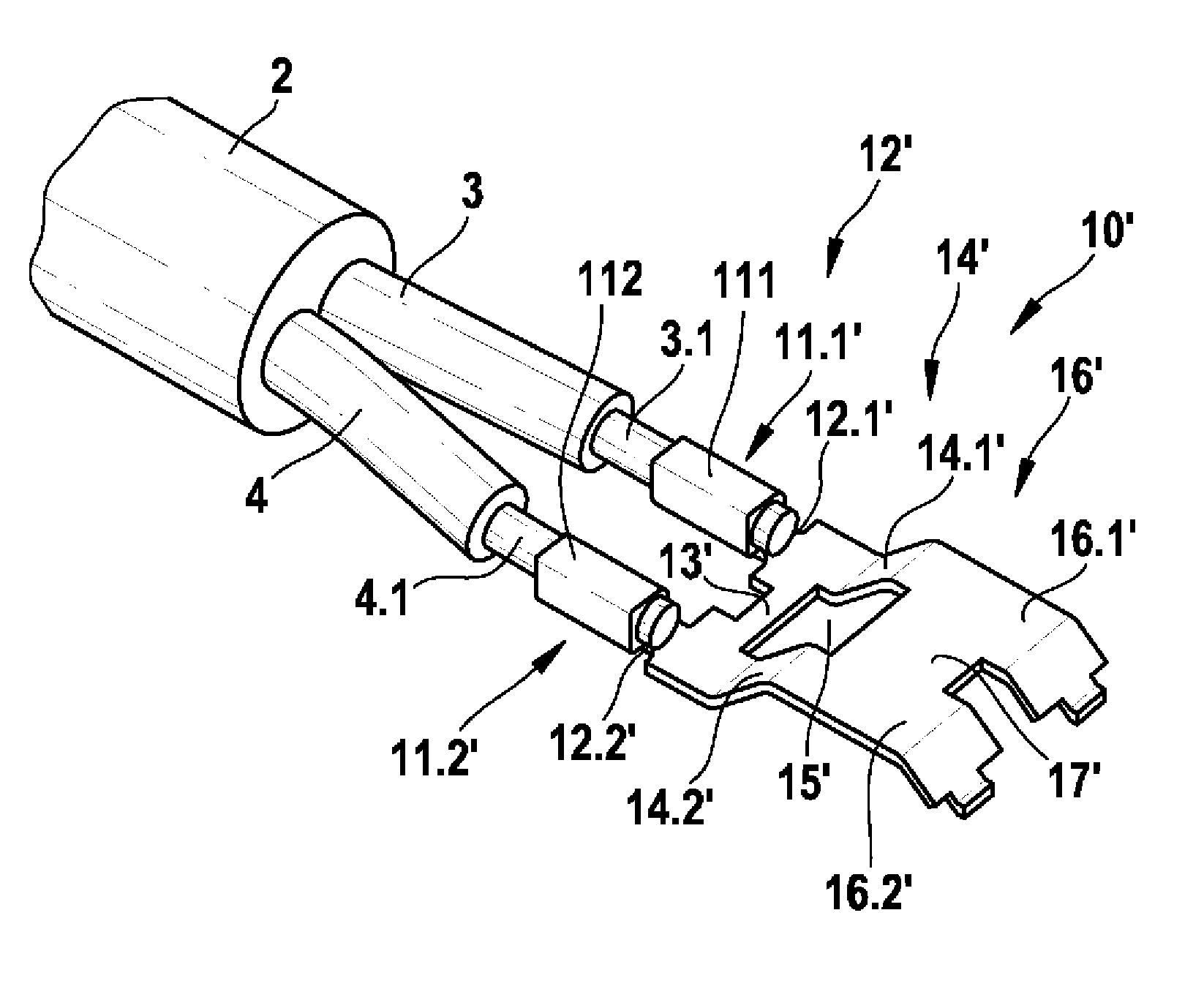

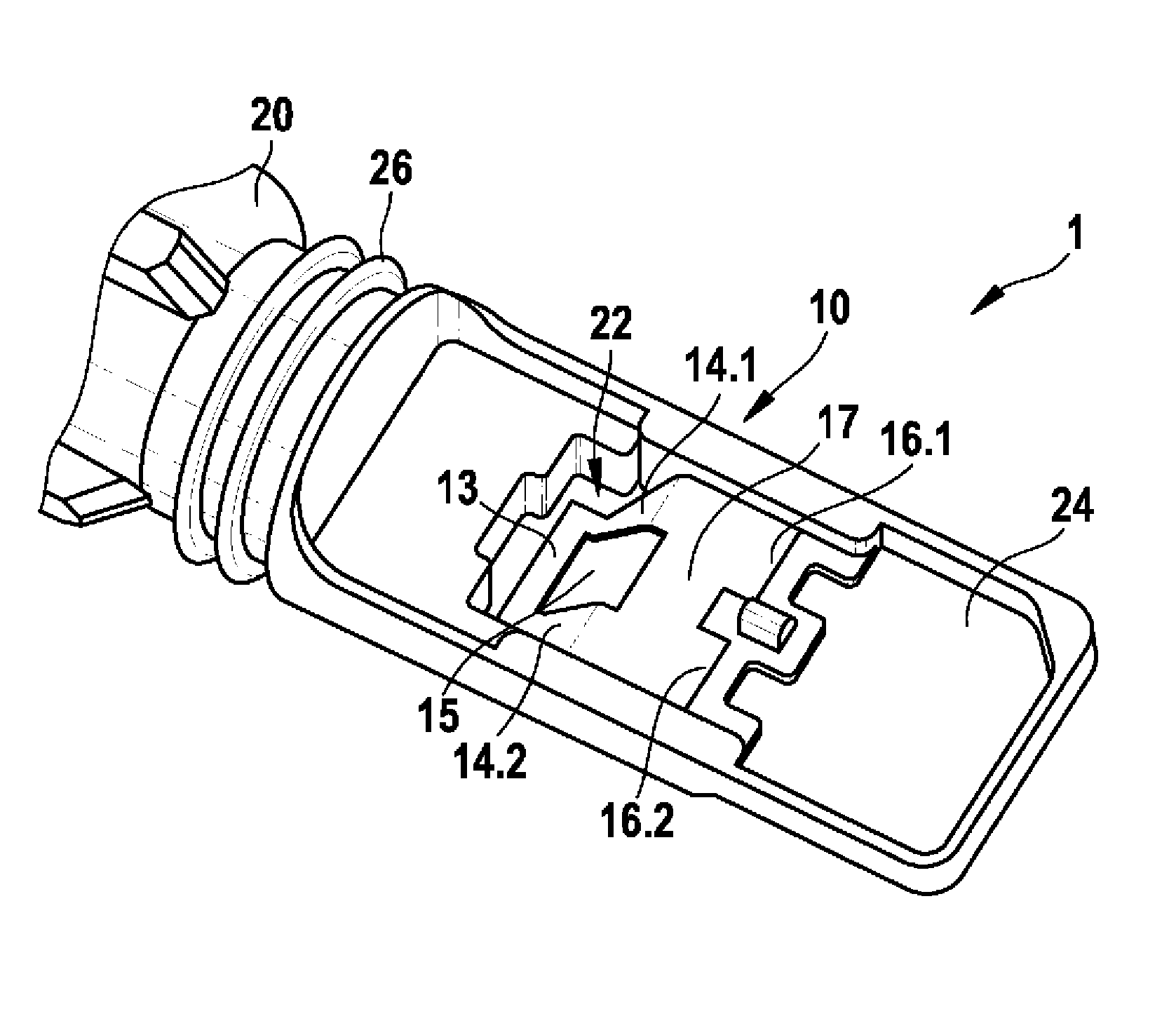

[0022] figure 1 and 2 A schematic perspective view of a first exemplary embodiment of a connecting element 10 is shown in each case for use in image 3 and 4 A connection device 1 for a sensor device according to the invention is shown in FIG. here, figure 1 The connection element 10 is shown before it is connected with a two-wire connection cable 2, and figure 2 The connection element 10 is shown after the double crimped connection structure 11.1, 11.2 has been created with the two-wire connection cable 2.

[0023] as available from figure 1 As seen in or 2, the first embodiment of the connecting element 10 comprises in the first contact region 12 two first connecting parts 12.1, 12.2 embodied as curled shoulders, the first connecting part 12.1 , 12.2 are connected to each other through the first connecting piece 13 . as especially available from figure 2As seen in , the two first connectors 12.1, 12.2 are electrically and mechanically connected to the core wires 3,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com