Variable-track single-axle excitation vibrator

A vibrator, variable technology, applied in the direction of the fluid that utilizes vibration, can solve the problems of many institutional consumables, error-prone, and inconvenient adjustment of the direction angle, etc., to achieve the adjustment of the vibration direction angle, convenient use and maintenance, and screening ideal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

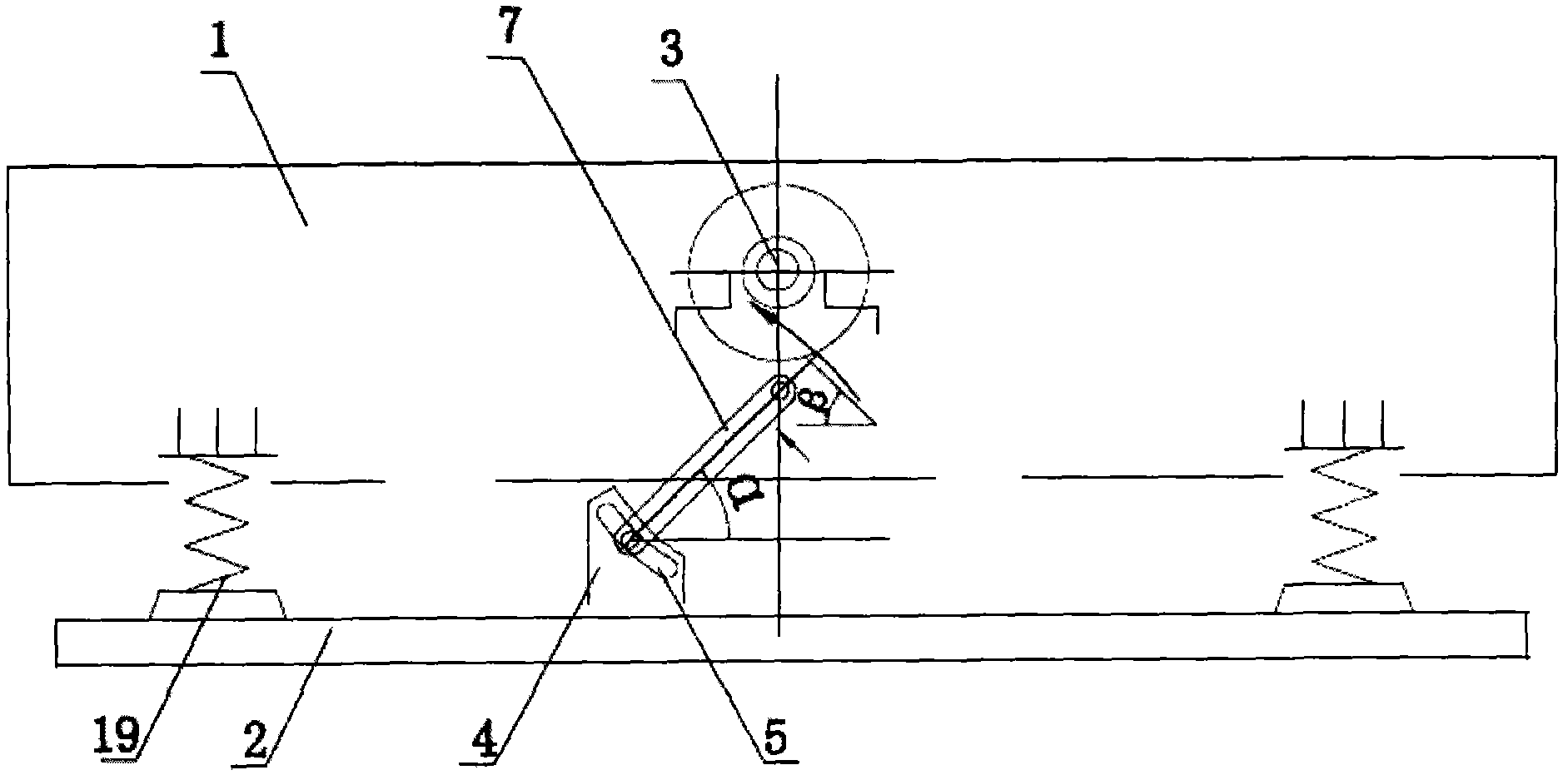

[0044] Embodiment 1: as figure 1 As shown, a single-axis variable trajectory vibrator includes a vibration box 1, a base 2 and an excitation shaft 3. The vibration axis 3 is arranged on the vibration box 1, and the vibration box 1 and the base 2 Buffer springs 19 are arranged on the four corners.

[0045] Between the vibration box 1 and the base 2, there is also an obliquely arranged rail 7. The rail 7 is a pair and symmetrically arranged on both sides of the vibration box 1. The length of the rail 7 is non-adjustable. fixed rod.

[0046] The hinge shaft between the lower end of the track rod 7 and the base 2 is arranged in the arc slot 5 and locked by the adjusting nut; the arc slot 5 is arranged on the base 4, and the base 4 is arranged on the base 2.

[0047] The rail-fixing rod 7 is arranged perpendicular to the fixed axis of the excitation shaft 3, and the hinge shaft between the upper end of the rail-fixing rod 7 and the vibration box 1 is arranged on the longitudinal...

Embodiment 2

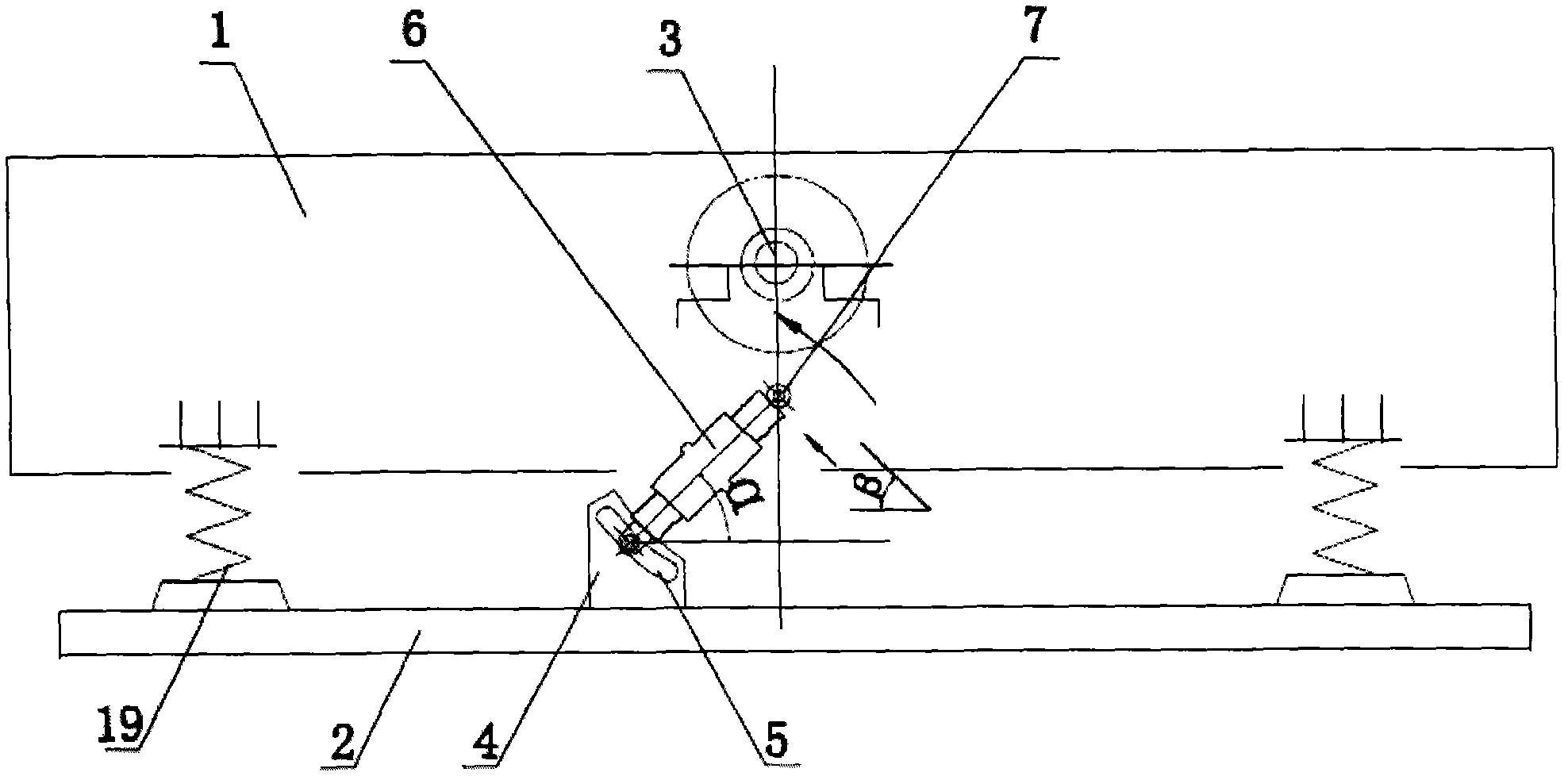

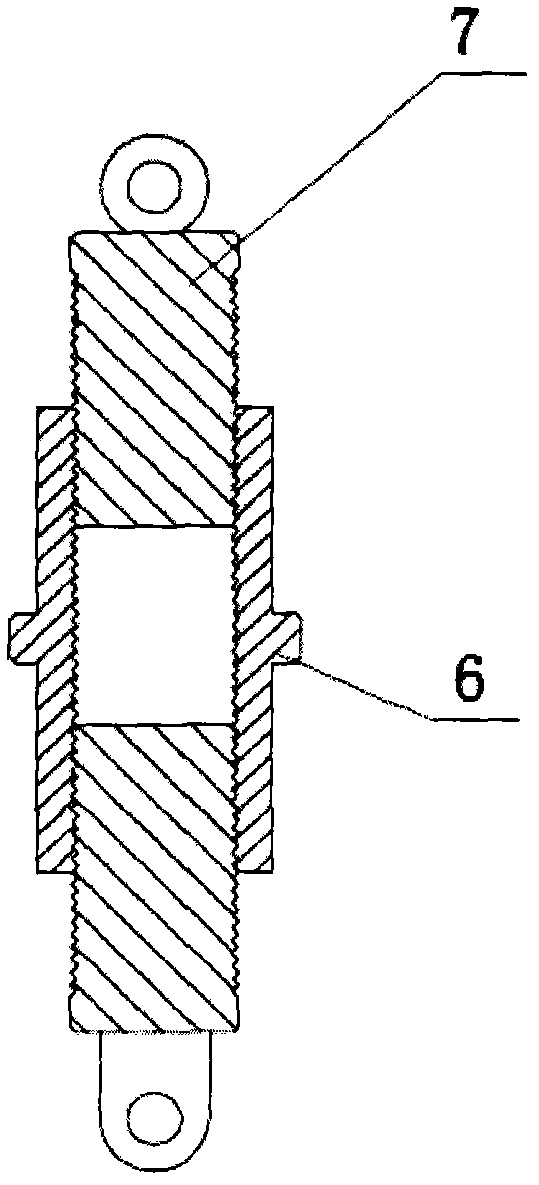

[0048] Embodiment 2: as figure 2 and image 3 As shown, a single-axis variable trajectory vibrator includes a vibration box 1, a base 2 and an excitation shaft 3. The vibration axis 3 is arranged on the vibration box 1, and the vibration box 1 and the base 2 Buffer springs 19 are arranged on the four corners.

[0049] Between the vibrating box 1 and the base 2 there is also an obliquely arranged rail-fixing rod 7 , which is a pair of rail-fixing rods 7 arranged symmetrically on both sides of the vibrating box 1 .

[0050] The rail-fixing rod 7 is the screw mandrel with the opposite thread direction of two sections separated, and the two-section rail-fixing rod 7 is connected together by the screw sleeve 6;

[0051] The hinge shaft between the lower end of the track rod 7 and the base 2 is arranged in the arc slot 5 and locked by the adjusting nut; the arc slot 5 is arranged on the base 4, and the base 4 is arranged on the base 2.

[0052] The rail-fixing rod 7 is arranged ...

Embodiment 3

[0053] Embodiment 3: as Figure 4 As shown, the upper end of the rail fixing rod 7 is sheathed in the sliding sleeve 8, and the sliding sleeve 8 is hinged on the vibration box 1. The lower end of the track rod 7 is hinged on the base 2.

[0054] All the other are with embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com