Pickup device of numerical control variable-pitch sorting machine

A picking device and sorting machine technology, applied in sorting and other directions, can solve the problems of high requirements for incoming materials, material picking that cannot be randomly spaced, and large limitations, so as to improve production efficiency, promote value, and structure. reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] Below in conjunction with accompanying drawing, the present invention will be described in further detail:

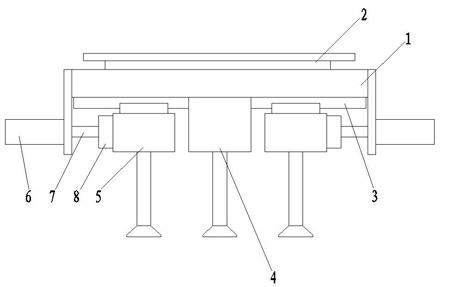

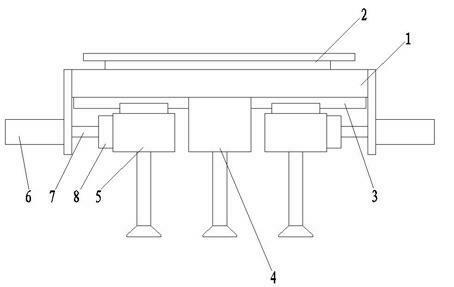

[0009] Referring to the accompanying drawings, a pick-up device for a numerically controlled variable-distance sorter of the present invention includes a base plate 1 and a pick-up head. The outside of the base plate 1 is fixed to the main rail 2 arranged horizontally; The middle position of the fixed pick-up head 4 is fixed; the left and right sides of the fixed pick-up head 4 are respectively provided with a movable pick-up head 5 installed on the auxiliary guide rail 3; the left and right sides of the substrate 1 are respectively fixed with a horizontal micro-stepping motor 6 ; The output shaft of the miniature stepping motor 6 is fixedly connected with the ball screw 7 arranged horizontally; the ball screw 7 is covered with a screw nut 8 that cooperates with each other;

[0010] The working method of the present invention is as follows: the sorting machine de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com