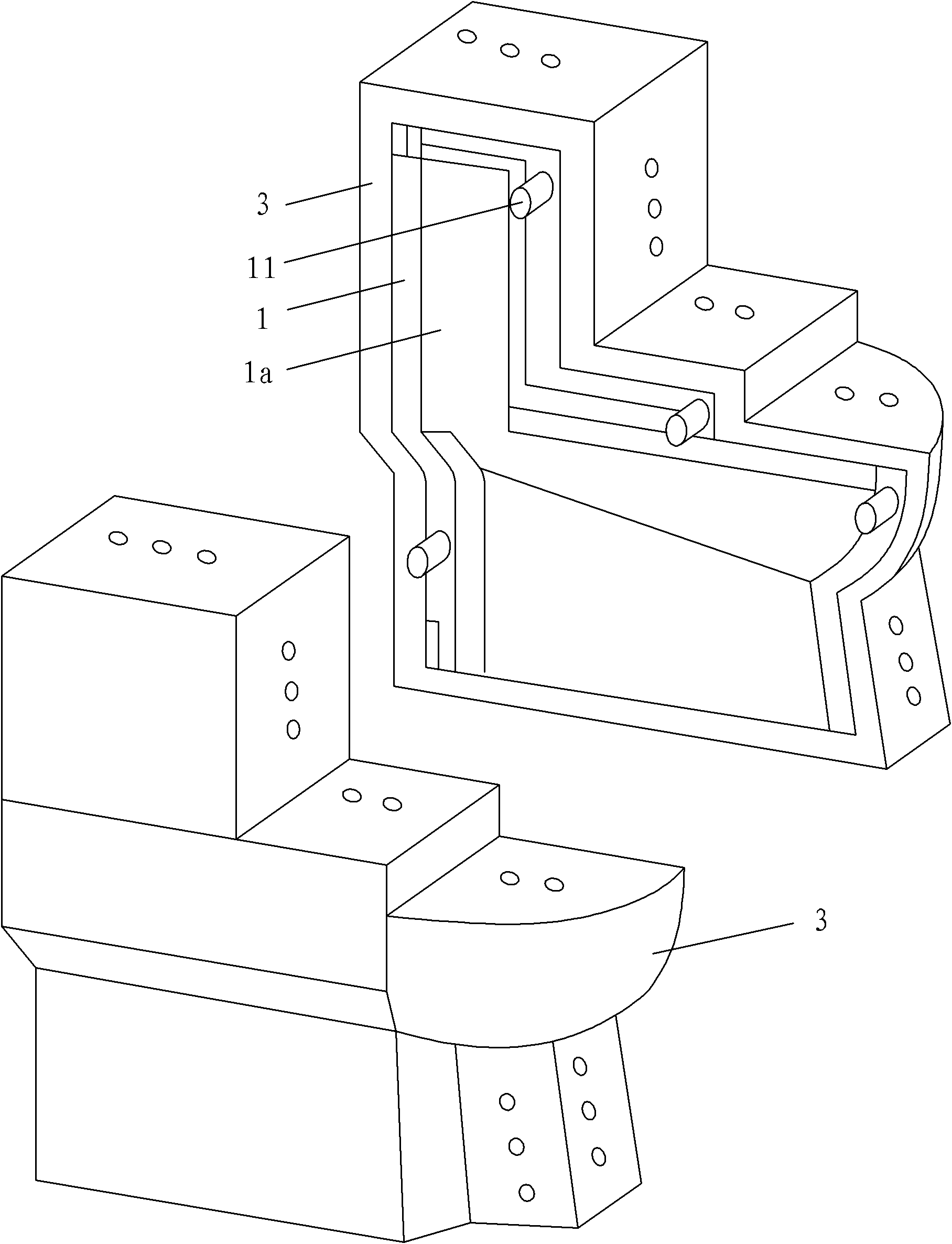

Low-pressure quick drainage mold and method for manufacturing same

A mold and low pressure technology, applied in the field of low pressure fast drainage mold and its preparation, can solve the problems of low preparation efficiency and production efficiency, long drying time of gypsum mold, long preparation cycle, etc., achieve high-efficiency drainage effect, shorten preparation cycle, The effect of shortening the drain time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

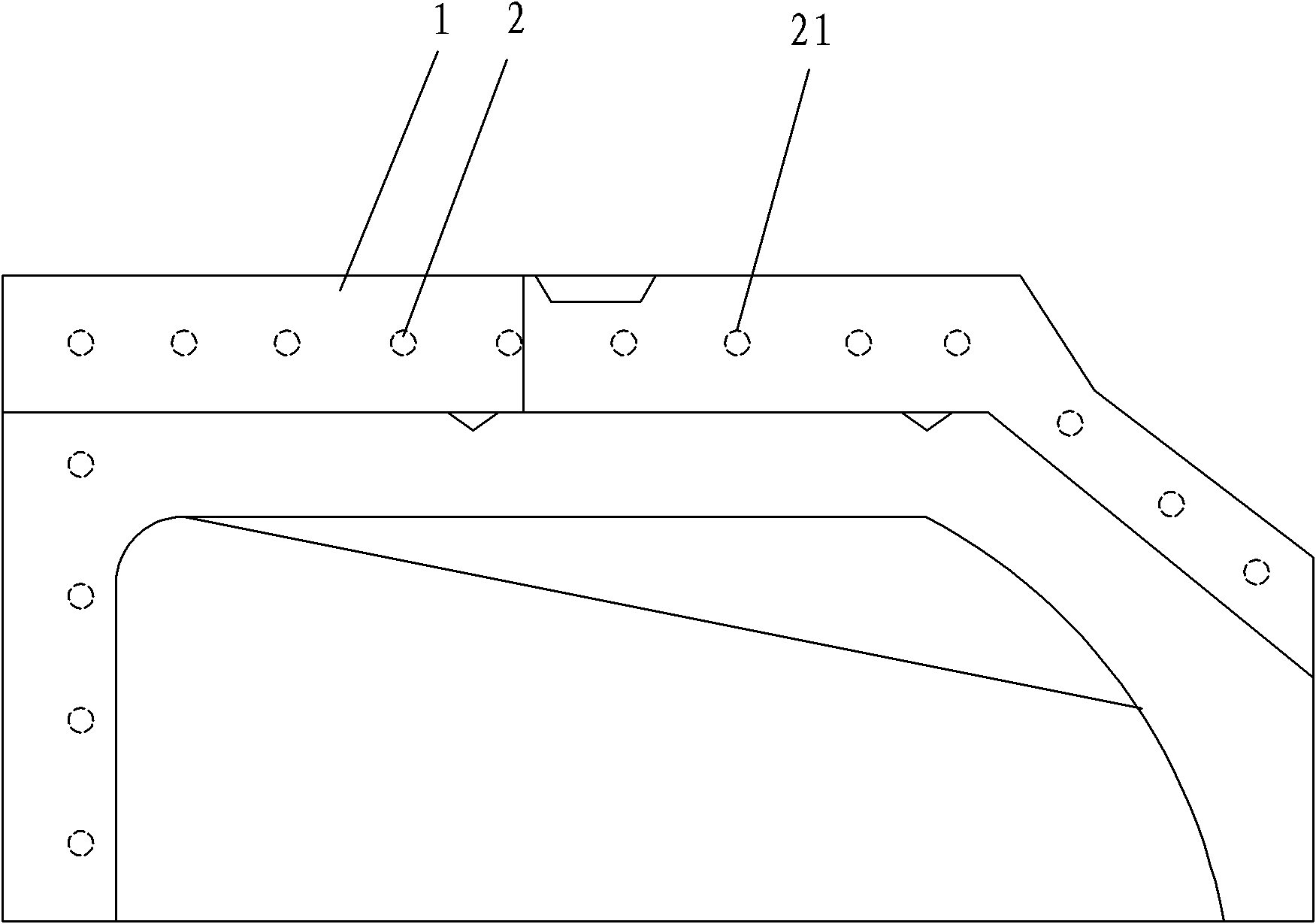

Embodiment 1

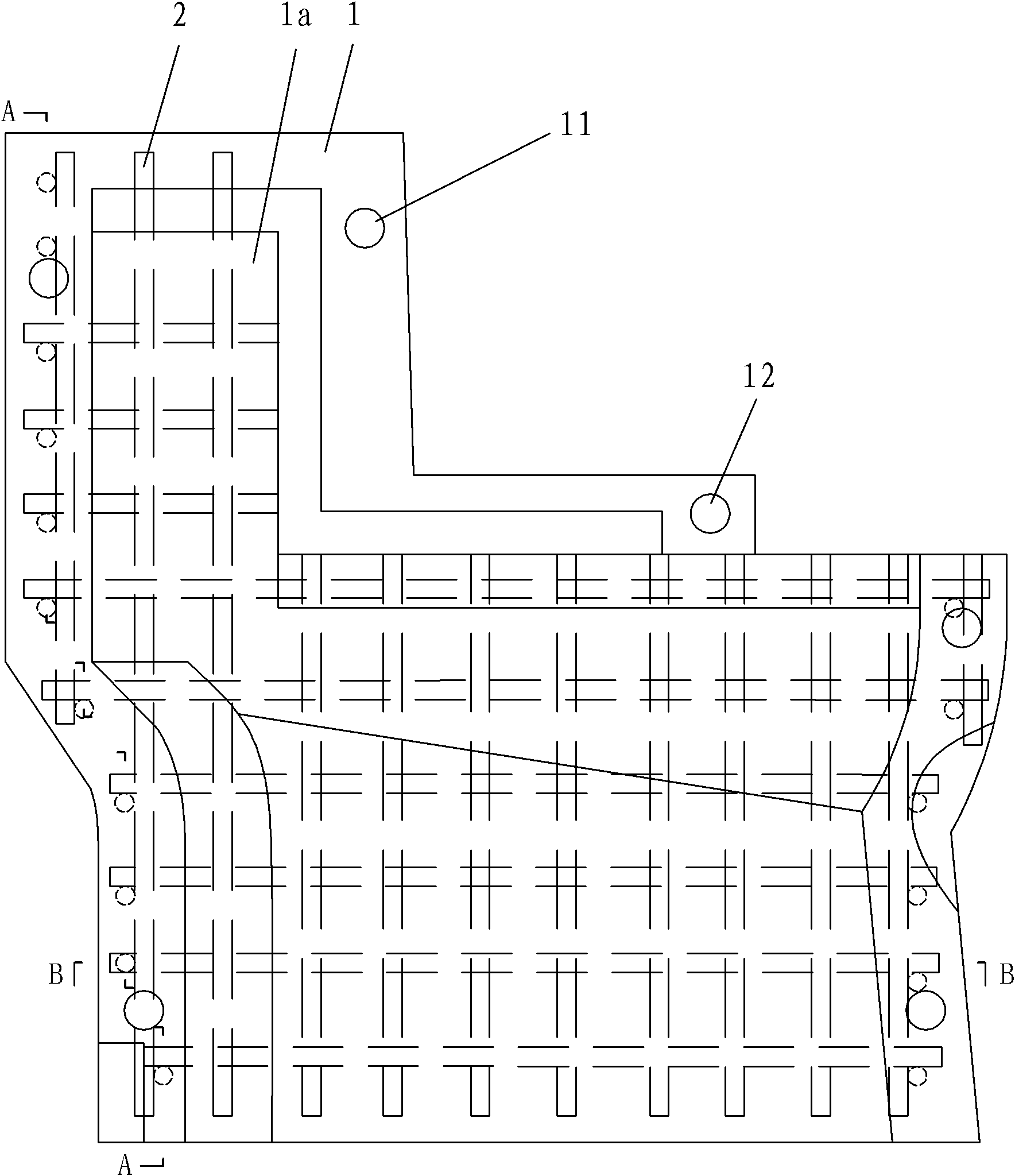

[0052] Use the above steps 1 to 5 to prepare the toilet mold. In the step 2 of erecting the rod net, the horizontal thin rods 4 are arranged at equal distances, and the longitudinal thin rods 4 and the thin rods 4 are evenly distributed on the horizontal thin rods 4 The diameter of the rods is 6mm, and the distance between the thin rods 4 ranges from 60mm to 80mm. In this way, it is convenient to lay the rod net 5 on the half master mold 3 and improve the efficiency of preparing the plaster half mold 1.

Embodiment 2

[0054] The above steps 1 to 5 are used to prepare a toilet mold. In the step 2 of erecting the rod net, the thin rods 4 are arranged horizontally, and the longitudinal thin rods 4 are pasted on the horizontal thin rods 4.

[0055] The main difference between this implementation and implementation one is the spacing of the thin rods 4. The spacing between the horizontal and vertical thin rods 4, and the spacing between the horizontal or vertical thin rods 4, is closer to the center of the female mold half 3 than at the periphery of the female mold half 3. In this way, the plaster half mold 1 formed by turning over the half master mold 3 has a more efficient and rapid drainage function.

Embodiment 3

[0057] The above steps 1 to 5 are used to prepare the toilet mold. In the step 2 of erecting the rod net, the thin rods 4 are arranged horizontally, and the longitudinal thin rods 4 are pasted on the horizontal thin rods 4.

[0058] The main difference between this implementation and implementation one lies in the spacing of the thin rods 4, the spacing between the horizontal and vertical thin rods 4, the horizontal or longitudinal thin rods 4, and the spacing in the deeper part of the cavity of the half master mold 3 is smaller than that of the half master mold 3. The distance between the shallow parts of the cavity. In this way, the plaster half mold 1 formed by turning over the half master mold 3 also has a more efficient and rapid drainage function.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap