Design method for rear combination headlamps of passenger car

A design method and technology for passenger cars, applied in vehicle components, optical signals, signal devices, etc., can solve problems such as poor illumination, poor water drainage, and difficulty in maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

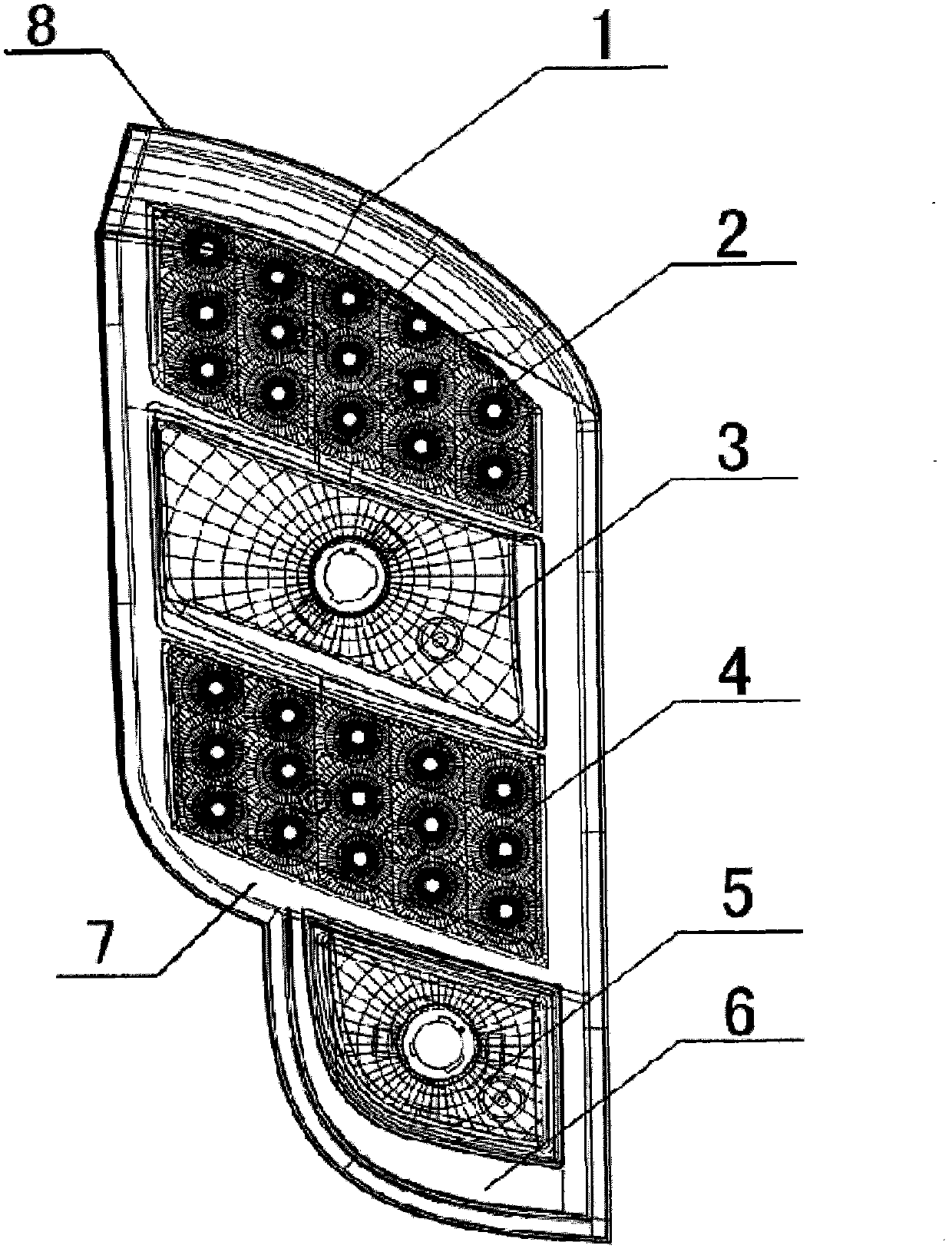

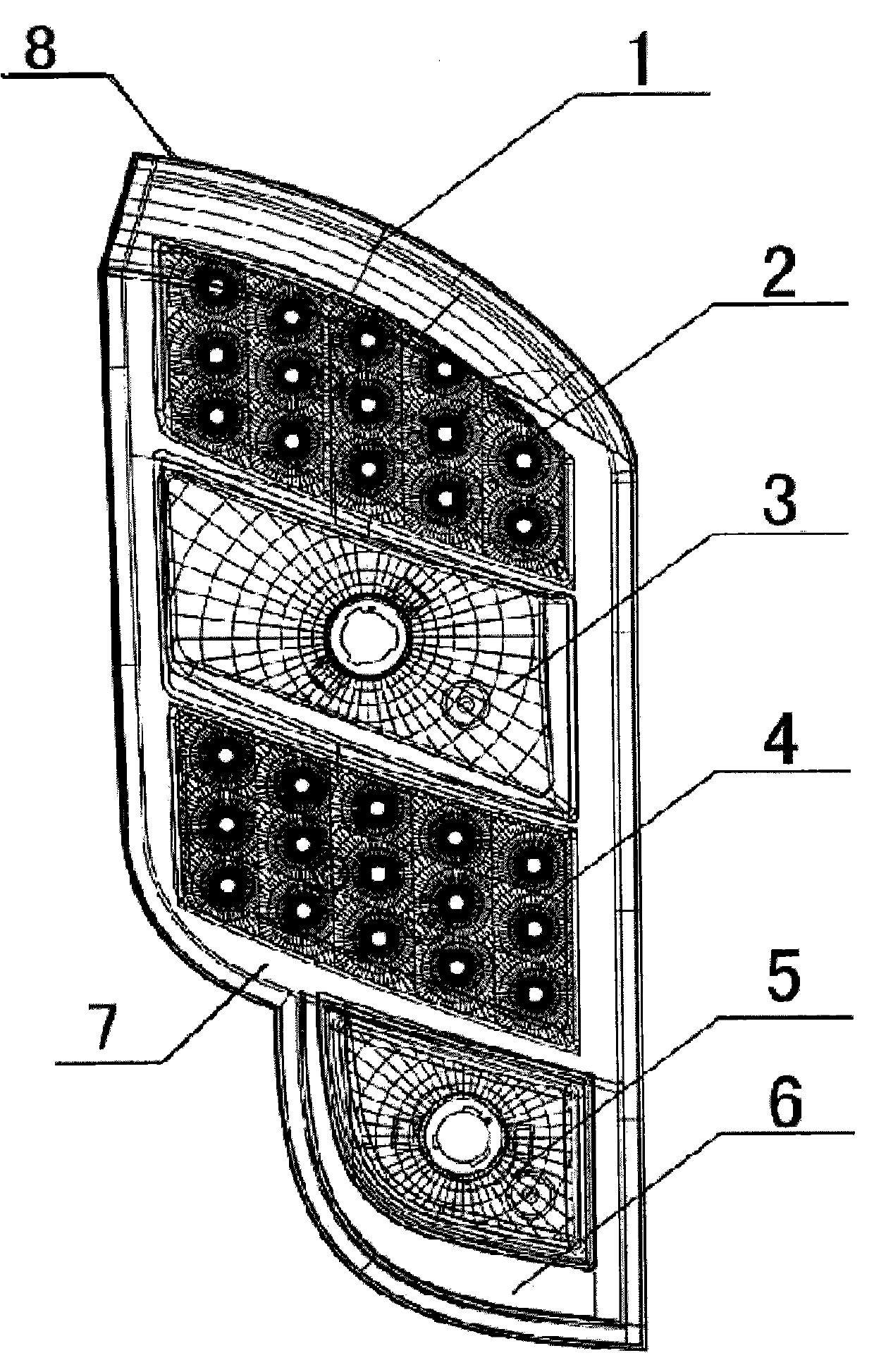

[0012] Example 1 as figure 1 As shown, the rear combination headlight of a passenger car includes a base 1, a position light 2, a turn signal 3, a brake light 4, a reversing light 5, a reflector 6 and a lampshade 7, and it is characterized in that: the base 1 is from top to bottom The position lamp 2, the turn signal lamp 3, the brake lamp 4 and the reversing lamp 5 are successively installed on the lower part, and the lampshade 7 covers the position lamp 2, the turn signal lamp 3, the brake lamp 4 and the reversing lamp 5 inside. Two trapezoidal buckles are respectively provided on both sides of the edge of the base 1 , the lampshade 7 is connected to the base 1 through buckles and glue strips 8 are pasted at the seams, and the reflector 6 is also fixed on the lampshade 7 .

Embodiment 2

[0013] The difference between Embodiment 2 and Embodiment 1 is that the reflector 6 is composed of many radial curved surfaces, and the curvature of the curved surface gradually changes from the middle of the lamp to the edge, and the curved surface at the edge is 30° from the vertical surface of the side, which can reduce the light Loss, increased light intensity, integral molding of the reflector.

[0014] At the same time, in order to solve the problems of complex installation and difficult maintenance of the existing rear lights, the position lights 2, the turn lights 3, the brake lights 4, and the reversing lights 5 are combined on the base 1, and the development base of the injection mold is used. At the same time, each light The wires pass through the same rubber tube, the direction of the wire harness is unified, and the branch of the wire harness is reduced, which is convenient for wiring and line maintenance, and ensures the safety of the line. The base 1 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com