Intelligent automatic dosing control system

An automatic control system and intelligent batching technology, applied in the direction of conveyor control devices, conveyor objects, transportation and packaging, etc., can solve the problems of stability and weighing results, and achieve the effect of strong automation and high batching accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

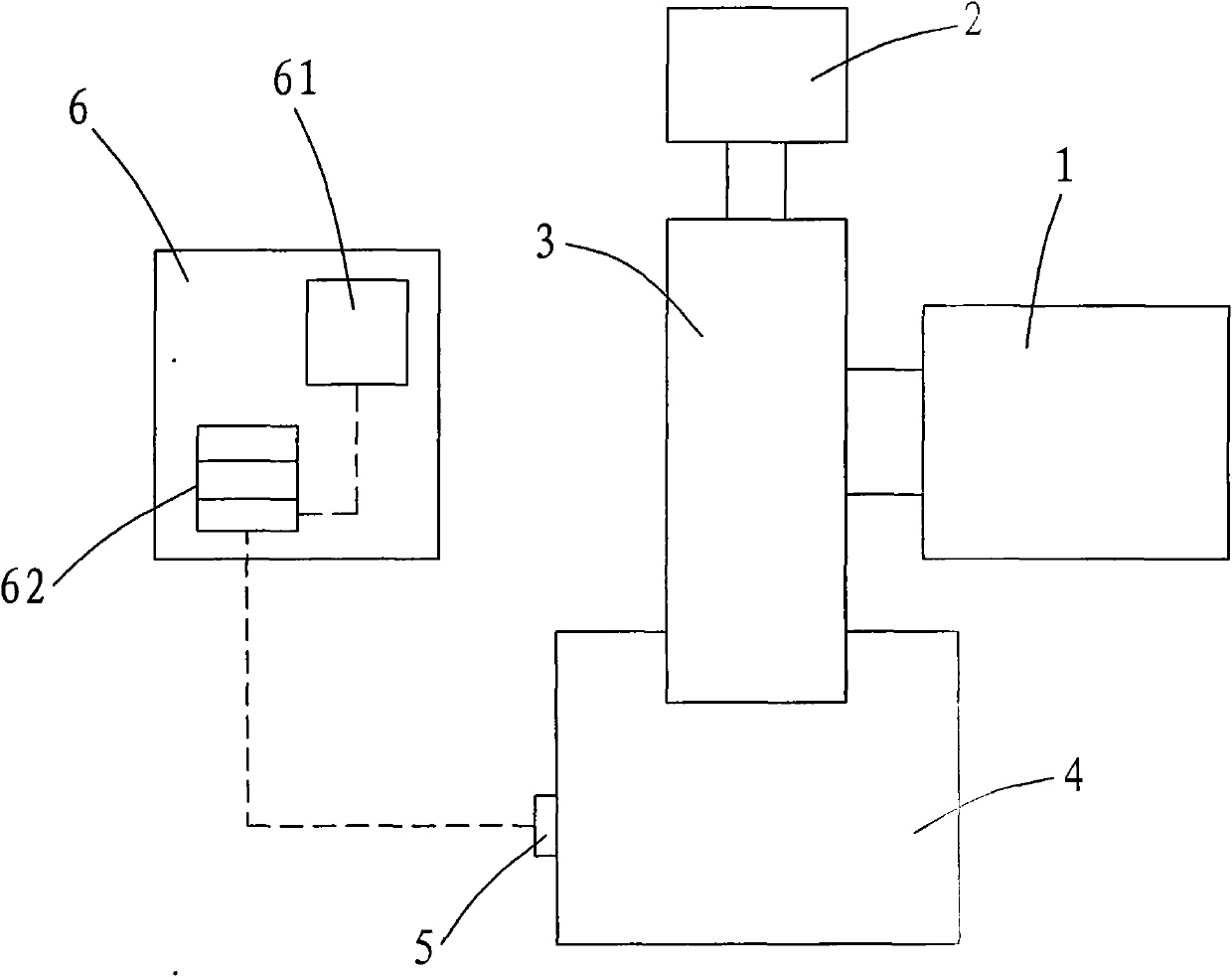

[0012] Such as figure 1 As shown, an intelligent batching automatic control system includes a hopper 1, a motor 2, a feeder 3, a weighing hopper 4, a weighing sensor 5 and a weighing instrument 6, and the weighing sensor 5 is located at the bottom of the weighing hopper 4, The weighing instrument 6 is provided with a weight setting module 61 , the feeder 3 is driven by the motor 2 , and the start of the motor 2 is controlled by the weight setting module 61 .

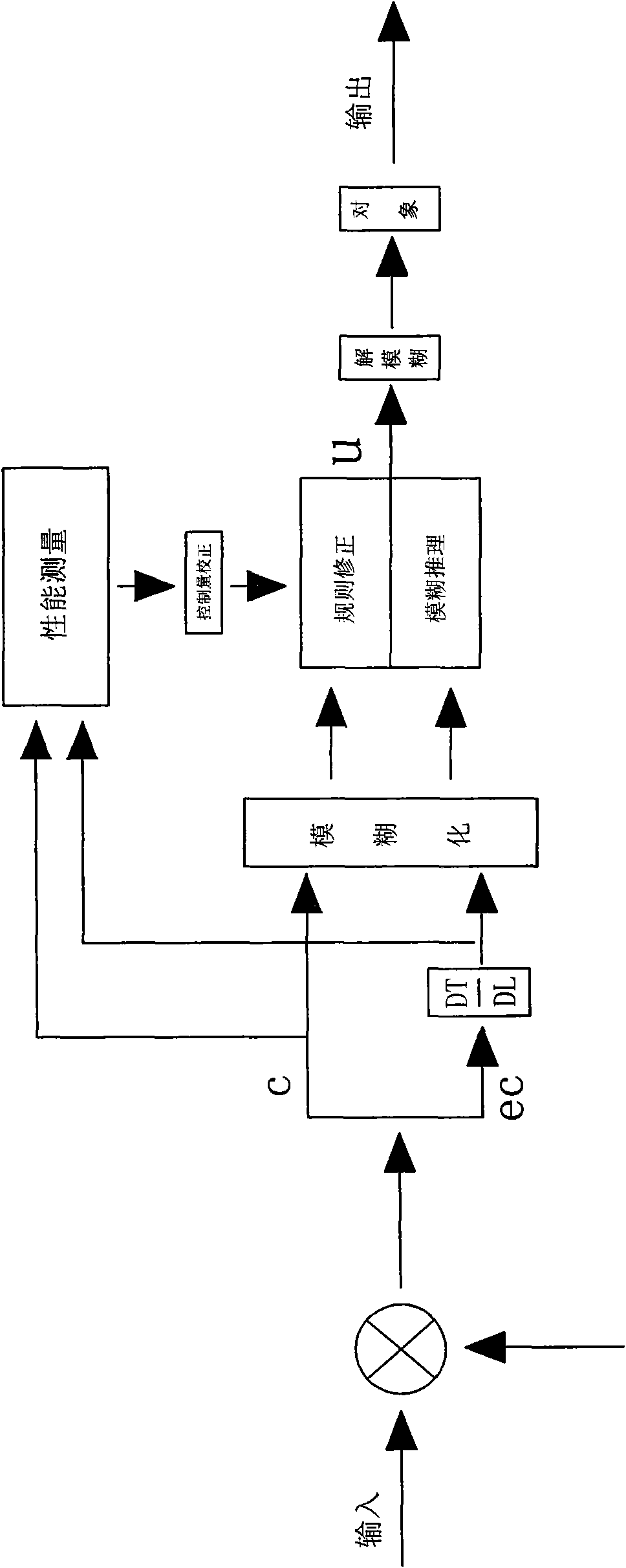

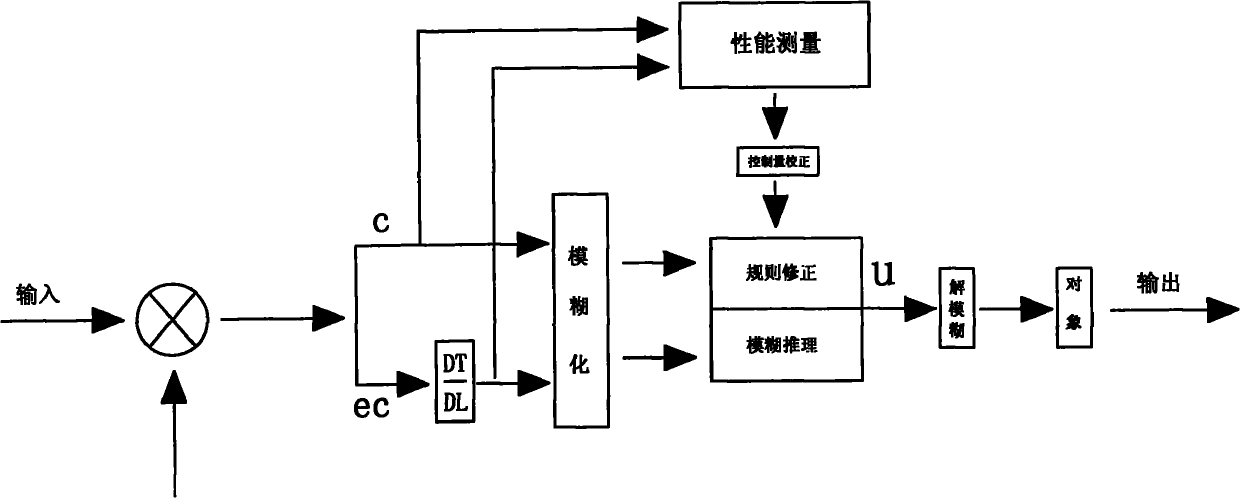

[0013] The weighing instrument 6 is also equipped with a fuzzy self-adaptive controller 62. The quality of the fuzzy control depends on the selection of the fuzzy self-adaptive controller and the establishment of fuzzy rules. This system adopts the model of double input and single output. The deviation e and the deviation change rate ec are used as the input variables of the fuzzy adaptive controller, and the output frequency u of the frequency converter is used as the output variable. For its specific control process, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com