Rolled steel plate tensioning device for rolled steel plate rolling and unrolling machine

A technology of tensioning device and steel coil, which is applied in the directions of coiling strips, transportation and packaging, and thin material processing, etc., which can solve the problems of large space occupied by steel coils, no anti-loosening device, and large space occupied by steel coils. Achieve the effects of reduced space occupation, easy transportation and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

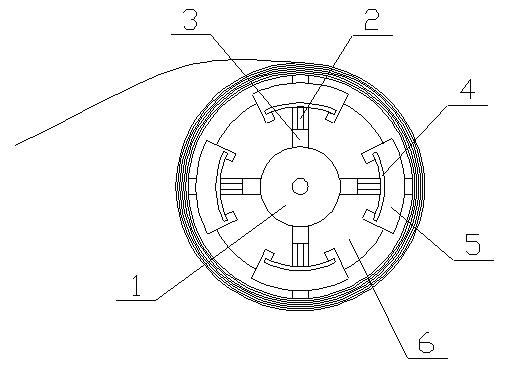

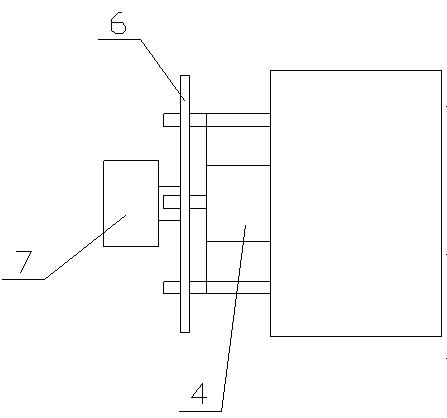

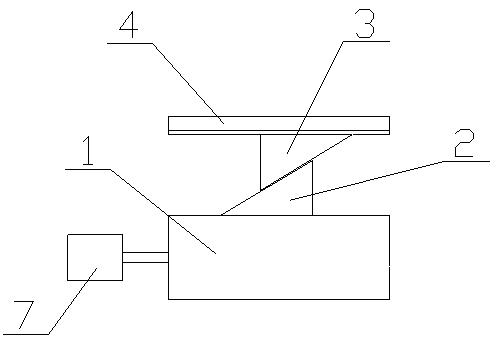

[0013] The steel plate coil tensioning device of the steel plate coil retracting and unwinding machine mainly includes a main shaft 1, a lower triangular block 2, an upper triangular block 3, a support plate 4, a tensioning block 5, a turntable 6 and a cylinder 7, and it is characterized in that: the main shaft 1 is fixed A lower triangular block 2 is provided, and an upper triangular block 3 is arranged on the lower triangular block 2, wherein the lower triangular block 2 and the upper triangular block 3 are concave-convex sliding fit, and the upper triangular block 3 is fixedly connected to the support plate 4, and on the support plate 4 is fixed with a tension block 5 by screws, one end of the support plate 4 is fixedly connected to the turntable 6, and one end of the main shaft 1 is connected to the cylinder 7.

[0014] Bolts are arranged on the tension block 5 .

[0015] The numbers of the upper triangular block 2, the lower triangular block 3, the support plate 4 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com