Self-lifting mounting platform for steel head material hoister and mounting method for mounting platform

A material hoist and installation platform technology, applied in the direction of hoisting device, lifting frame, hoisting equipment safety device, etc., can solve the problems of inability to realize the safety protection function of seat belts, inability to solve, no guardrails, etc., to achieve safe and reliable The effect of installation efficiency, prevention of building safety accidents, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

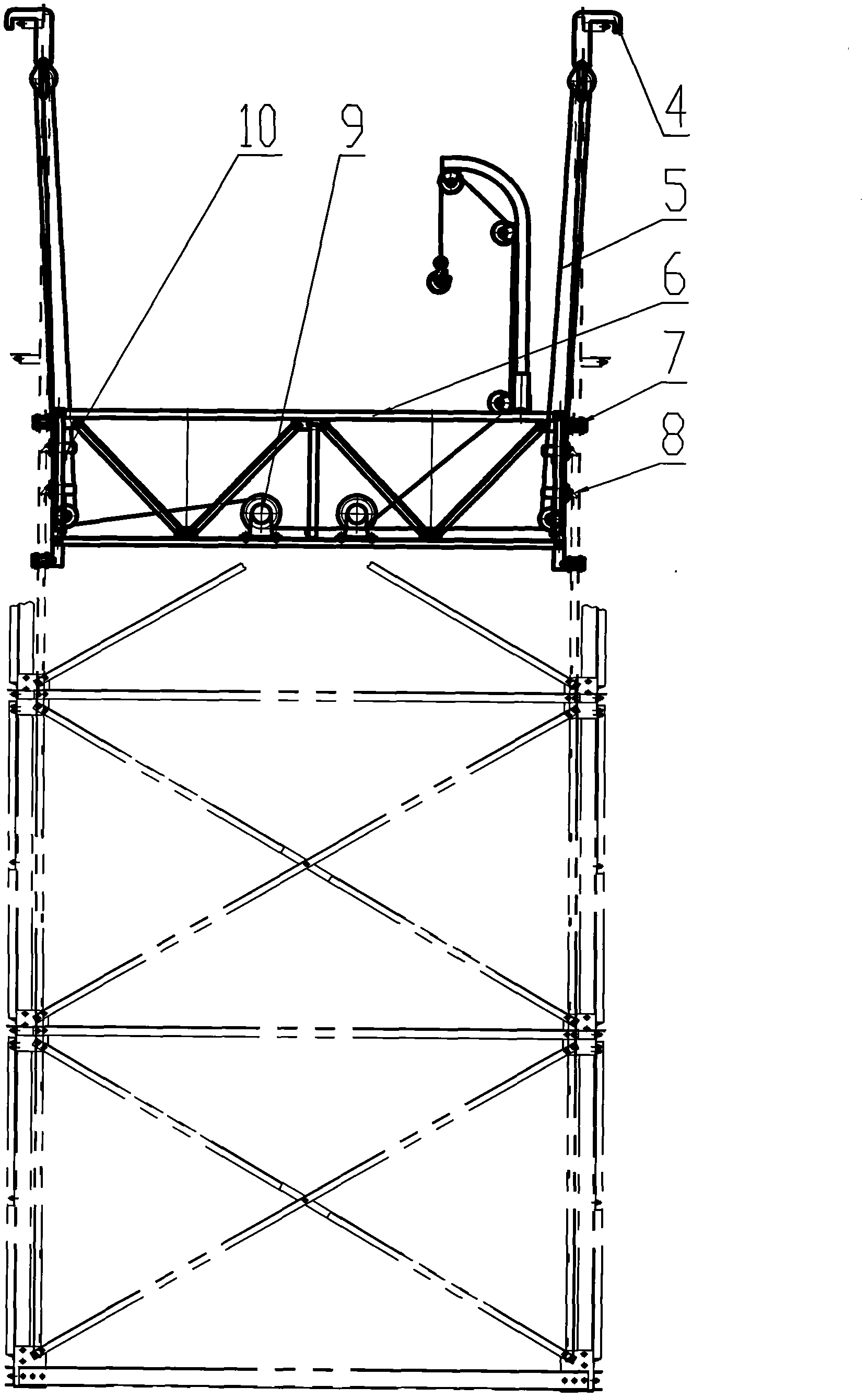

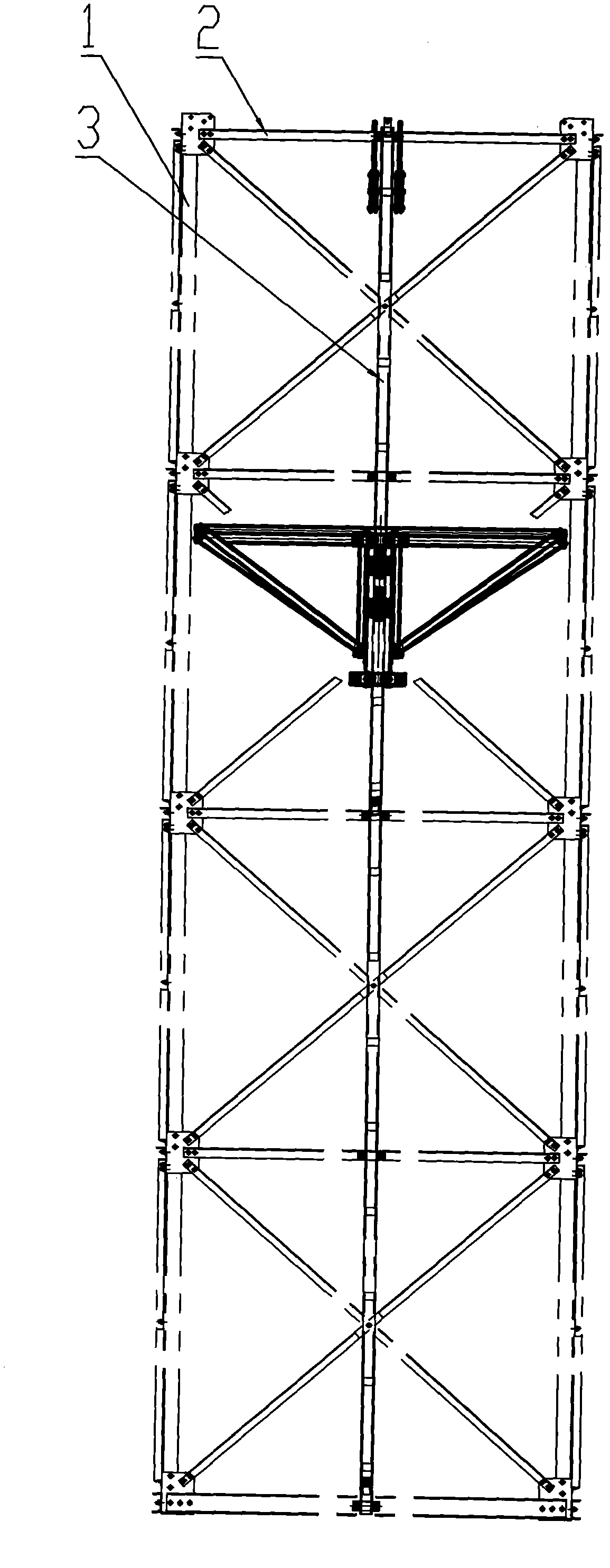

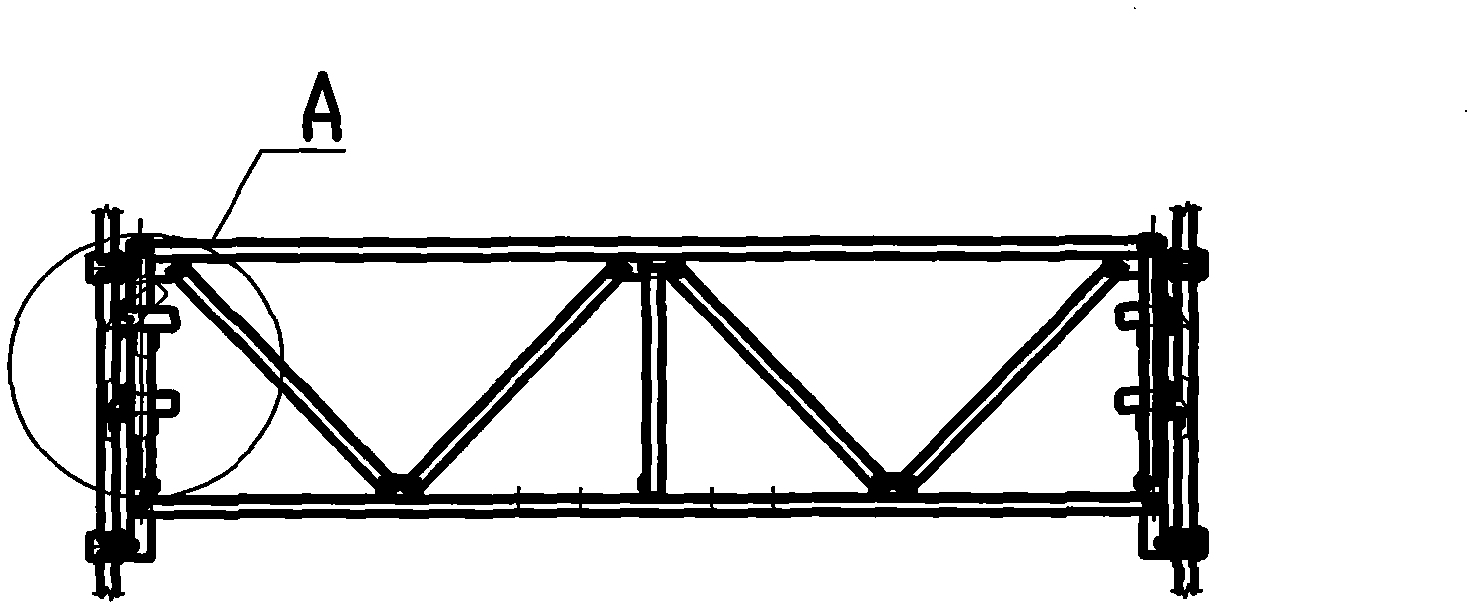

[0039] refer to Figures 1 to 7 , the installation platform of the self-elevating steel derrick material hoist, including the hook 4 for hanging on the highest horizontal rod of the steel derrick, the lifting rope winding system 5, the lifting platform body 6 and the lifting power mechanism 9, the lifting power mechanism 9 is lifted by lifting The rope winding system 5 is connected with the other end of the hook 4, so that the lifting platform body 6 can be lifted and lowered relative to the inner guide rail of the steel derrick. The anti-fall safety knife 8 and the limit plate 10 for restricting the rotation of the anti-fall safety knife 8 are provided with a stop plate 11 for supporting the lifting platform body 6 on the inner guide rail of the steel derrick. The installation platform utilizes the installed steel derrick's highest horizontal pole as a guardrail.

[0040] As a further preferred embodiment, the lifting power mechanism 9 is provided with a rope storage drum. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com