Irreversible thermally induced decoloring printing ink and preparation method thereof

An irreversible thermal and decolorization technology, applied in the direction of ink, chemical instruments and methods, color-changing fluorescent materials, etc., can solve the problems of limited application range and inconvenient use, and achieve the effect of recycling and controllable elimination of printed characters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

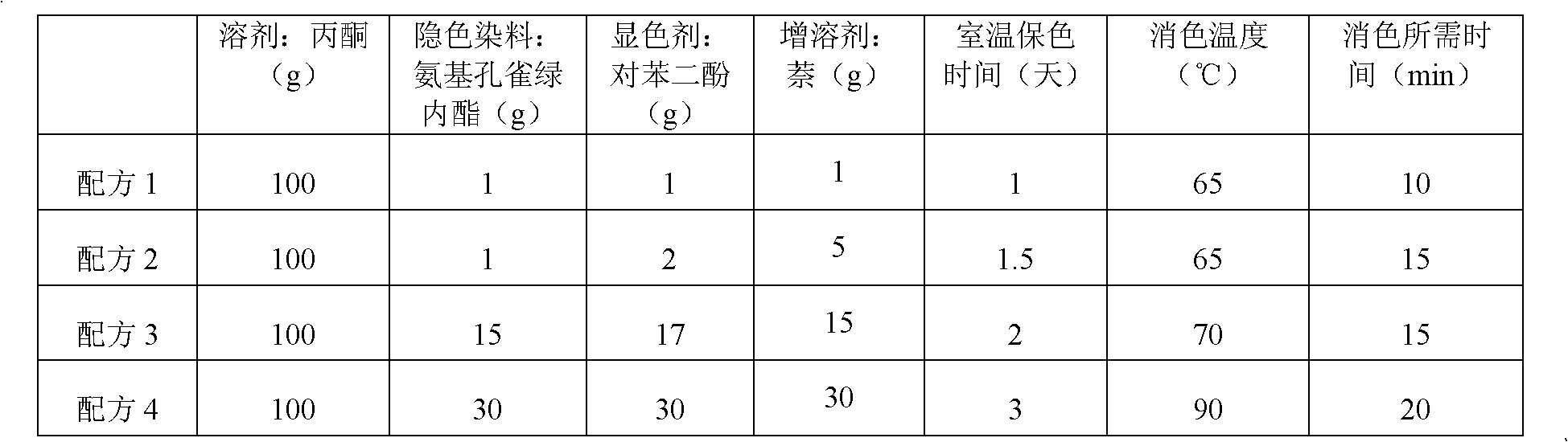

[0033] At 35°C, take 100g of acetone, add color developer: 1-30g of hydroquinone, stir and dissolve, add solubilizer: 1-30g of naphthalene, stir and dissolve, add leuco dye: amino malachite green lactone 1-30g , Stir and dissolve to form a transparent solution and form a leuco ink. Fill the ballpoint pen with ink. When writing on paper, the handwriting will turn green with the evaporation of acetone. The color retention time at room temperature, decolorization temperature and time required for decolorization of handwriting are shown in the table below:

[0034]

Embodiment 2

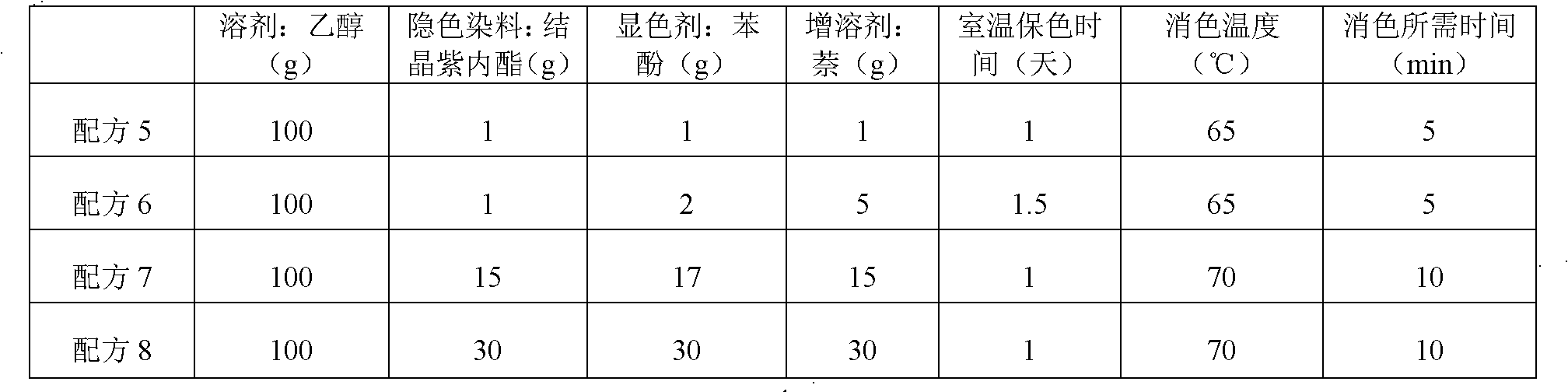

[0036] At 20°C, take 100g of ethanol, add developer: 1-30g of phenol, stir to dissolve, add solubilizer: naphthalene 1-30g, stir to dissolve, add leuco dye: crystal violet lactone 1-30g, stir to dissolve Form a transparent solution and form a leuco ink. Fill the ballpoint pen with ink. When writing on paper, the handwriting will turn blue with the evaporation of ethanol. The color retention time at room temperature, decolorization temperature and time required for decolorization of handwriting are shown in the table below:

[0037]

Embodiment 3

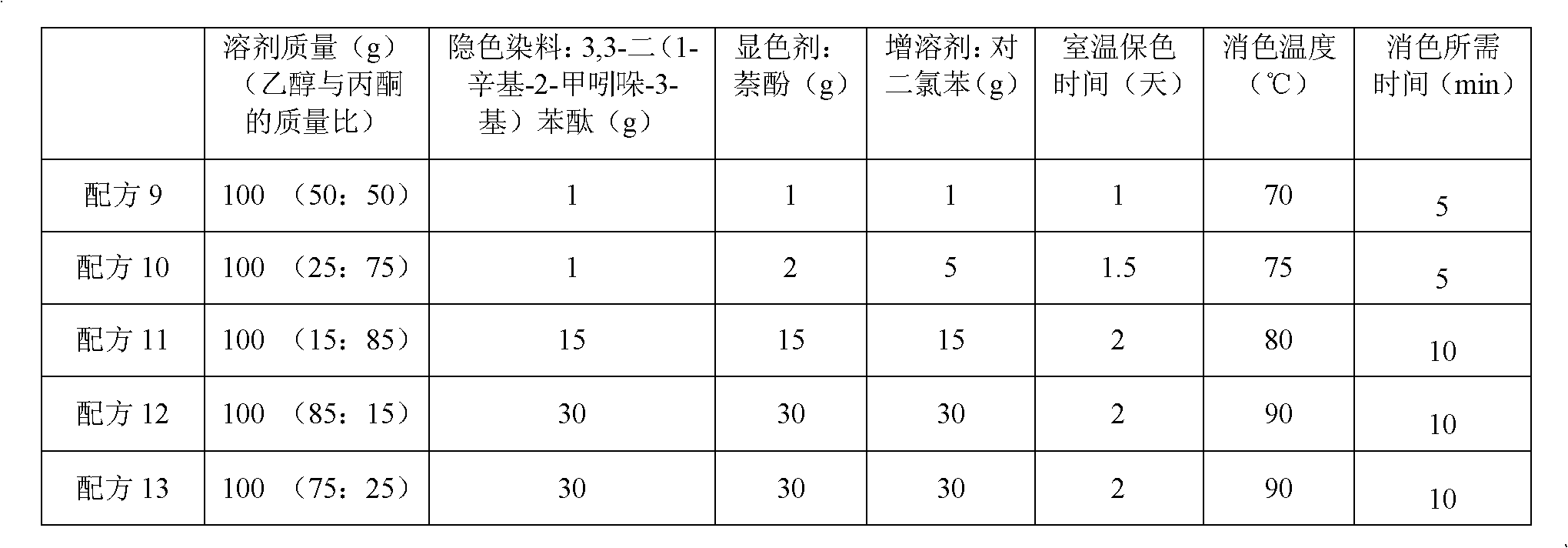

[0039] At 25°C, take 100g of mixed solution of ethanol and acetone in different proportions, add color developer: 1-30g of naphthol, stir and dissolve, add solubilizer: p-dichlorobenzene 1-30g, stir and dissolve, add leuco dye: 3,3-bis(1-octyl-2-indol-3-yl)phthalide 1~30g, stir and dissolve to form a transparent solution and form leuco ink, fill the ballpoint pen with ink, and write on paper , the handwriting turns rose red with the evaporation of ethanol and acetone. The color retention time at room temperature, decolorization temperature and time required for decolorization of handwriting are shown in the table below:

[0040]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com