Aluminum alloy and preparation method thereof

A technology of aluminum alloy and aluminum powder, which is applied in the field of metal composite materials, can solve the problems of oxidation of metal aluminum during sintering, low tensile strength of aluminum alloy, and difficulty in sintering and molding of materials, so as to avoid excessive oxidation, improve mechanical properties, and shorten time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The embodiment of the present invention discloses a method for preparing an aluminum alloy, comprising the following steps:

[0028] 3wt% ~ 20wt% MgZn 2 Nano powder, 0.5wt%-2wt% copper powder and 79wt%-96wt% aluminum powder are ball-milled and mixed to obtain a mixed powder;

[0029] Press-molding the mixed powder to obtain a green body;

[0030] The green body is heated to a semi-solid state under the protection of an inert gas, kept warm and pressurized to obtain an aluminum alloy.

[0031] In the method for preparing aluminum alloy in the present invention, copper powder and aluminum powder are used as raw materials, and the particle diameters of the copper powder and aluminum powder are preferably less than 1 micron; Added MgZn 2 nanopowder, the MgZn 2 The particle diameter of nanopowder is preferably less than 100 nanometers, helps to guarantee the MgZn that contains in the aluminum alloy of preparation. 2 It is nano-scale, so that fine nano-scale reinforcemen...

Embodiment 1

[0052] Take 24g of magnesium powder with a purity of 98% and a particle size of 200 mesh, 130g of zinc powder with a purity of 98% and a particle size of 200 mesh and put them into a grinding tank with a ball-to-material ratio of 10:1, and the grinding tank is placed in a GN-2 high-energy ball mill After ball milling for 2 hours, the mixed powder taken out was solid-phase reacted in an argon atmosphere protection furnace at 460°C for 2 hours, and the obtained micron-sized MgZn 2 , and then crushed by ball milling for 10 minutes to obtain MgZn 2 Nano powder.

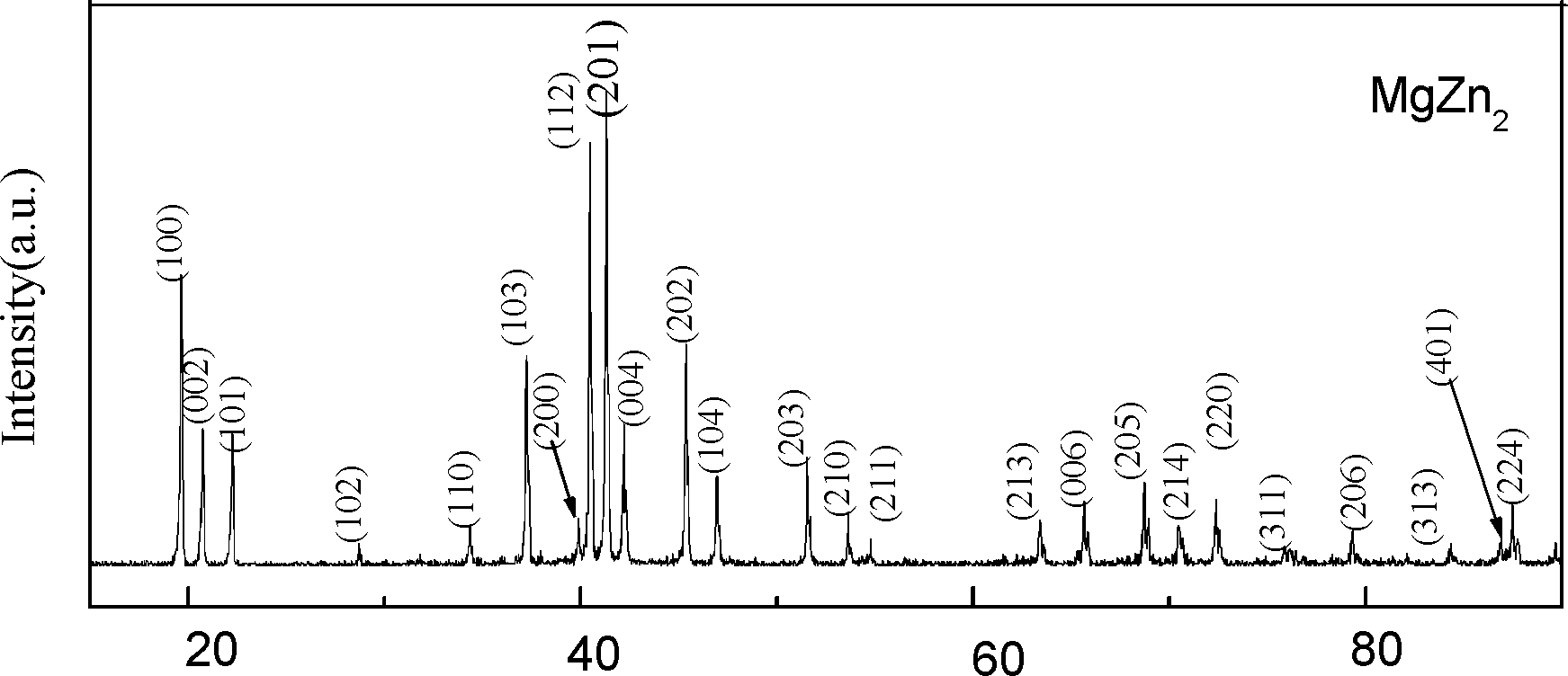

[0053] Carry out XRD analysis to the nanopowder that obtains, the result sees figure 1 , figure 1 MgZn prepared for Example 1 2 The XRD diffraction pattern of nanopowder, result shows, the nanopowder prepared by embodiment is MgZn 2 ,

[0054] Calculated by the Scherrer formula, the obtained MgZn 2 The crystal grains of the nanopowder are smaller than 100 nanometers.

Embodiment 2

[0056] Get the MgZn prepared by 0.15g embodiment 1 2 Nano-powder, 0.05g copper powder and 4.8g aluminum powder were ball milled and mixed for 1.5h, and the obtained mixed powder was put into a steel mold and formed under a pressure of 350MPa. After the formed sample was wrapped with copper foil, it was placed in two Between the anvils, the samples were supported on all sides by pyrophyllite. Heating under the condition of argon, the temperature is 580°C, keeping the temperature for 3 minutes and then pressurizing to 200MPa to obtain a high-strength aluminum alloy.

[0057] The obtained aluminum alloy was polished, and the relative density and tensile strength were measured. The results showed that the relative density of the obtained aluminum alloy was 99.7%, and the tensile strength was 512MPa.

[0058] The obtained aluminum alloy is analyzed by scanning electron microscope, the results can be found in figure 2 , figure 2 The scanning electron microscope picture of the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com