Multilayer thin film preparation system and method thereof

A multi-layer film and process technology, applied in coating, metal material coating process, ion implantation plating, etc., can solve problems such as workpiece deformation, and achieve the effect of improving elasticity, improving process efficiency, and solving deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

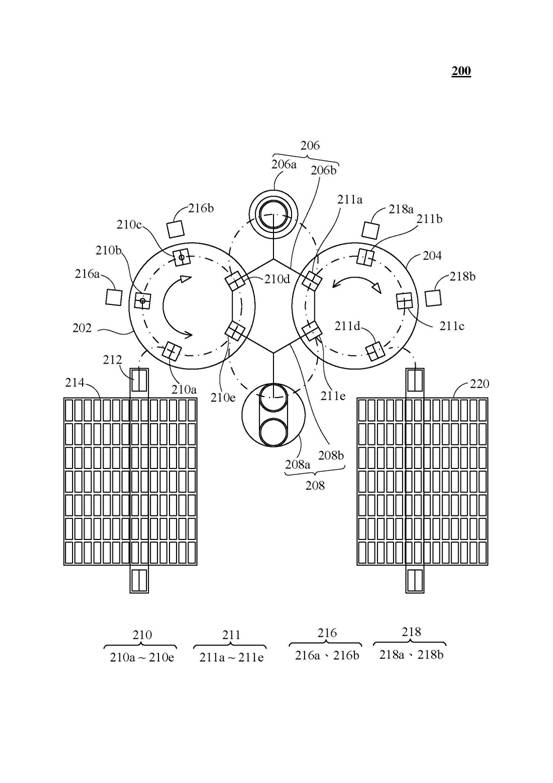

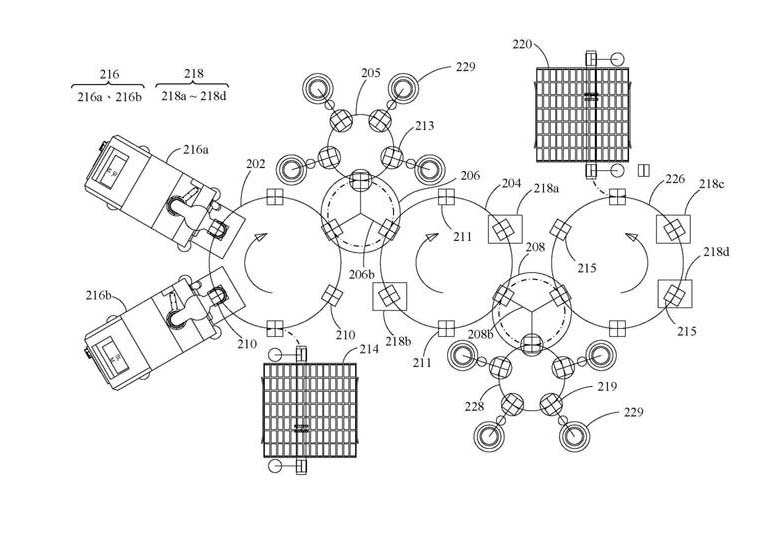

[0017] refer to figure 2 , which shows a schematic plan configuration of the multilayer thin film manufacturing system 200 according to the first embodiment of the present invention. The multi-layer thin film preparation system 200 mainly includes a first circular rotary unit 202 , a second circular rotary unit 204 , a first rotary unit 206 and a second rotary unit 208 . The first annular rotary unit 202 has a plurality of first-type workbenches 210 (such as shown by reference numerals 210a-210e) arranged in an annular order, and these first-type workbenches 210 are used to position a workpiece 212 for the The workpiece 212 performs a number of different functions required by the first process. The second annular rotary unit 204 is adjacent to the first annular rotary unit 202, and the second annular rotary unit 204 has a plurality of second-type workbenches 211 arranged in a circular order (for example, as shown by reference numerals 211a-211e) , so as to perform a plurali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com