Improved latch needle

The technology of latch needle and needle body is applied in the field of improved latch needle, which can solve the problems of unsatisfactory stability of traditional latch needle, insufficient connection between the spring sheet and needle body, and inability to guarantee the knitting accuracy, and achieves a large contact surface. , Improve stability and reduce impact damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

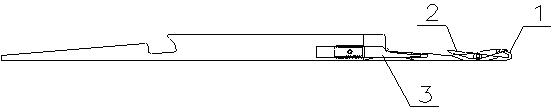

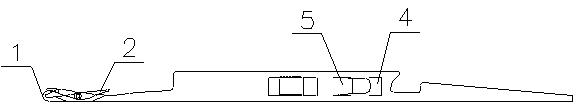

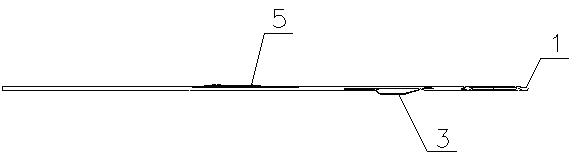

[0013] The invention discloses an improved latch needle, which includes a needle head, a needle neck, a needle body and a needle tail. The needle head includes a needle hook 1 and a needle latch 2. There is a small hole, the thin end of the first spring piece 3 is inserted in the small hole, and the other end is fixedly arranged on the needle body. On the b surface of the latch needle, a long strip-shaped groove 4 is milled in the middle of the needle body. A second spring piece 5 is placed in the groove 4 , one end of the second spring piece 5 facing the needle tail is inserted into the groove 4 , and the other end is fixedly arranged in the groove 4 .

[0014] One end of the first spring piece 3 fixedly arranged on the needle body and one end of the second spring piece 5 fixedly arranged in the groove are both arranged on the needle body by welding.

[0015] The middle parts of the first spring piece 3 and the second spring piece 5 both protrude, and both are higher than the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com