Door lock mechanism

A door lock and driving mechanism technology, which is applied to building locks, other washing machines, building structures, etc., can solve the problems of not producing DC motors, not being able to accommodate the door lock mechanism, and jamming, and achieve cost reduction, reliable operation, and easy operation. The effect of manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] In the following drawings, the same reference numerals are used for the same components, and the similar reference numerals are used for similar components to avoid repeated descriptions.

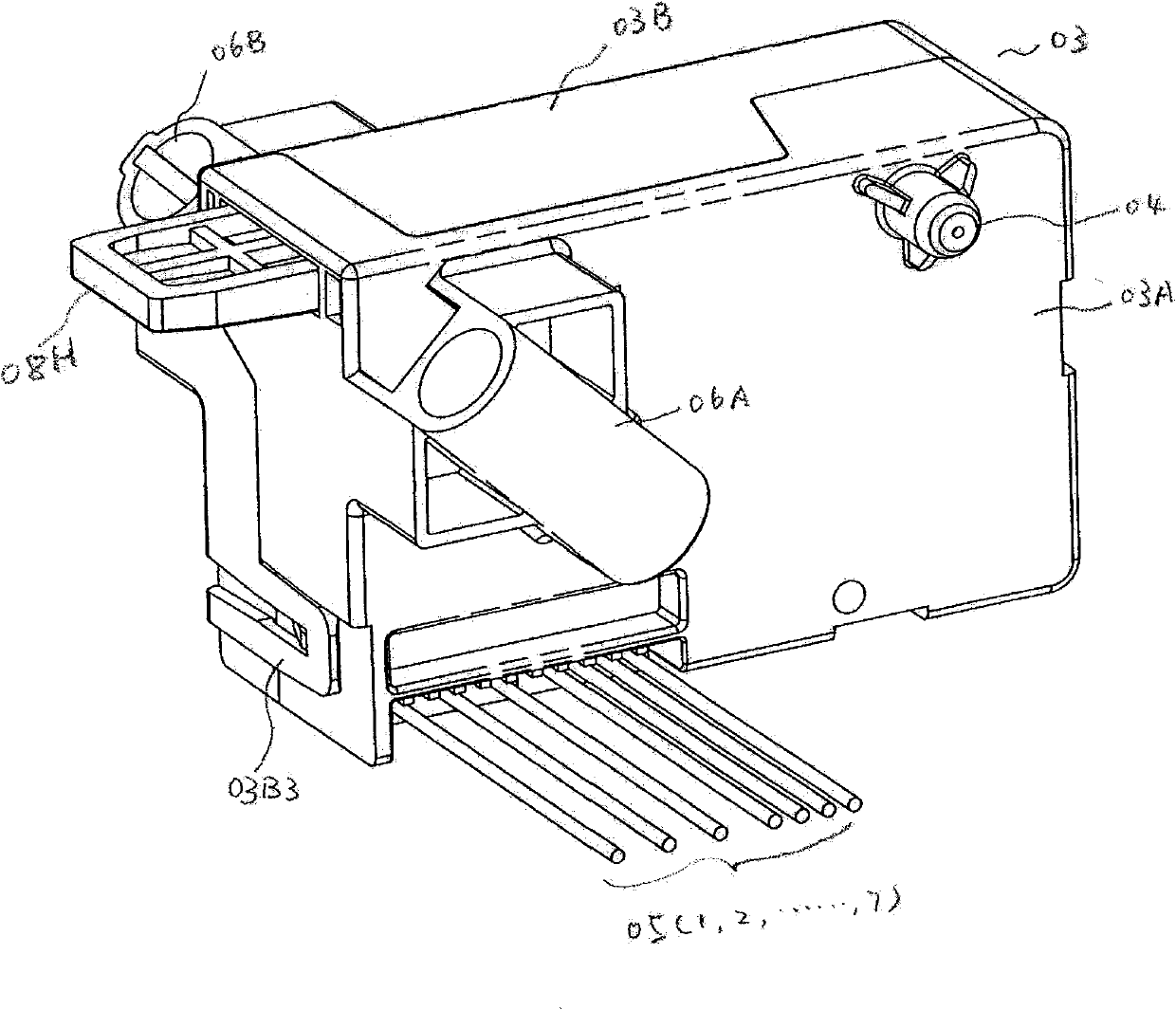

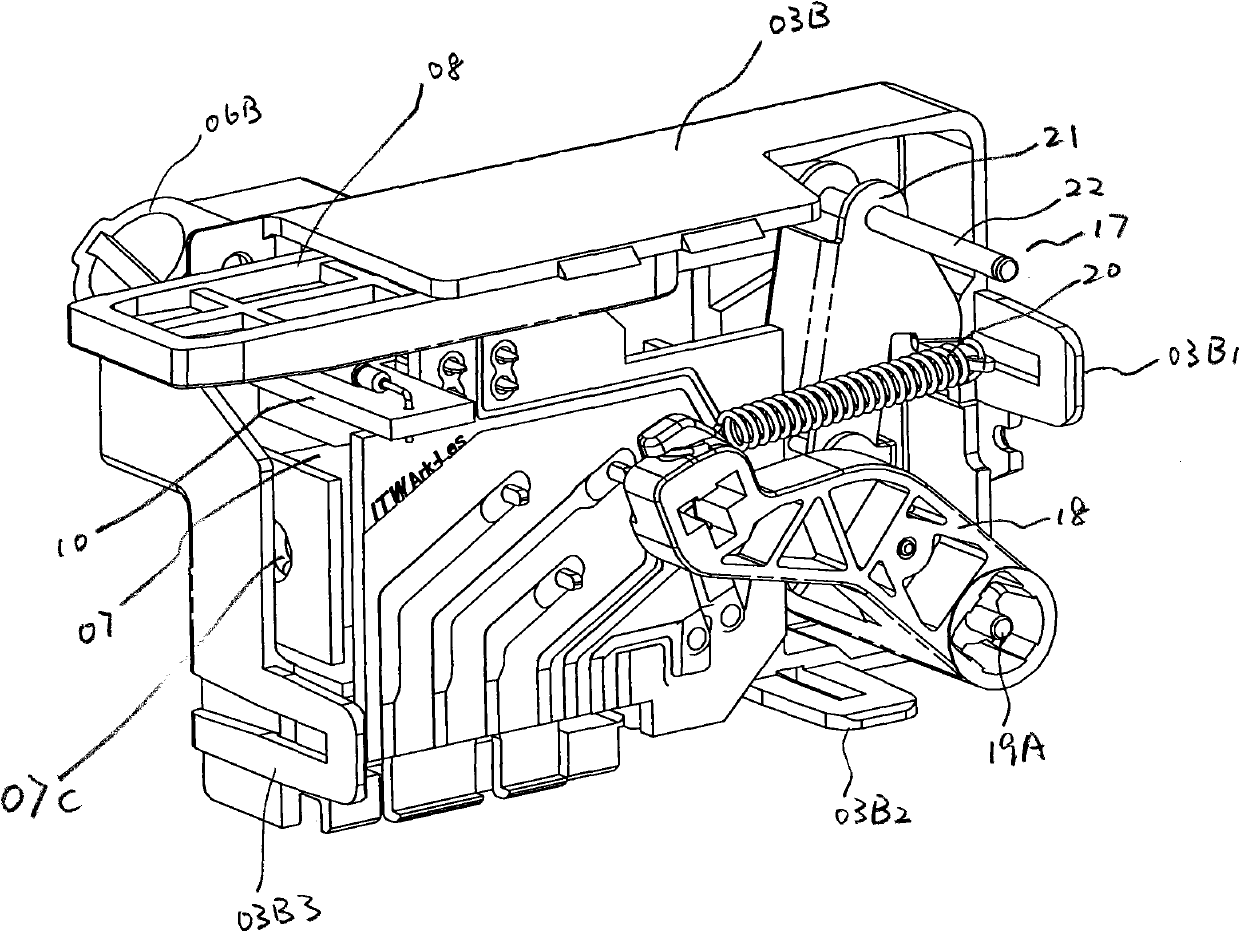

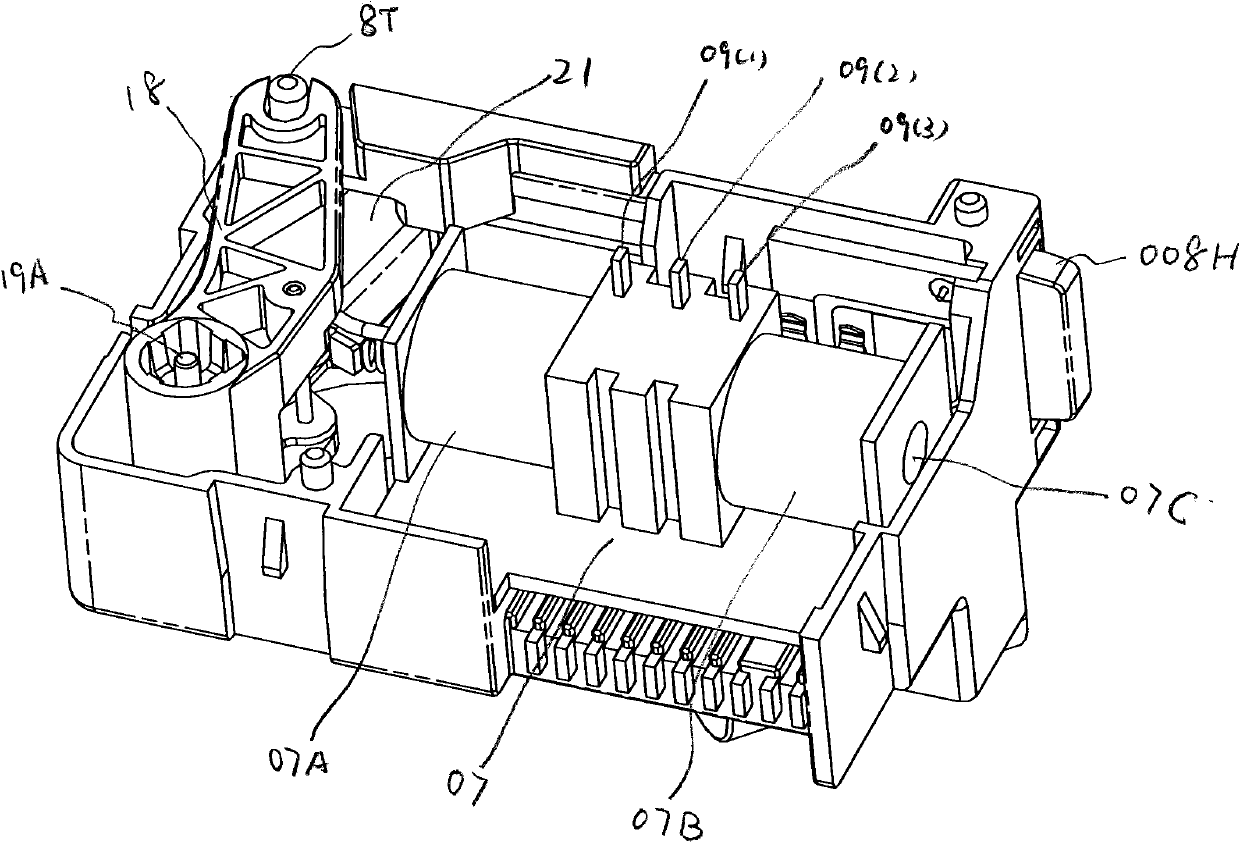

[0049] figure 1 It is an overall external view of the door lock mechanism 002 of the present invention. Such as figure 1 As shown, there is a door lock mechanism housing 003 outside the door lock mechanism 002, including a front housing cover plate 003A and a rear housing cover plate 003B. There is a shaft hole cap 004 on the upper right part of the front housing cover plate 003A, which is used to cover a shaft hole 003C (not shown) on the front housing cover plate 003A, and the shaft hole is used for installing the rocker shaft 22 (see Figure 5 ) of one end 22A, the rocker shaft 22 (see Figure 5) is installed in a shaft hole 003D (not shown) on the front housing cover plate 003B. There is a group of cables 005 (005.1, 005.2, ..., 005.7) at the lower left part of the front hous...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap