Suspended electric steam iron with nanomaterial heater

A nanomaterial, heating element technology, applied in applications, hand irons, household appliances, etc., can solve the problems of non-compliance with the development strategic goals, small heat exchange conduction area, long steam generation time, etc., to shorten the steam generation time, increase The effect of conduction efficiency and shortening of steam generation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

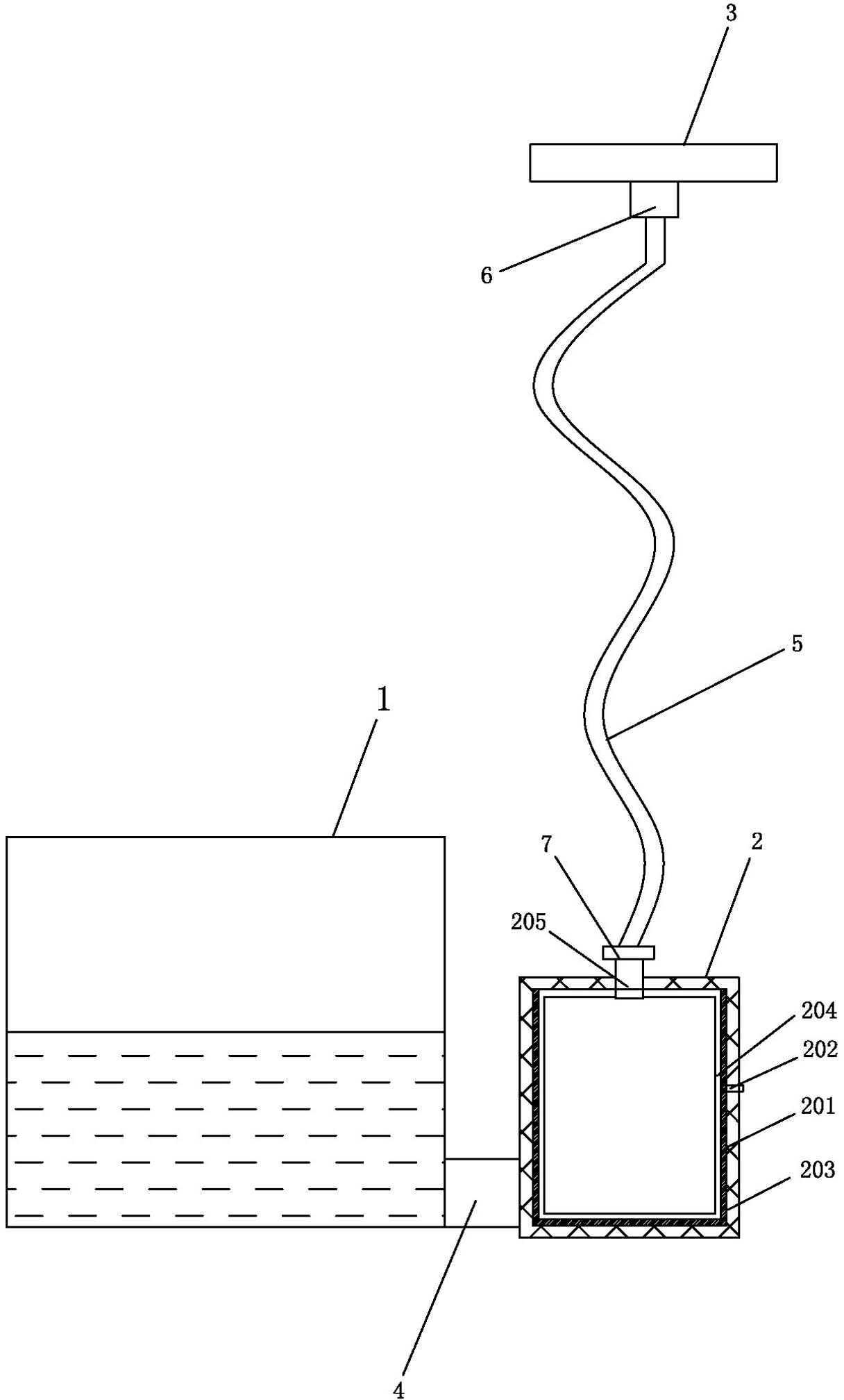

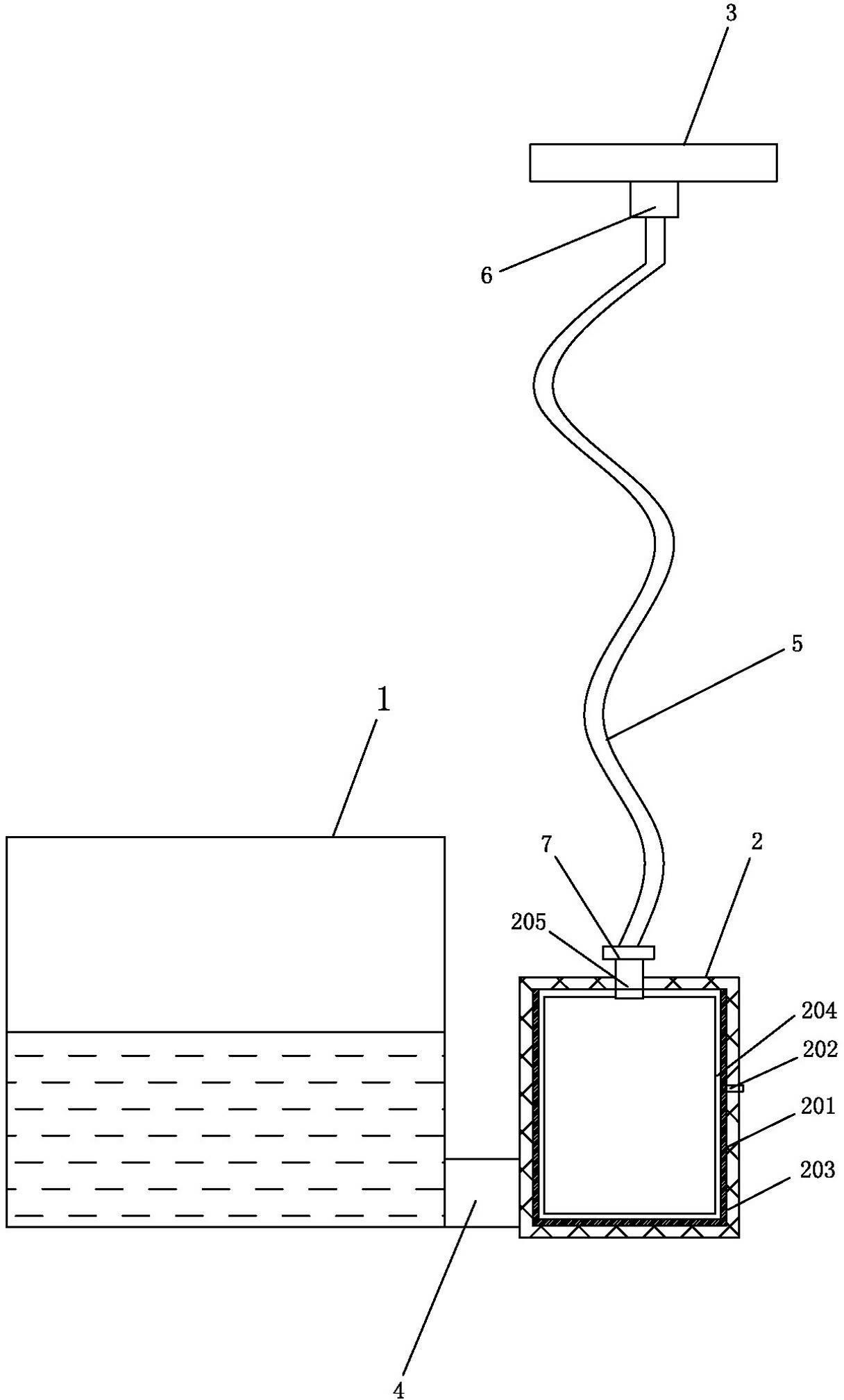

[0011] Such as figure 1 As shown, the hanging steam electric iron adopting nano-material heating element includes a water tank 1, a steam generator 2 and a steam nozzle 3, and is characterized in that: the walls of the steam generator 2 are respectively equipped with nano-heating components from the inside to the outside. Body 201 and nano thermal insulation layer 203, the inner wall of nano heating body 201 is closely attached to a hollow inner tank 204, a water injection device 4 is connected between the water tank 1 and the steam generator 2, and the water injection device 4 communicates with the inner tank 204, and the steam The wall of the generator 2 is equipped with a liquid level and temperature detection protection sensor 202, and the steam spray head 3 is connected to the air outlet 205 of the inner tank 204 through the thermal insulation hose...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com