Logistical method for conveying ballastless tracks in twin-track tunnel in construction

A ballastless track, double-track tunnel technology, applied in tracks, track laying, track maintenance, etc., can solve problems such as high cost and three-dimensional reverse transportation, and achieve the effects of less investment, improved work efficiency, and high work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

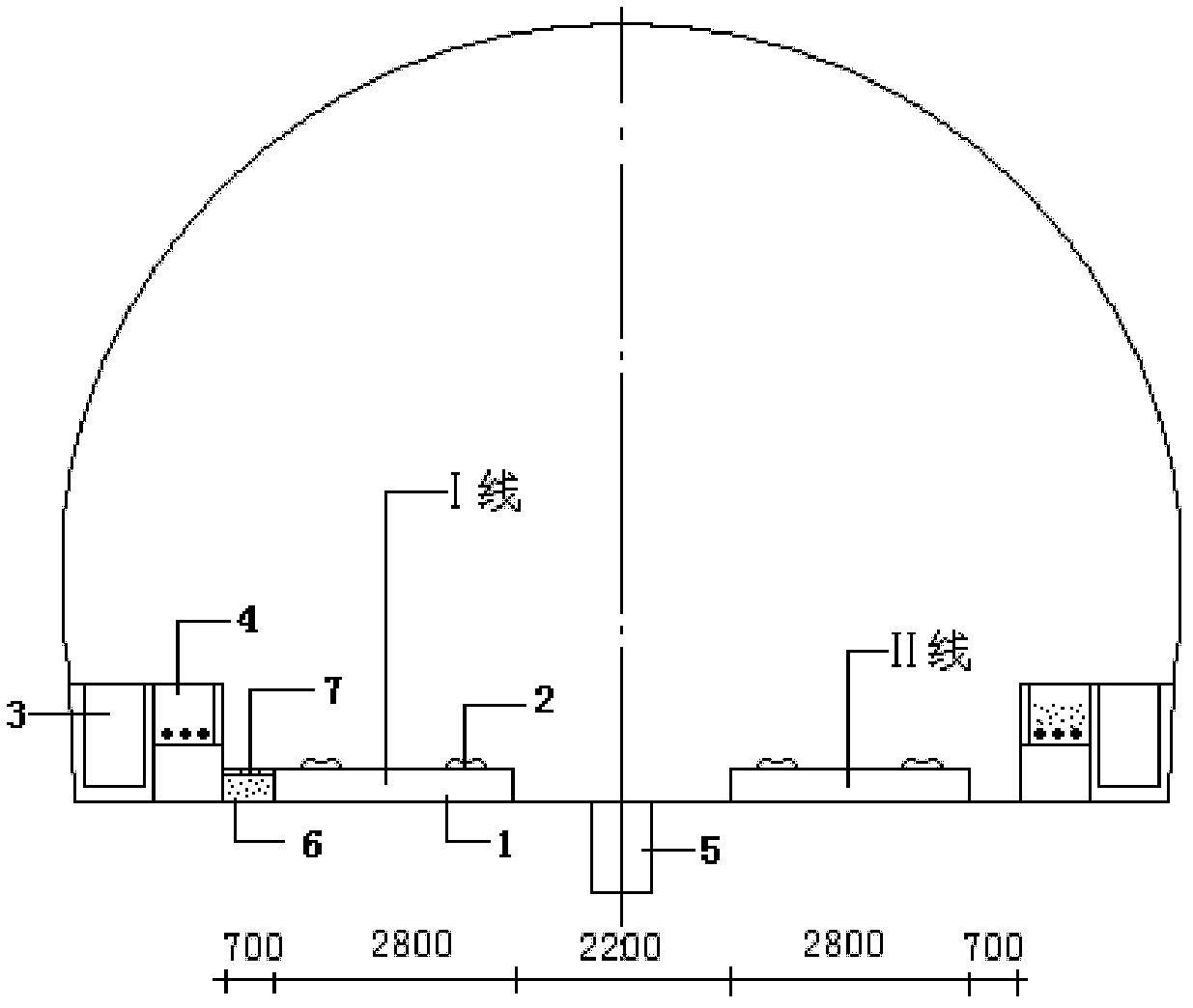

[0020] Consumable materials for ballastless track construction mainly include double-block sleepers, structural steel bars, rail bearing platform 2 (a platform reserved for laying rails), concrete, etc., which are supplied from outside the cave at any time according to needs; turnover tools mainly include tool rails (construction 12.5m long standard new steel rail), formwork, screw adjuster, etc., shall be transported back to the front work area after construction;

[0021] Such as figure 1 As shown, the present invention includes a logistics channel and a logistics scheme.

[0022] Logistics channel: construction logistics channel of line I: borrow the position of line II that has not yet been constructed as the logistics channel for construction of line I; construction logistics channel of line II: use the sand planned to be laid in the cable trough 4 to borrow the sand laid in the completed In the 700mm wide patrol groove 6 on the outside of the I line road bed board 1, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com